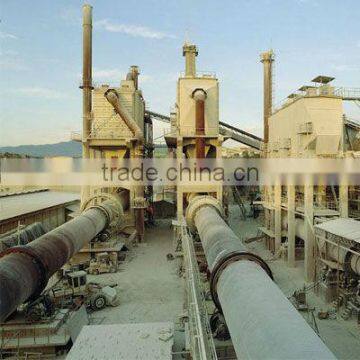

Introduction of calcined magnesite rotary kiln:

calcined magnesite rotary kiln is known as magnesium metal rotary kiln and it is used in: chemical products - magnesium sulfate, magnesium sulfate heptahydrate, In refractory aspect it is the main raw material for production of the steelmaking magnesium ball bottom material, In the building aspect,it is widely used in the production of container, fire board, arts and crafts, vegetable greenhouses, wall insulation boards, activity boards, asbestos and other. It can increase wear resistance, good adsorption, a lower melting point and can change metal lattice structure (fine),so it is used in paint painting refractory bricks, magnetism material, ceramic, rubber tires, and so on.

Structure of calcined magnesite rotary kiln:

calcined magnesite rotary kiln is made of cylinder, gear, prop, gear wheel bearing device, kiln, kiln sealing parts, kiln hood and combustion devices. Cylinder of magnesium oxide rotary kiln is the heated rotary parts and is made of quality sedation steel plate welded. Due to the particularity of the calcination process, our furnace adopt diameter changes type kiln body, Through the wheel with bearing block in 2 to 4 on the sliding or rolling bearings devices, and in one block or block support device set a mechanical or hydraulic gear wheel, magnesium oxide rotary kiln control the axial movement of the cylinder; The transmission device of magnesium oxide rotary kiln speed rotary according the requirements through the ring gear in the cylinder central cylinder rotation; Due to the requirements of installation and maintenance,large calcined magnesite rotary kiln set auxiliary transmission device ,which make kiln body speed in a low rotary;In order to prevent cold air into and gas dust overflow the tube,we set reliable preheater and kiln head sealing device in the feeding end and discharge end for the calcined magnesite rotary kiln cylinder.

Advantages of calcined magnesite rotary kiln:

calcined magnesite rotary kiln's structure is simple, convenient and reliable control in the production process, less wearing parts, high rate of operation,so it is the high grade cement equipment in the cement plant, and it is widely used in the metallurgy, chemical industry, construction and other industries.

Technical parameters of calcined magnesite rotary kiln:

| Model (m) | Production Capacity (t/d) | Host Machine | Speed Reducer | Weight (t) | Remark | ||

| Model | Power(kw) | Model | Ratio | ||||

| 18x26 | 72 | JZT2-72-4 | 30 | JZQ750-I-I | 48.57 | 66 | |

| 1.9/1.6x39 | 72 | JZT2-72-4 | 30 | JZQ750-I-I | 48.57 | 66 | |

| 1.9x36 | 84 | YCT315-4A | 37 | ZS110-5-III | 78.19 | 85.9 | |

| 2.2x45 | 98.4 | JZT82-6 | 55 | ZA125 | 93.93 | 104 | |

| 2.5x40 | 160 | Z2--92 | 40 | ZS125-2-I | 134.9 | 143 | |

| 2.5x45 | 170 | JTZ82-4 | 45 | ZS125-4-I | 69.71 | 148 | |

| 2.5x50 | 180 | ZT3-72-4 | 30 | ZS145-9-V | 122.8 | 173 | |

| 2.5x60 | 168 | YCT355-4B | 75 | ZS165-7-II | 99.96 | 222 | Bauxite calcining kiln |

| 3x48 | 360-480 | YCT355-4B | 75 | ZS145-7-II | 100.4 | 170.6 | |

| 3.1/2.5x78 | 216-240 | Z4—225-31 | 75 | ZS165-2-II | 57.17 | 268 | |

| 3x48 | 700 | ZSN4-280-21B | 110 | MSY56-28-II | 28 | 244 | decomposition out the kiln |

| 3x100.94 | 450 | ZSN4-280-21B | 90 | NZS995-90-VI-L | 90 | 526 | more cooling tube |

| 3.2x50 | 1000 | ZSN4-280-21B | 160 | MSY56-28-II | 28 | 252.4 | decomposition out the kiln |

Send Inquiry to This Supplier

You May Also Like

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Separator Rotar Cement Mill Liner PlateUS$ 256 - 256MOQ: 1 Piece

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set