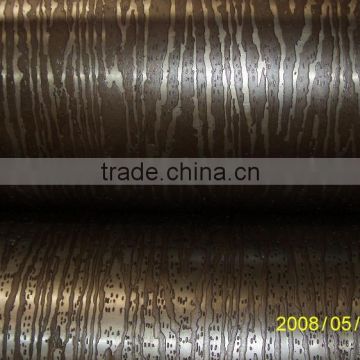

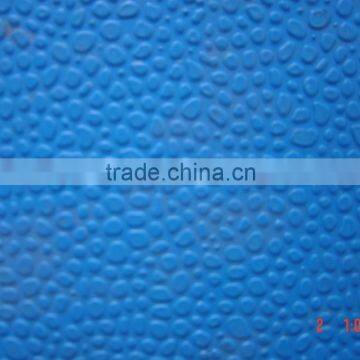

Metal sheet embossing machine

We are a professional manufacturer and exporter of Steel Roll Forming Machine, and corrugated steel sheet, sandwich panel and steel coils in Hangzhou with convinent transportantion: about 10 kms away from Hanzhou International Airport,180km away from Shanghai and Ningbo port.

Our workshop covers more than 10,000 square meters and about 150 technical staffs work in our factory. We have rich technical force,high-level managerial team, advanced production facilities, strong production capacity and strict quality control system.

What we value is reputation and service, what we sell is quality and technology.

This model is suitable for guard door, steel structure, moreover rigidity of the panel will strength more after embossing. Pressed flower of embossing press machine can be designed according to customers' request.

Main parameters:

| Raw material | colored steel sheet or galvanized steel sheet |

| Thickness of steel | 0.2-0.6mm |

| Width of steel | 600-1250mm |

| Run direction | both direction |

| Working speed | 10-15m/min |

| Motor power | 11kw |

| Machine dimension | 1700*1300*1500 |

| Total weight | about 3 tons |

| Roller material | high grade 9Cr2Mo, with 60-63HRC quenched treatment |

| Width of the machine | 1300mm (depend on final design) |

| Voltage | 380V 3phase 60HZ or at buyer's requirement |

| Roller diameter | 280mm(depend on final design) |

Product's machine

WHY CHOOES OUR COMPANY

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. AOFA is ALIBAB’s Gold supplier with BV assessment and CE certificate.

4) Q:What can you do if the machine broken?

A: Our machine's warranty period is one year, if the broken parts can't repair, we can send the new parts to replace the broken part freely, but you need to pay the express cost. If after warranty period, we can through negotiation to solve the problems, and we also can supply the technical support for the whole life of the equipment.

5) Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

6) Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Send Inquiry to This Supplier

You May Also Like

-

Hydraulic Baler for CansUS$ 3000MOQ: 1 Unit

-

High Adhesion Uniform Coating Fluidized Bed Dip Powder Coating Equipment Versatile for Refrigerator Shelves and Metal PartsUS$ 2000 - 40000MOQ: 1 Set

-

Replaceable Knives Wood Chipper Moveable Type Chips Ready for Compost or BoilersNegotiableMOQ: 1 Set

-

Multifunctional Hydraulic Baler/hydraulic Briquetting Machine Manufacturing PlantUS$ 5500MOQ: 1 Unit

-

High Efficiency Energy Saving Fluidized Bed Dip Powder Coating Equipment Eco Friendly for Refrigerator ShelvesUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Semi Automatic Manual Fluidized Bed Dip Powder Coating Equipment Customizable for Refrigerator ShelvesUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

Wood Chipper Price Tree Branches Reduce Debris by 80% With Precision BladesNegotiableMOQ: 1 Set

-

Drum Wood Chipper Manufacturer Quality Ideal for Forestry, FarmsNegotiableMOQ: 1 Set