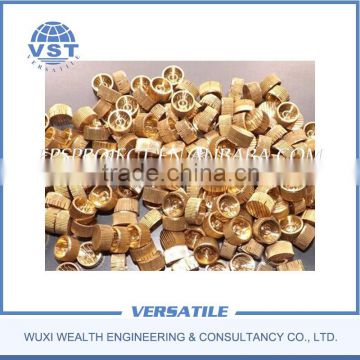

1.Pictures of steel steam jet

2.Description of steel steam jet

Unique product made by Powder Metallurgy Process

Sintered Vent is produced by applying sintering process of powder metals and has many paralleled, straight micro pores that allow air/gas purge.

It is also called air vent or gas vent and used as gas purging vent during aluminum casting and resin molding. If a certain level of air and/or gas, which comes from raw materials, remains inside the cavity at the time of injection of melted resin or casting of aluminum alloy under low pressure, it defects the finished products. Our vent helps purging those air and gas during molding process.

3.Advantage of steel steam jet

steam core vent is available in various shapes such as drilled, slotted and blanks etc. The Core Vent is provided with slot and hole in the diameters 6, 8, 10, 12, 14, 15, 16, 18, 20, 22, 25, 30, 40 mm etc. The Core Vent is made using quality grade raw material which ensures durability of use along with long lasting trouble free service. Brass Core Vent with Slot/ Hole is application specific in design and accurate in dimension. .

4.Application of steel steam jet

1. Degasing for low-pressure casting or plastic molding

2. Fluid damper or silencer

3. Fluid jet nozzle

4. Pivot ball bearing or bearing for a sliding section

5. Heat exchanger

6. Fluid catalyst

7. Heat sink material(high temperature conduction, low temperature inflation)

8. Electric contacts and electrode materials

9. Beam screen(image mask)

10. Stabilizer for superconductive material

5.More Products for You to Choose

MOQ | 1 Set |

Payment Method | L/C, T/T |

Port | Shanghai/Ningbo |

Delivery | 30 days after received deposit or LC |

Supplier Capacity | 30 units per month |

Packing | standard exporting package . |

1.About Us

1)Wuxi Wealth Engineering & Consultancy Co., Ltd. specially deal with all kinds of EPS machines and give

consultancy service to those clients who plan to set up new EPS factory. Working in EPS machine field for

over 12 years, and having helped hundreds of clients to build new EPS factory, we are very confident and

competent to offer you complete turn-key projects for EPS industry.

2)We are associated with several EPS machine manufacturers in China, so we can easily match different

clients’ request. Sitting in the manufacturing base of EPS machines, we can regularly follow up machine

production and inspect machine quality, We follow the principle of “service first, quality first” to develop our

business. Our team is constantly making efforts to answer clients’ request within shortest time, and our

professional technicians always give you fast response for your questions and complaints. We pay whole

life responsibilty for the products we sell.

3)We sincerely hope establishing long and friendly business relationship with clients from all over the world.

2.Sample Room

3.Exhibition

4.Engineering

5.Customers

6.Our Team

Send Inquiry to This Supplier

You May Also Like

-

Agriculture Using Plastic Shape Moulds Heart, Star, Square, Flower Shape Cucumber and Fruit MouldNegotiableMOQ: 500 Pieces

-

GYC Small 300-600kg/h Toilet Soap Making Machine From OilNegotiableMOQ: 1

-

OEM Customized Molded Enclosure Injection Plastic Molding For ElectronicsNegotiableMOQ: 1

-

Vanity TopNegotiableMOQ: 1

-

Brand New Waterproof Pvc Flooring With Great PriceUS$ 80 - 117MOQ: 1 Piece

-

Mould For ScrubberNegotiableMOQ: 1

-

Fully Automatic Cotton Swab Making Machine With Packing And Drying | Cotton Bud Maker Machine Wooden Cotton Swab Making MachineUS$ 23,500 - 23,500MOQ: 1 Set

-

Plastic Motor Part Mould, Laptop Plastic Parts Mould Such as Side Body Motorcycle, Fairying Covers for Motorcycle!US$ 0.1 - 2MOQ: 5000 Pieces

-

6.35mm Adjustable M2-M10 Carbon Steel Body Die Holder Wrench Set for Power ToolsUS$ 1 - 30MOQ: 640 Pieces

-

2016 Hot Selling Concrete Plastic Paving Mould for Interlock Tile MakingUS$ 1 - 5MOQ: 500 Pieces