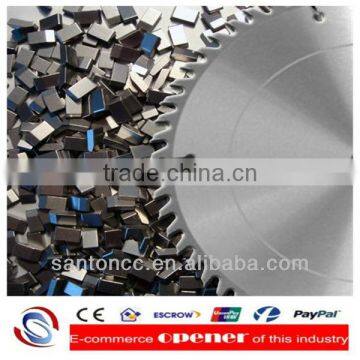

Carbide saw tips

Advantages:

1.Made from 100% virgin raw material

duced with advanced equipments and perfect workman ship

3.All products go through in-process and final inspection

4.Stable and continuous production ability

5.Best quality along with reasonable price

Grade:

YG6,YG8,YT15,ZP10,ZP20,ZK10UF,ZK20UF,etc

Type:

SNMG,SNMM,SNGN,SNMA,SNGA,SCMT,CNMG,CCMT,CCMW,CCMM,TNMG,TNMM,TNMA,TNGA,TCMT,TPGA,DCMT,DNMG,DNMM,DCMW,DNMA,etc

Coating:

VD,CVD,MT-CVD,coating also can be customer's requirement. All sizes with different chip-breaker.

Chengdu Santon cemented carbide Co.Ltd can supply our customers various types and grades of cemented carbides inserts including ISO turning inserts, Aluminum turning inserts, Profile turning inserts, Heavy turning inserts, Cermet inserts, PCBN&PCD inserts, Parting, Grooving inserts, Milling inserts and so on.Our inserts are optimized design with low wear, low friction and long life.

If you are interested in our products, please feel free to contact us. Your special design is also welcomed here.

Main product

Application Field

brief introduction

Inside the packaging and the outer box

Why choose Carbide Inserts

1.Higher speeds and feeds allow more aggressive machining. Carbide

insert tools hold their cutting edge hardness at the very high machining

temperatures created at high speeds and feeds. High speed steel tools must be run

at lower speeds and feed as their cutting edge softens at a much lower

temperature.

2.Hold size longer than high speed steel tools. The carbide insert provides exceptional

wear resistance at the cutting edge.

3.Last longer due to carbide insert forming surface resisting wear as the chip being

formed flows over the tool. Cratering is minimized and the tool's structural

strength is maintained. High speed steel tools crater rapidly and structurally fail

prematurely when machining abrasive materials.

4.Carbide Insert are high hardness and good abrasion resistance.

FAQ

Q:What is cemented carbide ?

A: Cemented carbide is a hard material used in machining tough materials such as carbon steel or

stainless. Carbide tools can also withstand higher temperatures than standard high speed steel tools.

Q:What are the key properties of cemented carbides I should be concerned with when selecting a grade for my application?

A: The key properties of cemented carbides that define their performance level for different applications

include abrasion resistance (directly related to the hardness of the grade), fracture strength, and fracture

toughness.

Q: Which properties are important in metal cutting applications?

A: Depending upon the type of metalcutting operation (turning, milling, drilling, etc.), different combinations

of properties is needed in order to obtain optimum results. Grades employed for metalcutting applications are usually based on fine to medium

hard phase grain sizes (0.5 to 1.5 mm) and low to medium Co contents (6 to 15 wt.%).

Q: Which grades are useful in metal forming applications?

A: Grades employed for metalforming applications are typically based on coarse grain sizes (3 to 8 mm) and high binder contents (15 to 30 wt. %).

Q: Which grades are useful in earth drilling or boring applications?

A: The best compromise is usually arrived at by using grades that are based on coarse grain sizes (3 to 8 mm)

and relatively low Co levels (6 to 16 wt. %).

Q: How can I choose the most suitable products for my applications?

A: 1.Correct installation site depends on specific size and drawings. Especially for dies processing,

drawings can ensure the finished products are qualified.

2. Processing objects and working environment is determined by cemented carbide grades.

Products' lifetime can be greatly extend if grades are right.

See what company you will work with:

1.ISO9001

2.OEM and ODM accept

3.100% Virgin raw materials

4.Can help you to solve all the problems

5.Low your cost in products purchase,insurance

6.A professional supplier carbide inserts over 10 years

7.Main marker:European,America,Middle east,South Ameican, Australia

8.Completely Production Line. From Raw Material to Delivery, all links are under our comtrol.

contact

Send Inquiry to This Supplier

You May Also Like

-

AVENTCIS Original Authentic Anvochi Cylinder Seal Repair Kit 1827009907NegotiableMOQ: 1 Piece

-

CNC Lathe Machining Machinery Rotating Shaft Stainless Steel SpindleNegotiableMOQ: 1 Set

-

Best Price Cnc System Unit Screen Display A02B-0309-B502 oi mf Fanuc ControlNegotiableMOQ: 1

-

12PC High Carbon Steel Metal Blade Offset Thickness Gauge ToolUS$ 1 - 30MOQ: 600 Pieces

-

Tungsten Carbide Insert for CNC MachineUS$ 1 - 1.5MOQ: 1 Kilogram

-

Ice Storing BoxNegotiableMOQ: 1

-

The High Quality Probe From China Machine Tool ProbeUS$ 50 - 100MOQ: 1 Set

-

Bag Closing Machine Spare PartsNegotiableMOQ: 1

-

Antistatic Basin of Pure Aluminium,,garden Tools,hand Tools,power Tools,ISO9001,UKASUS$ 10.83 - 38.33MOQ: 2 Pieces

-

21Spindles/11Spindles Drilling Head Noise Aborsbing BoardNegotiableMOQ: 3 Pieces