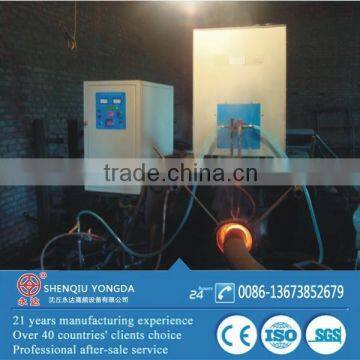

Induction Heating Tube or Pipe Annealing Furnace

Induction heating tube or pipe annealing furnace

WZP-60 pipe annelaing furnace

Technical paramters of pipe annealing furnace

Model | Input voltage | Input current | Oscillation frequency | Cooling water pressure |

WZP-40 | 320-420V | 2-40A | 15-30KHZ | 0.1MPA |

WZP-60 | 320-420V | 3-60A | 15-30KHZ | 0.2MPA |

WZP-90 | 320-420V | 4-90A | 15-30KHZ | 0.3MPA |

WZP-120 | 320-420V | 6-120A | 15-30KHZ | 0.3MPA |

WZP-160 | 320-420V | 6-160A | 15-30KHZ | 0.3MPA |

WZP-200 | 320-420V | 6-200A | 15-30KHZ | 0.3MPA |

WZP-300 | 320-420V | 6-300A | 15-30KHZ | 0.3MPA |

WZP-400 | 320-420V | 6-400A | 8-15KHZ | 0.3MPA |

WZP-500 | 320-420V | 6-500A | 8-15KHZ | 0.3MPA |

Depend on differnt specifications of your pipes, we will recommend you suitable machine power.

Applications of annealing furnace

(1) Stainless steel: stainless steel cups, stainless steel sink, stainless steel boxes, pans, pots, buckets, cutlery, forks, spoons,

(2), other types:

Metal strap flange, exhaust pipe flange, chain annealing, punching, the fans rivet heating, mine screen annealing.

Pumping gas pipe

Annealing → the workpiece is heated to a suitable temperature,with different incubation times,depending on the material and size of the workpiece , and then slow cooling (the cooling speed is the slowest),so as to make the internal organization of the metal achieve equal or at the equilibrium state, to obtain a good process properties and performance, or prepare for further hardening.

Features of pipe annealing furnace

1, small size, light weight, simple installation, easy operation.

2, high efficiency, energy saving is very clear, high-frequency equipment save 60% energy than traditional

3, secure, reliable, non-million-volt high-pressure, very safe for the operator.

4, the frequency bandwidth to meet the different parts of brazing, heat treatment, heating before forging.

5, a unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

Other work pieces annealing : lathe tool

Vacuum cup annealing

1. Reply your inquiry within 24 hours

2. Recommend suitable machine model,according to your work piece specifications and heating requirements.

3. Send detailed product parameters, photos and price.

4. Solve all the problem , such as shipping cost, shipping time,delivery time, warranty etc,what you concerned.

5. Reach an agreements, sign proforma invoice or contract.

6. Produce induction heating equipment strictly based on the PI/contract.

7. Arrange goods shipment

8.Tracking goods and help you install and operating machines.

9. Email or Call visit.

10.Provide long-terms technical support.

Send Inquiry to This Supplier

You May Also Like

-

China Plastic Melting Vacuum FurnaceNegotiableMOQ: 1

-

Gold Portable Mini Induction Melting Furnace,electric Gold Melting Furnace,gold Refining EquipmentUS$ 2,600 - 360,000MOQ: 1 Set

-

Top Quality Stainless Steel Charcoal KilnUS$ 2,000 - 3,500MOQ: 1 Set

-

1000C Compact Muffle FurnaceUS$ 400 - 700MOQ: 1 Piece

-

Foundry EquipmentUS$ 75,000 - 950,000MOQ: 1 Set

-

Annealing Temperature Sensor Stick - Industrial Supply/THERMO CRAYON/From 40 to 1070 Deg.CUS$ 1,000 - 2,000MOQ: 5 Pieces

-

SELON SED-8S2 INFRARED INTELLIGENT DIGEST STOVE, RESISTANCE TO ACID ALKALI SPECIAL HOSE, USA MICROPUMPUS$ 1,225 - 1,307MOQ: 1 Set

-

Coal Combustion Hot Air Furnace Used in Grain ProcessingUS$ 230,000 - 890,000MOQ: 1 Set

-

Our Equipment 80 MT Ladle Refining Furnace for Secondary SteelmakingUS$ 1,500 - 6,000MOQ: 1 Metric Ton

-

Magnesium Carbonate Pyrolysis FurnaceNegotiableMOQ: 1