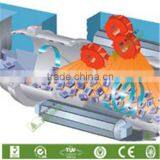

HESONG company offers two distinct categories of Tumblast or tumble blast machine. Batch Type Tumblast machines process parts batch by batch, in a stop-start operation, and Continuous Tumblast machines pass the parts through the machine and onto the next process in the operation.

Continuous Tumblast machines (CT) treat the same parts but are situated within either an automated process or a continuous production line. The advantages of this being high performance rates, less or no human contact with parts, and a more speedy, complete process for the parts.

The through-feed blast cleaning process offers a number of distinct advantages and ensures efficient and cost effective blast cleaning. Continuous shot blast machines automate production sequences and improve the work environment.

Benefits

• High cleaning capacity, short blasting times

• Careful arrangement of blast wheels on the machine results in optimum utilisation of the abrasive energy

• Full exposure of all workpiece surfaces to the blast stream

• Automatic material flow control, optimal filling degree of barrel and the automatic adaptation of abrasive throughput result in the best possible cleaning effect and minimal wear on machine components and abrasive

• Blast cleaning performance is maintained at a consistently high level, regardless of fluctuations in production rates

• Easy maintenance set up

• Integration into existing production lines

• Leading technology, outstanding experience

• Adaptable inlet, outlet and blastroom set up to meet different workpiece configurations

• Adaptable to treat tumble-proof fragile castings

The following applications can be undertaken:

• Desanding and decoring of castings

• Descaling of castings, forgings and heat treated parts

• Shot peening (without process security)

• Deburring of plastic and rubber parts

Applications

• Removing sand and cores from castings

• Descaling castings and forgings

• Handling mixed and single product runs

• Cleaning clusters

1. Our company has passed "CE", "ISO9001" and bureau veritas certification .

2. 50 years experience with 20 professional engineers in our Qingdao Foundry Machine Co.,Ltd.

3. So many kinds of foundry machinery ---100 kinds of shot / sand blasting machines and 80 kinds of casting machines.

4. Considerate after-sale service , Technial Assistance and provide installing ,debugging and training on site.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3). Q: How does your factory do regarding quality control?

A: Quality is priority. MACTEC People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. MACTEC is ALIBAB’s Gold supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers.

In order to give you the suitable machine , pls provide below message for us :

1. What is your workpiece and the material and the shape ?

2.The Max. Length/Width/Height of the workpiece and the MAX./MIN.weight of your workpiece ?

3.The productity you need to blasting the workpiece ( how many T or piece per day or per month?)

4. The power supply you need( Our China :380V, 3PH, 50HZ)

5. Better to send us the workpiece photo or drawing.

Welcome to contact us or visit our company.

Send Inquiry to This Supplier

You May Also Like

-

Belt Shot Blasting Cleaning EquipmentUS$ 4,000 - 10,000MOQ: 1 Set

-

Portable SandblasterUS$ 195 - 220MOQ: 300 Pieces

-

Cleaning of Road MachineUS$ 340 - 350MOQ: 20 Pieces

-

Rotary Drum Shot Blasting MachineUS$ 2000 - 20000MOQ: 1 Unit

-

Q32 Apron Type Shot Blasting MachineNegotiableMOQ: 1 Set

-

Tumble Belt Shot Blasting Machine to India / Q326 / 200kg / Crawler Type / Rubber BeltUS$ 5500MOQ: 1 Set

-

Perfect Laser Industrial 100/200W Metal Rust Laser Derusting Cleaning Machine With Smoke CollectorUS$ 10000 - 12000MOQ: 1 Set

-

Hanger Shot Blasting Machine for Brake Disk Surface CleaningUS$ 2000 - 20000MOQ: 1 Set

-

Supports Multi-hook Customization of Pumingwei Hook-type Shot Blasting Machine Surface Metal Rust Removal EquipmentNegotiableMOQ: 1 Piece

-

Tumble Rubber Belt Shot Blasting Machine for Foundry Plant Crawler Shot BlasterUS$ 2000 - 6000MOQ: 1 Piece