Specifications

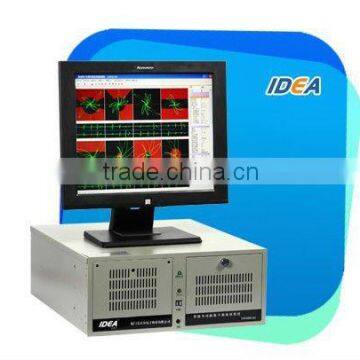

ET EDDY CURRENT FLAW DetectorET Detector

eddy current testing instrument

ISO,GB,ASTM ,EN,JB

ET EDDY CURRENT FLAW Detector

ET Detector

eddy current testing instrument

ISO,GB,ASTM ,EN,JB

Please contact me: ) EXPORT (at)

Main Technical Data

1. Testing channel: 1-8, can be extended to 128 channels

2. Frequency range: 50 Hz~10 MHz,to meet various metal material testing requirements.

3. Gain: 0 dB ~ 99 dB, continuously adjustable, the work of each file 0.5dB step

4. Phase: 0 ~ 359 °, continuously adjustable,continuously adjustable, precision 1 °

5. Gain ratio: (X/Y)0.1~10.0

6. Testing speed: >300/min

7. Adjustable probe drive rank: 1~8, the real sense multi-function

8. Fast digital / analog electronic balance

9. non-amplitude, unsymmetrical phase alarm region setting

10. Various display: impedance, time base display

11. Digital Filtering: High-pass frequency (0Hz ~ 2000Hz), low-pass frequency (0Hz ~ 2000Hz)

12. Dalayed hardware output alarm, real-time hardware output alarm

13. Sound-light alarm output

14. charging power supply: 110V ~ 220V

15. Capable of delayed marking, fixed length marking, high accuracy up to 0.001S/1MM

16. Automatic balance time: 1~1000 minute

17. Inner or outside clock for choice

18. Able to remove interfering signals from both ends of the tested workpiece.

19. Mass storage of various test procedures and test data

20. Eddy current testing signals playback, and the defects amplitude, phase and digital value measurement

21. Automatically record and display the number and the position of defects.

22. Display modes: solid line and blanking display

23. Blanking display coefficient: 1~100

24. English and Chinese operating languages, on-line help

25. Rectangular coordinate system and polar coordinates background for choices

26. Automatically display the date and time

Applied to the ndt (non-destructive) detecting of metal material. For example, weldless steel tubes, petroleum pipes, metal weld tubes, non-ferrous metal tubes, stainless steel tubes, metal plates, alloy steel, carbon steel and other metal material.

Notes:

Complied testing system standards:

YB/T4083-2000 Measurement method of comprehensive properties for eddy current flaw detection system for steel tubes

The eddy current testing method of API quality system certificate

GB/T 7735-2004 Steel Tubes Detecting Methods

Send Inquiry to This Supplier

You May Also Like

-

Laser Shaft Alignment Tool Heat Press Laser AlignmentNegotiableMOQ: 100 Pieces

-

ISO 527 Tensile Strength Tester Tensile Testing Machine for Wires and Cables High Capacity Universal Testing MachineUS$ 3000 - 10000MOQ: 1 Set

-

Hydraulic Plastic Flange Connections Cover Plugs SHF SeriesUS$ 0.22 - 0.28MOQ: 2500 Pieces

-

Impact Testing MachineUS$ 950 - 1350MOQ: 1 Piece

-

Gates 550C 550U U550 U-550 U508 U-508 Japan Unitta U-550 Belt Tension Meter New U-508 Belt Tension Meter Upgraded Version U550US$ 1 - 900MOQ: 1 Piece

-

Plastic Packaging Film Heat Seal Tester/Laboratory Heat Sealer / Five Points Heat Seal TesterUS$ 9,500 - 10,000MOQ: 1 Set

-

Diesel Fuel Injection Pump Test Bench Simulator System Control InstrumentUS$ 200 - 300MOQ: 1 Set

-

Analytical Balanace.scale ,weichengya Laboratory SupplierUS$ 10 - 35MOQ: 10 Sets

-

Smart MD-3051 Online Density Meter With 4-20mA OutputUS$ 2,380 - 2,500MOQ: 1 Unit

-

5W-300W Sun Simulator Watt Testing 30% Off / Xenon Lamp Sun Simulator Free Sent / Sun Simulator TestingUS$ 7,500 - 10,000MOQ: 1 Set