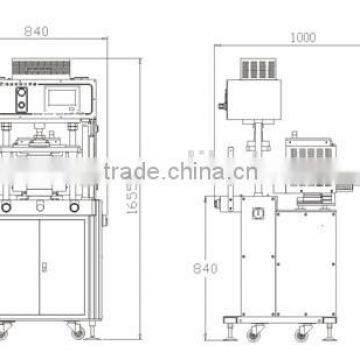

LPMS Low Pressure Molding Injection Molding Machine Over Mold Injection Molding Machine Over Mold Injection Molding Equipment

JX-350 low pressure molding machine with Single Station design low pressure injection molding machine low pressure injection molding equipment low pressure molding machine over mold low pressure over mold LPMS low pressure molding system

[Machine features]

1.Single station vertical hot runner injection system. especially on the left and right parallel continuous wire outlet mold design is more reasonable and reliable.

2.Console and sol system uses split layout,flexible use..

3.Gum pump and sol cylinders integrated device. Compact structure, stable performance.

4.Mold using gas-liquid pressurized cylinder, Mold clamping force is greater,suit tor mass production of large area, large glue quantity product injection.

5.Gum pump and sol cylinders integrated device .compact structure,stable performance.

6.Glue injection time shorten than ordinary machine, improve production efficiency, meet the high-volume production needs.

7.Computer touch-screen display, with multi-language PLC control system.

8.Injection pressure adjustable, DELTA temperature control module, accurate monitoring of temperature conditions.

9.The hands switch clamping and safety grating, emergency stop switch, to ensure safe operation.

10.The mold is convenient to replace, workbench built product ejection device, convenient to extract products.

11.Dual cylinders is optional glue injection is more stable, higher production efficiency.

12.According to human engineering machine pedal design convenient operation.

[Specifications]

Plastic machinery | JX-350 |

Size(mm)Machine(kg) | 970x890x2050 (400Kg) |

WorkStation Height(mm) | 1020 |

Plant View(mm) | About/1730x1400 |

Packing(mm)Size(kg) | 1050x1000x2100 (450Kg) |

Melting Tank | (5Liter)x1 |

Each station Gun Tip Qty | 2or4 depends on part design) |

Gun & Tip Angle | (36.4°60°90° |

Heated Hose | JX-ZH-16-C×1 |

Electricity | 200-240VAC/1Phase/50 or 60Hz |

Temperature Control Zones | 5 |

Temperature Range | 70°-260°℃ |

Max.Power(Kw) | 4kw |

Working pressure(Mpa) | 0.5(Mpa)~0.8(Mpa) |

Air Consumption | 0.1m3/min |

Clamping Device | (Air Over Oil) |

Clamping Force | (Max.)10 Tons |

Clamping Stroke(mm) | 150 |

Control System | /touch screen |

Standard Mold Set Size(mm) | 250x150x303(75Kg) |

Max.Mold Set Size(mm) | 300x200x303 |

Max. Part Size(mm) | 100x90x18 |

Send Inquiry to This Supplier

You May Also Like

-

7 Shape Battery Pcb Welding Systems , Welder for Battery Protection Plate Battery Pcb Welding AutomationUS$ 3500.00 - 3500.00MOQ: 1 Set

-

Lithium Battery Automatic Packing Machine , Battery Bagging Machine AutomationUS$ 3,000 - 5,000MOQ: 1 Set

-

Promotion Battery Protection Board Welder ,battery Protection Board Welder ChinaUS$ 3000.00 - 3000.00MOQ: 1 Set

-

Battery PCB Welding Processing Solution ,7 Shape Automatic Welding for Battery PcbUS$ 3500.00 - 3500.00MOQ: 1 Set

-

Lithium Battery Pcb Welder Automating Welding Machine for Battery Pcb 1 Shape Battery Pcb WelderUS$ 3000.00 - 3000.00MOQ: 1 Set

-

7 Shape Battery Protection Board Welding Systems , Welder for Battery Protection PlateUS$ 3500.00 - 3500.00MOQ: 1 Set

-

Battery Bagging Machine Automation Bagger Machine for Lithium Battery Battery Bagger MachineUS$ 3,000 - 5,000MOQ: 1 Set

-

Mobile Battery Automatic Packing System , Lithium Battery Automatic Packing SolutionUS$ 3,000 - 5,000MOQ: 1 Set

-

Automating Label Machine Battery Label Solution Lithium Battery Labeling MachineUS$ 4,000 - 6,000MOQ: 1 Set

-

Battery Automatic Packing Solution ,automatic Packing Machine for Lithium BatteryUS$ 3,000 - 5,000MOQ: 1 Set