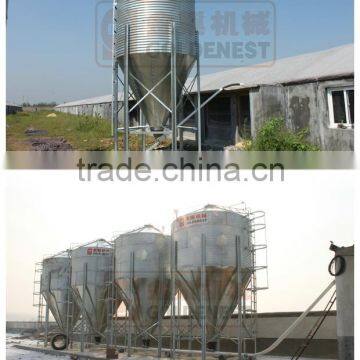

DESCRIPTION: Goldenest machinery established in 1987, located in coastal city: Qingdao China. It is a professional manufacturer and exporter in poultry and livestock field. Here I introduce one of our main products :SILO/FEEDS TOWER

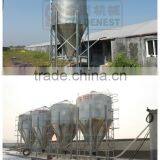

1.All The Material Is Heavy Galvanized with at least 275G;

2.High Accuracy, Adopting Advance Processing Method And Tightness Meets Customers Request;

3.Keep The Feeds Fresh and Nutritious by Storage Bins;

4. No Dew Will Generate In the Silo In Large Temperature Difference, Eliminates Opportunities for Feed To Turn Moldy;

5.Encapsulated Bolts On Outside of Bins to Prevent Corrosion;

6.Wide Range of Capacities From 3 Tons to 20 Tons;

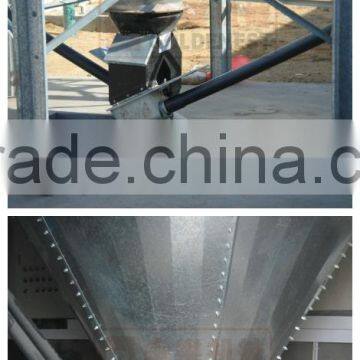

1.Delivery By Chain-disc, Anti-wearing;

2.The Plastic Plate can not be Loose Because of the Special Process, Prevent the Feeds Sticking Together.

1.The Triangle Discharge is Made of High Galvanized 275g, Anti-Corrision, Long Life Usage;

2. Inner is Polished to Guarantee the Feeds Delivery Smoothly, No Sticking;

3. Reasonable Angle for Feeds Convey;

1.The Ladders is Made of Galvanized Steel with Guard Rail, It has Better Strength, Smooth Appearance, Heavy Load,Pepoles can Climb Up Easily;

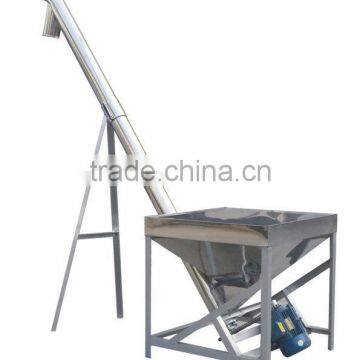

MATERIAL: Stainless Steel / Heavy Galvanized Steel

1. Driving System 2. Silo 3. Feeding Tube 4. Corner System 5. Sensor 6. Automatic Feed Drop System 7. Feed-drop System 8.Metering Feed Dispenser 9.Electrical Control System 10. Dry & Wet Feeder

Drive Power: 1.5kw/2hp

Line Speed: 37m/min

Volume:1580kg/h

Feed Pipe Occupancy Rate: In condition The Feed Density is 650kg/m3, 66% Pipe is Filled, About 1.2kg/meter. Feed Will Be Stocked.

Send Inquiry to This Supplier

You May Also Like

-

Large Cattle Feeder Trough Concentrated Automatic Feeder Calf Cattle Feeder With RoofUS$ 6.94 - 27.76MOQ: 10 Pieces

-

PE Animal Feeder With Rotomold Making , China Rotomould Supplier , Cheap Plastic FeedersNegotiableMOQ: 1

-

Electric Rotary Broiler/automatic Rotary Kebab Grill Machine/kebab Skewer Grill MachineUS$ 300 - 900MOQ: 1 Set

-

New Product Eco-friendly Bamboo Dog Pet FeederUS$ 1 - 20MOQ: 1000 Pieces

-

Pet Dog Puppy Cat Automatic Screw Feeder Machine Water Dispenser Food Dish Bowl Feeder BottleUS$ 0.8 - 0.8MOQ: 100 Units

-

Pet Drinker Bowl/dog Water FeederUS$ 0.2 - 0.2MOQ: 3000 Sets

-

2016 Lovely Wooden Pet Food Bowl for Animal, Top Fashion Wodoen Pet Food Bowl W06F013US$ 1 - 8MOQ: 1000 Pieces

-

Auto Pet FeederUS$ 4 - 10MOQ: 5000 Pieces

-

Cheap Plastic Pet Food ScoopUS$ 0.2 - 0.6MOQ: 5 Cartons

-

Birdscapes Clear Window Feeder With Suction CupUS$ 1 - 1.5MOQ: 3000 Pieces