Machine Application

(1) PU rigid foam: refrigerator, freezer, sterilizer, garage door, lamp board, decoration bar, mirror frame, plastic flowers, synthetic wood, etc.

(2) PU semi-rigid foam: bumper guard, shock-proof elastomer, surfboard, toys, etc.

(3) PU integral skin foam: car interior trim, door trim, steering wheel, skin of armrest, handle parts of tennis and badminton racket, etc.

(4) PU flexible foam: cushion of sofa, motorcycle, bicycle, car, etc.; back cushion of sofa and car; memory pillow, etc.

(5) Shoes industry: slippers, casual shoes, safety shoes, sandals, etc.; shoe soles (insoles, outsoles), integral upper of shoes, etc.

Disc Shape Production Line

1. At Least 60 Working Positions

2. Automatic Production Line

Half-Disc Shape Production Line

1. 24, 36, 48 Working Positions

2. Semi-Automatic Production line

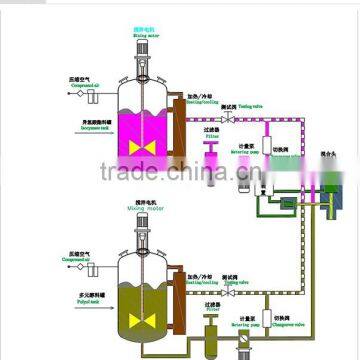

Two-Component Silo

Three-Component Silo

Injection Head

1. Pin Valve :No Block; No Abrasion

2. Self-Clean

3. Easy to Operate & Maintain

4. Precise Injection

Electric Control System

Parts of Foam Machine

Trade Term: FOB

Payment Terms: T/T.

Payment Condition: 30% deposit in advance. 70% balance before delivery.

Delivery Time: 30-35 working days after deposit.

Packing: PE Wrapping / as customer's request

Shipment: By Sea.

Send Inquiry to This Supplier

You May Also Like

-

Panqi High-efficiency Hot Melt Foam Hot Melt Machine Processes EPS, EPE Waste Foam Pearl Cotton From Electronics, FurnitureUS$ 1153 - 1696MOQ: 1 Set

-

CE APPROVED XPE Foaming MachineUS$ 1,000 - 50,000MOQ: 1 Set

-

Best Used Protable pu Foam Machines for Roof PanelUS$ 1 - 6,000MOQ: 1 Set

-

Plastic Machinery With Competitive PriceUS$ 1,000 - 3,000MOQ: 1 Set

-

EPS Polystyrene Foam Cup Making MachineUS$ 9,000 - 290,000MOQ: 1 Set

-

Large-capacity Low-cost Icf Machine for Blocks Made of Eps and CementUS$ 250,000 - 500,000MOQ: 1 Set

-

Plastic Foam Crushing Hot Melting Block Making Machine Waste Foam Thermal Melting Tuo MachineNegotiableMOQ: 1

-

EPS Foam Balls Making MachineUS$ 1 - 3MOQ: 1 Piece

-

EVA Foam Press/PE Foam Press/EVA Foaming Machine/PE Foaming Machine/EVA Vulcanizing PressNegotiableMOQ: 1 Set

-

QYYX-2150 Profile Foam Cutting MachineUS$ 12800 - 15000MOQ: 1 Set