Specifications

PVC pipe Belling Machine1.200mm - 500mm

2.low price,qualified

3.easy to operate

4.national Standard

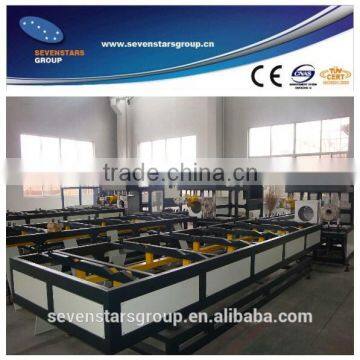

Full Automatic UPVC/PVC pipe belling Machine

Main technical parameter:

pipe expand range (out diameter) | Φ200-Φ500mm |

control method | full-automatic control |

hydraulic system pressure rate | 20 – 50 Mpa |

Oil label | No.40/hydraulic oil |

Hydraulic pump power | 2.2KW |

Hydraulic pump vavle | from Taiwan |

Hydraulic cylinder,stem,hydraulic pipe | Festo of German |

Heating power | 6KW |

Heating barrel highest warming | 250 |

Air pressure | 0.4~0.6Mpa |

Cooling water pressure | 0.2~0.3Mpa |

CPU | PLC: Simens of German |

Detection components | Switch(Schneider) |

Temperature control unit | Omron of Japan |

Common electrical equipment | joint-venture Schneider |

Machine set weight | 1.5 T |

Belling center | 1000mm±50mm |

Configuration:

1.The whole operation process of the belling machine both adopt human-machine interface touch screen from Japan Mitsubishi by PLC , the belling is operated automatically.

2. The heating mode adopts heating pipe in interior and exterior by double work position infrared ray, the hot air circulating equipment is installed the interior of the heating box,it makes the heating of the pipe fast and symmetrical and even improve the work efficiency .

3. The process of the clamp and belling both adopt hydraulic equipment,the hydraulic pump adopts variable vane pump from Taiwan.

4. The cooling system adopts vacuumize and water cooling mode,the effect is higher twice than the wind cooling.

5. Photoelectric switch adopts theautonics.

6. Pneumatic element adopts thequanwei .

The spare parts with the machine:

a.A copy of the Chinese- English instruction book

b.Inner hexagon spanner : 1 set

c.Photoelectric switch: 2 pieces; panel knob: 2 pieces; contactor: 2pieces; Protective tube: 1 set.

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece