(Manufacturer) Rice Bran Granulator Machine / Wheat Bran Pellet Making Machine

Wood Pellet Mill

1. Wood pellet machines’ brief introduction

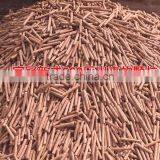

This 1-30T/H Complete machine for make pellet wood line can make the pellets from the waste wood , wood chips , rice husk, sunflower husk , coffee husk wheat bran etc . Compared with the old machine ,it absorbed the essence of horizontal ring die and flat die pellet machine ,solved the insufficient pressure ,die crack problems of horizontal ring die pellet machine ,and overcame the small capacity ,high failure rate of flat die pellet machine .The technological process is rational in succession.

It mainly contains crush process,Drying process pellet making process, cooling process, packing process and waste air handing process(optional), The final pellet has good quality and meet the

Europe standard.

The diameter of the pellets can be 4mm, 6mm,8mm,10mm,12mm, the length can be adjusted

according to the requirement of the client, for example 4cm,8cm,12cm ,etc.

2.The Features of Vertical Ring Die Pellet Machine

(1) YGKJ series vertical ring die pellet machine is an ideal dense compression molding equipment

(2) Less investment , Fast return , No risk;

(3) Vertical feeding, directly in pelletizing room;

(4) Die is static rollers rotate ;materials are evenly distributed around pelletizing room because of centrifugal force ;

(5) Double - layer die two layers both can be used for reduce the cost ,high efficiency and save energy.

(6) Ring die and vertical structure are good for cooling the pelletizing room;

(7) Independent and frequent conversion discharge device can ensure the rate of pellet .

3.Technical Parameters of Vertical Ring-Die Pellet Machine

Model | Power (KW) | Diameter (MM) | Capacity (T/H) | Measurement (MM) | Weight (T) |

YGKJ560 | 90+1.5+1.5+0.37+0.55 | 4-12 | 1-1.5 | 2600*1300*2300 | 5.8 |

YGKJ680 | 160+1.5++1.5+0.37+0.55 | 4-12 | 1.5-2.5 | 3300*1500*2300 | 8.5 |

YGKJ850 | 220+3+2.2+0.37+0.55 | 4-12 | 2.5-3.5 | 3800*1830*3080 | 15 |

4. Commercial Terms of Wood pellet machine :

1. Quantity of Container: The above machines requires container.If you only purchase single

machine , we can use one 20 *container or 40 *container ,If you will buy the wood pellet

production line , we need according to the sections and configurations arrange the containers .

2. Manufacturing time: within 20-60 days

3. Period of validity of the price: within 3 months. After this term, we reserve the right to revise our prices.

4. Time of delivery: In 20-60 days after receipting the deposit. According to our production plan .

5. Payment Terms :30% by T/T advanced payment as down payment,and 70% by T/T before

delivery from factory.

.

The main machine of the pellet production line

Wood chipper ->Rotary dryer ->Hammer mill ->Pellet machine ->Cooler ->Packing machine

If you are interested in our products, please contact me !

Questions of wood pellet machine:

1)The material and its moisture content?

Wood sawdust, Pinus Sylvestris ,albizzia,eucalyptus,corn straw,peanut shell,bamboo ,palm ,

rubber wood,rice husk,stalk and so on;

Before wood chips go into the hammer mill,moisture should be less than 30%,

before wood sawdust go into the pellet machines,moisture should between 13%-17%,

but it is not absolutely,customers should according to the material actual situation to confirm.

2)The capacity you want and how long time will the machine work every day?

We have the capacity from 150kg to 30t/hour.

We will according to the working time match related machines for you.

3)The working voltage and power in your local area?

Generally the price what we quote based on 380v,50hz,3phase.

Related products besides Wood Pellet Machine/pellet mill from ROTEX

Pls kindly tell us the following information:

1. What's the capacity you want?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content?

5. What's the final pellet size do you want?

6. Automatic packing or manual packing needed?

7. What's your country voltage?

Send Inquiry to This Supplier

You May Also Like

-

Good Price Biomass Wood Pellet Machine Rice Huck Pellet Making Machine Peanut Shell Pellet MachineUS$ 690 - 3880MOQ: 1 Set

-

China Factory Wholesale 500KW Industrial Electric Silent Power Diesel GeneratorNegotiableMOQ: 1 Set

-

Humic Acid Fertilizer Pellet Machine(CE)US$ 880 - 99,000MOQ: 1 Set

-

Pellet Briquetting Machine / Rice Husk Pellet Mill PriceUS$ 25,000 - 25,000MOQ: 1 Set

-

Wood Pellet Mill Machine for Wood Dust Pellet PressUS$ 1,000 - 10,000MOQ: 1 Set

-

Energy Saving Straw Coal Briquette MachineUS$ 2,000 - 3,000MOQ: 1 Set

-

Diesel Flat Die Small Pellet MillUS$ 500 - 1,000MOQ: 1 Set

-

Industrial Complete Flat Die Wood Pellet Production LineUS$ 20,000 - 25,000MOQ: 1 Set

-

Factory Directly Wood Pellet Press, Wood Pellet Press Machine, Gemco Supply Wood Pellet MillUS$ 3,000 - 4,000MOQ: 1 Set

-

Hot Sale and Best Quality Wood Briquette Machine Screw PressNegotiableMOQ: 1 Set