Features:

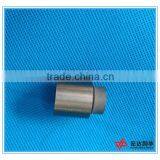

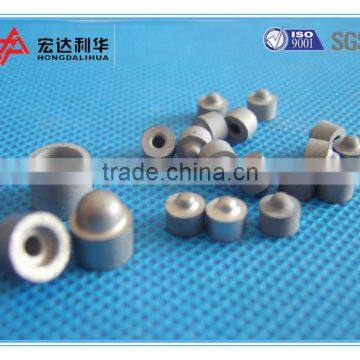

•Model NO.: Carbide Nozzles/Spraying

• Cer: ISO9001 SGS

• Appearance: Polishing, Sintering

• Specification: According to Your Request, ISO9001 SGS

• Business Type: Manufacturer

• Trademark: LIHUA

• Place of Origin: Zhuzhou China (Mainland)

• Name: Tungsten Carbide Nozzles

• Process Engineer: Adopt Advanced Technology

• Performance: Excellent Wear Resistance

• Advantage: Over 20 Years Experiences in This Line

• Origin: Zhuzhou, China (Mainland)

Features:

1.With Submicro grain size

2.High wear resistance and toughness

3.High combination abilities

4.Precision Ground and polished

5.With HIP sintering

Features:

Slurry nozzles or mud nozzles are widely applied in the field of oil industry.As an essential part of oil and gas drilling.,mud nozzles play a key role to flow velocity and pressure. It's important that nozzles fit well and are arranged for maximum flow benefits. Zhengtong's mud nozzles are manufactured in a variety of styles, including threaded, standard, and extended, so they match all bit designs.

Attention

1, Carbide nozzles are tools and should be looked after and protected from damage at work site.

2, Boron carbide nozzles are the most commonly used nozzles in the sandblasting / abrasive blast cleaning industry. They are tough and are best suited for use in harsh work site conditions. Tungsten carbide nozzles are economical and work well with most abrasives.

Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Contact:

Foreign Sales Representative: Julia

Mobile: +86 18273297052

Website:

Factory Add: Tower A, 6th Building, Block C, Auto parts park, Taiyuan zone, Zhuzhou city, Hunan province, China

Postcode: 412000

Zhuzhou Lihua Cemented Carbide Co., Ltd was established in 1990, integrated with production, research, development, sales, and technical service. Full of rich experience in the field of the tungsten Carbide, Lihua performs excellence.

Our company mainly produce such products as carbide rod& tubing, carbide strips &plates, carbide bars, carbide saw blade, carbide end mills, carbide drill bits, Carbide welding inserts, carbide CNC inserts, carbide woodworking tools, tungsten carbide powder, some non-standard tungsten carbide products and different other various type of the tungsten carbide products etc.

We have independent developed YS series of tungsten carbide grade that belongs to the micro hole grain of tungsten carbide, with good abrasion resistance, strong impact resistance, affinity resistance, good heat conduction performance and so on.

Lihua is committed to the principle of "customer first, fast delivery and good after-sale service ". If you have any questions and any demand of tungsten carbide, please contact us without any hesitation. We guarantee not only qualified products, but also designing, prompt delivery, the most competitive prices and all solutions.

Send Inquiry to This Supplier

You May Also Like

-

Customized Bimetal Hardfacing Chromium Carbide Overlay Wear Resistant PipeNegotiableMOQ: 1 Square Meter

-

YG6YG8electrical Wire Drawing Die Wire Moulding Tungsten Carbide Wire Drawing DiesNegotiableMOQ: 1

-

Apv Tungsten Carbide SleevesUS$ 0.5 - 20MOQ: 20 Pieces

-

UHMWPE Black Leg Pads for Heavy Machinery, Wear-resistant, Anti-slip, and High Load-bearingNegotiableMOQ: 1 Piece

-

Grinding Rod, Steel Grinding Bar, Grinding Bar, Grinding Ball, Forged Steel Grinding Ball DIA20-150MMNegotiableMOQ: 25 Metric Tons

-

Ground Cemented Tungsten Carbide Rod Tungsten BarUS$ 10 - 20MOQ: 50 Pieces

-

Crushed Tungsten Carbide GritsUS$ 43 - 46MOQ: 10 Kilograms

-

Customized Cemented Carbide Nozzle Valve Disk Shaft Inserts Blanks Saw Blades Flow Orifice Scraper Strips RodsUS$ 10 - 500MOQ: 1 Set

-

CD-650 High Precision Tungsten Carbide Blank for Carbide Punches Die InsertsUS$ 50 - 500MOQ: 2 Pieces

-

YG25/GT55 Tungtsen Carbide Punching Dies for BoltUS$ 30 - 40MOQ: 1 Kilogram