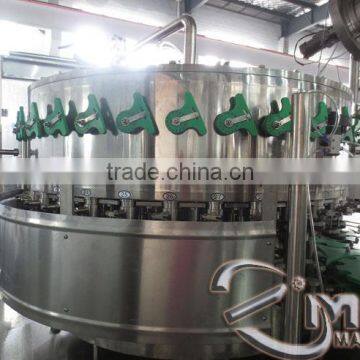

MIC-32-32-6 Micmachinery Top Quality Monoblock Small Beer Bottle Filling Machine Beer Liquid Bottle Filling Machine With CE

MIC-32-32-6 Micmachinery top quality monoblock small beer bottle filling machine beer liquid bottle filling machine 8000-10000bph with CE

Video link:/watch?v=_kWjMK9v5Uo

We are manufacturer for can filling seaming machine and glass bottle filling capping machine, steady machine which can reach Germany standard, hope you can come to see us.

Other type machine:

Model No. | XGF12-8-1 | XGF12-12-1 | XGF18-18-1 | XGF18-18-6 |

Rinsing heads | 12 | 12 | 18 | 18 |

Filling heads | 8 | 12 | 18 | 18 |

Capping heads | 1 | 1 | 1 | 6 |

Production capacity | 1000BPH | 2000BPH | 2500BPH | 4000BPH |

Model No. | XGF24-24-6 | XGF32-24-6 | XGF32-32-6 | XGF72-72-8 |

Rinsing heads | 24 | 32 | 32 | 72 |

Filling heads | 24 | 24 | 32 | 72 |

Capping heads | 6 | 6 | 6 | 8 |

Production capacity | 5000BPH | 8000BPH | 10000BPH | 36000BPH |

Product Description:

1) Compact conformation, good shape, cozy operation, excellent automaticity and poor labor intensity.

2) Only exchanging "star wheel", "feeding screw" and "arc guide plate" is needed while exchanging model of bottle.

3) The all parts directly contacted with material are all adopted with food stage stainless steel without dead angle, So they can be cleaned easily.

4) Adopting advanced valve to control the inlet flow rate of liquid. It can keep the slight turbulence of liquid level in the solution barrel and ensure the accuracy in filling.

5) Closing feeding valve automatically while no bottle on machine avoid the loss of aqueous feet. Filling automatically is with a high speed and the control of liquid level is accurate.

6) The magnetic-constant-torque device is adopted in capping head to ensure the high capping quality without damage.

7) Adopting efficient cap settling system which carried perfect cap feeding and protection device.

8) It is adopted spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel. And to adjust the input height is not necessary for exchanging model of bottle.

9) carried the perfect protection system to overload; it can be used to protect facilities and operators efficiently.

10) Because of applying touch screen for operation, it is possible to realize man-machine conversation whereas the status of device running is clear at a glance.

11) The primary electric components such as touch screenPLCtransducer etc. are all adopted with well known import products.

Rinser

1. The rotary wheel is a fully stainless steel welded structure.

2. The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

3. The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

4. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

5. The rinser is driven by driving system positioned inside machine frame via gear transmission.

6. Transfer starwheel

7. Made of stainless steel of superior quality.

8. Equipped with bottle jam protection device.

Filler

1. Rotary wheel fully made of stainless steel SUS 304.

2. Gravity filling method.

3. Filling valves are made of SUS316L.

4. Filling valves are reasonably structured with accurate filling.

5. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

6. Level of cylinder is controlled with float-ball.

7. Filler is driven through gears inside the machine frame.

8. Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck.

Capper

Capper is the machine with highest precision, influence very much with the stability and reliability of the filling monoblock. Our capper features as follows:

1. Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

2. Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

3. The capper is equipped with inlet bottle detection switch.

4. Centrifugal way of cap arranging is adopted to reduce damage of caps.

5. A cap inspecting system is applied to control on-off of elevator.

Packaging & Shipping:

1.Small beer bottle filling machine beer liquid bottle filling machine

2.Export wooden case

3.One set in one case

4.Film wrapped

5.Wooden case size

Company Information:

FAQ

For Automatic glass bottle filling sealing machine question:

First of all, Before we operate Automatic glass bottle filling sealing machine, to clearly understand the instructions clearly Automatic glass bottle filling sealing machine, first read through the instructions again, adjust and use the familiar Automatic glass bottle filling sealing machine operating time must be in strict accordance with the instructions to Automatic glass bottle filling sealing machine instructions , pay attention to details of the problem , certainly the details determine success or failure

Secondly, In accordance with the instructions on the machine for regular repair and maintenance of the Automatic glass bottle filling sealing machine fuselage Oil it , so Automatic glass bottle filling sealing machine body as far as possible to protect the reservoir, so that the air can be isolated to avoid Automatic glass bottle filling sealing machine rusty , well protected Automatic glass bottle filling sealing machine body, and this is a way to extend the life of the 2 in1 filling machine .

Once again, We have to pay attention to hot stand -sealing cloth for cleaning, not retained foreign body in the above, to ensure clean Automatic glass bottle filling sealing machine try to avoid the amount of material for a long time into the mouth of the left cause corrosion.

Fourth, We should always check the machine to see contacts at various parts of the machine is good, important to ensure safe use of electricity, no electricity properly to prevent harm.

Fifth, If found faulty , we have to turn off the power , when necessary, by pressing the emergency stop button , and then deflated lift cover, and then close the voltage , check the reason , and troubleshooting.

Our Services:

According to customer’s requirement, we will offer our technician for oversea to install and adjust small beer bottle filling machine beer liquid bottle filling machine service.

We can also provide our Sales as translator to your site help the installation and Training.

Only to provide the local transportation, accommodation, air tickets (round trip) for Sales will be fine.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Spice Powder Grinding Machines Salt and Peeper Grinder Nut Grinder Machine for Food ProcessingUS$ 620 - 1060MOQ: 1 Set

-

Semi Automatic FIBC Filling Systems Manual Bag Breaker ,fibc LoaderUS$ 1 - 48000MOQ: 1 Set

-

Auto Bottled Water Filling And Capping MachineNegotiableMOQ: 1 Set

-

GNEYOND Protein Powder Filling and Seaming Line Milk Powder Tin Can Filling Sealing MachineNegotiableMOQ: 1 Set

-

Pyramid Tea Bag Packing Machine|Tea Sachet Packaging MachineNegotiableMOQ: 1 Set

-

China Small Beverage Bottle Wrapping Machine /juice Bottle Packing Machine/shrink Packing MachineUS$ 4,000 - 10,000MOQ: 1 Set

-

Flexible Permanent Neodymium Ball Magnets Colorful Magnetic Bucky BallsNegotiableMOQ: 1 Set

-

LCS-10/50LY Double-auger, With Weighing Bucket, Automatic Weighing Packing MachineUS$ 1 - 500MOQ: 1 Set

-

ALGFM-1 Popular Automatic Packaging Machines for GrainUS$ 1 - 6,000MOQ: 1 Set

-

Factory Price Bottled Tomato Paste Filling MachineNegotiableMOQ: 1 Set