Specifications

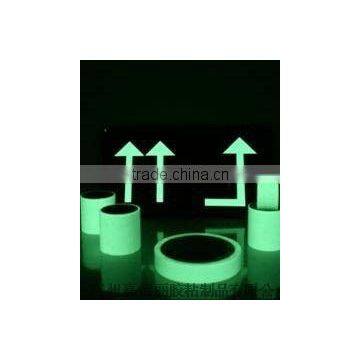

Photoluminescent Film,Self adhensive,PVC plastic

Yellow-green light color

Boat,ship, safety guidance

Silk screen printing

Brief introduction

The luminescent film is researched and produced by ourselves.Which have excellent effects of storing any visible light and glowing.After absorbing visible light for 10 to 30 minutes,they can glow in the dark for 12 hours at least. And it can be repeated any times for storing and glowing process. And they have good performance of enduring weather with non-toxic and harmless and no any radioactivity.

The luminescent film with self-adhesive can be used onto the surface of varied equipment or article,which use is the same with hard board, even more is more convenient.Such as it can be cut into many kinds of shapes or signs and put onto the place where need.Anyway it is useful and novel.For example,it is used in furniture decoration or put onto the surface of switch,telephone,handle,stationery,toy,sport article or indication in the public area, recreation ground.

Technological Index

Model | Color | Illuminating Color | Brightness mcd/m2 (No less than) | Illuminating Time (min) (0.3mcd/m2) | Specification | ||||

1min | 5min | 10min | 30min | 60min | |||||

KLM-M-O-030 | Yellow-green | Yellow-green | 1800 | 500 | 250 | 75 | 33 | 3000 | Regular 100*1000cm 30*400cm Proportional cutting enabled in the above size Thickness 0.30-0.36mm |

KLM-M-O-025 | Yellow-green | Yellow-green | 1500 | 400 | 190 | 60 | 28 | 2800 | |

KLM-M-TOS-015 | Yellow-green | Yellow-green | 500 | 190 | 90 | 24 | 9 | 1000 | |

Functions:

1. High fire retardedness by use of illuminating film made by PVC plastics

2. High capacity of saline resistant and detergent resistant

3. High capacity in cold/heat resistance

4. High mechanical functions for illuminating films

5. Strong sticking ability for illuminating films.

Usage Procedure:

1. Preferably to be applied for construction on smooth surface with the temperature of 10~40°C.

2. Cut the film into different sizes and can be directly pasted to the places like switch for decoration use.

3. Figure/ character printed on the surface.

4. Clean the surface clean before pasting. No grease mark or dust allowed on the surface.

5. The film is expandable. Be careful not to dispose it at will and recommended to keep it pressed.

6. It is prone to humidity. Preferably have it processed in environment with 40%-60% in humidity.

7. Remove the paper from back and press neatly on the surface.

8. At times, the products with different batch numbers have color differences.

9. The color films of MY, MR, MB and MG are recommended not to be used outside.

10. The film at length of 10m is likely to have junctions.

Packing and Storage

1. Packing; Curly or slice shape for handi-wrap.

2. Storage: Keep in warehouse where is ventilated, dry and cool with temperature between 15°C and30°C and relative humidity between 40% and 60%.

Send Inquiry to This Supplier

You May Also Like

-

Custom Printed 3M Road Infrared Reflective Tape With High Conspicuity for CarNegotiableMOQ: 1

-

T/C High Reflective FabricUS$ 0.2 - 0.5MOQ: 1000 Meters

-

Reflective Tape Sticker for Car Rim WheelUS$ 1 - 1MOQ: 1000 Sets

-

Outdoor Promotion Adhesive Reflective StickerUS$ 1 - 20MOQ: 1 Piece

-

Flame Retardant Reflective TapeNegotiableMOQ: 2000 Meters

-

Photoluminescent Film With Back AdhesiveUS$ 20 - 30MOQ: 1 Square Meter

-

Light Reflective Tape for ClothingUS$ 0.01 - 0.03MOQ: 3000 Meters

-

Engineering Grade Reflective Sheeting RFL 5200 Acrylic FilmNegotiableMOQ: 20 Rolls

-

Hot Sale Printable Reflective Self-Adhesive Prismatic Vinyl StickerNegotiableMOQ: 1

-

Arrow Shaped Pedestrian Safety ReflectorsNegotiableMOQ: 1