1 | subject

| |

form

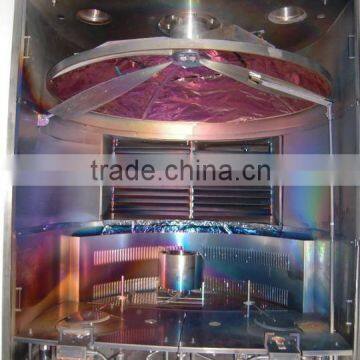

| Box type, vertical before the door, evaporation chamber and air suction chamber, with close insurance open; Between host and electric control cabinet installed metal trough (mainly connecting cable, wire, water softening tube and soft tracheal are in metal trough), and from the host and electric control ark party all. Water, electricity, gas and have fault automatic alarm and protect system; The buzzer alarm.

| |

2. Vacuum cavity |

Inner chamber size for 1100 mm (diameter) x H1350mm (high)

| |

3 Vacuum chamber door

| Adopts 304 stainless steel materials, Vacuum chamber door set observation window 3, the position in a central, around the mid-lower each one, and install glass and manual rotation of protection lens, stainless steel damper with interior.

| |

4. Host skeleton

|

The steel manufacturing, skeleton front have lock door. Both sides have belt shutter can remove fixed side plate.

| |

5.Water cooling system

| Host, the jellyfish tube stainless steel tube, pipe pass in and out are equipped with manual ball valve, the main cooling parts are separate water supply cooling | |

6. Control electric tank

|

The adoption and tank mode, including instrument installation cabinet 19 inch international standard control electric cabinet, another electrical components installed cabinet for QianHouMen big plate structure.

| |

7. | With two fixed damper (fixed)

| |

2 |

Vacuum system

| |

1.Ultimate vacuum

| 3×10-4 Pa≤4 hours (light, cold, clean space)

| |

2.Recovery vacuum time

| Atmospheric to 4×10-3Pa≤15min (light, cold, clean space)

| |

3. The vacuum | In the vacuum chamber to achieve ultimate vacuum off the high vacuum valve 1 hours later, vacuum chamber vacuum ≤5×10-1Pa

| |

4. Vacuum system configuration

| 1) main pump: K630 type diffusion pump (shenyang vacuum) 2 table; 2) backing pump 2 x - 150 type plunger pump (or central 70 pump) 1 300 rose, pump 1 2 x - 30 mechanical pump 3) equipped with anti turbulence device (can reduce vacuum fixed row of atmospheric turbulence on the influence of work); 4) diffusion pump and high between valve with a set of compound water well.

| |

5. Vacuum system measurement

| 1) match ZDF - Ⅲ type composite vacuum gauge 1 set of 2) high vacuum ionization gauge installed in vacuum box air suction chamber lateral near the gun side; 3) resistance gauge a group of installed in vacuum box air suction chamber top, another group of installed in diffusion pump backing line ; 4) each measuring gauge tube vertical installed by, glass vacuum gauge tube are metal protection screen;

| |

6 Vacuum system operation |

A manual and procedures to be automatic two modes

| |

7. Test method | According to the GB11164 vacuum coating machine general technical conditions execution

|

We can make design the dimension of the vacuum chamber according to your requirement. We can also design and configure the vacuum unit and electric controlling system according to your requirement.

Send Inquiry to This Supplier

You May Also Like

-

Electrostatic Paint Spray GunUS$ 200 - 500MOQ: 5 Pieces

-

Touch Screen Desktop Vessel Dip Coater With Variable Speed Multi Station ProgrammableUS$ 1,700 - 3,000MOQ: 1 Set

-

Coating LineUS$ 1,000 - 100,000MOQ: 1 Set

-

Aluminum CNC Milling Services For Auto Doors , Appliances , Safety IndustryNegotiableMOQ: 1 Piece

-

Stainless Steel Custom Fasteners Screws For Auto Vehicle Fuel SystemNegotiableMOQ: 1 Piece

-

Professional High Speed CNC Laser Cutting Machine , 1000W Laser Cutter EquipmentUS$ 30000 - 200000MOQ: 1 Piece

-

T Shaped Aluminum Extrusion Profiles Products For Commercial Building / FurnitureNegotiableMOQ: 1 Piece

-

Stainless Steel Sheet PVD Coating (Vacuum Plating) EquipmentUS$ 8 - 10MOQ: 1 Piece

-

Transition Double Rows Connection Bolt Couplering With Locked-nuts 12MM - 40MMNegotiableMOQ: 1 Piece

-

Loudspeaker Nd-Fe-b / Neodymium Disc Magnets With Epoxy / Parylene CoatingUS$ 0.01 - 2MOQ: 1 Piece