JX-2200 / Side Duplex Split Plastic Moulding Machine JX-2200

JX-2200 / Side Duplex Split Plastic Moulding Machine JX-2200 work with double side injection moulding system.This plastic moulding machine can improve the production efficient with two moulding stations.In other words,this machine need to two staff to work together.

[Features]

1, duplex Side dispensing systems, duplex table, high-capacity plastic tank is designed to give maximum productivity for manufacturers. Console and sol system uses split layout.

2, plastic pump with plastic tank integrated devices. Compact structure, stable performance.

3,7-inch touch-screen computer interface, real-time display of machine operation and the functional parameters.

4, plastic injection pressure adjustable, DELTA temperature control module, precise monitoring of temperature conditions.

5, the larger the mold table given more space to provide more flexible.

6, clamping his hands and safety grating switch, emergency stop switch, to ensure safe operation.

7, optional Shuangjiao cylinders, dispensing more stable, more productive, more widely used.

8, the machine in accordance with ergonomic pedals designed to facilitate the operation of production.

[Specifications]

Plastic machinery | JX-2200 |

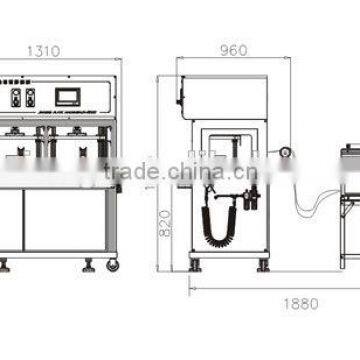

Size(mm)Machine(kg) | 1310x960x1650 (540kg) |

WorkStation Height(mm) | 850 |

Plant View(mm) | 1700x1300 |

Packing(mm)Size(kg) | 1450x1060x1700 (590kg) |

Melting Tank | (5Liter)×1 or2 optional |

Gun & Tip Angle | (36.4°60°.90°)optional |

Heated Hose | JX-ZH-12-C×2 |

Electricity | 200-240VAC/1Phase/50 or 60Hz |

Temperature Control Zones | 5 |

Temperature Range | 70℃- 260℃ |

Max.Power(Kw) | 6 |

Working pressure(Mpa) | 0.5(Mpa)~0.8(Mpa) |

Air Consumption | 0.18m3/min |

Clamping Device | Pneumatic |

Clamping Force | Max.1.2 Tons |

Clamping Stroke(mm) | 125mm or 150mm option |

Control System | touch screen |

Standard Mold Set Size(mm) | 230×120×150 (25kg) |

Max.Mold Set Size(mm) | 300×200×150 |

1.Q: What is the product ?

A: It is a plastic injection machine,can encapsulate and protect the electronic components.

2. Q: What about the quality guarantee and after-sale service ?

A: we prrovide one year quality guarantee , full time after-sale service .

3.Q: we want to open an automating system for 18650 26650 battery , how it can do that ?

A: Yes , we can provide you the battery automating system and solution .

If you want to know more,please contact me:

Name: Wendy Xie

Tel/Whatsapp: +8615623046687

Wechat: xqw1117

QQ: 2066875151

Send Inquiry to This Supplier

You May Also Like

-

Plastic Injection Molding Machine Single Station Vertical Lntengrated Machine Top Type Glue Injection MachineUS$ 1,000 - 7,000MOQ: 1 Set

-

Best Price LPMS Plastic Low Pressure Injection for LED Light PCBA Sensor Battery Plastic Low Pressure InjectionUS$ 6000.00 - 6000.00MOQ: 1 Set

-

JX-1800H Low Price Single Station With Touch-PLC Screem Plastic Low Pressure Molding MachineUS$ 3077.00 - 3846.00MOQ: 1 Set

-

Best Price India Battery Making Machine Low Pressure Plastic Inject Injection Molding Moulding Machine Price Equipment IndiaUS$ 3077.00 - 3846.00MOQ: 1 Set

-

Lowest Price Top Technology Multifunctional Low Pressure Plastic Injection Moulding MachineUS$ 3077.00 - 3846.00MOQ: 1 Set

-

Integrated Vertical Low Pressure Injection Plastic Injection Molding Machine JX-1800HUS$ 3077.00 - 3846.00MOQ: 1 Set

-

LPMS Low Pressure Molding System Low Pressure Plastic Injection Molding Machine Connectors Grommets Switches BatteriesUS$ 6000.00 - 6000.00MOQ: 1 Set

-

LPMS Low Pressure Molding System Machine Low Pressure Technology Low Pressure Injection Moulding ProcessUS$ 6,000 - 7,000MOQ: 1 Set

-

LPMS Low Pressure Molding System Plastic Injection Molding Machine Top Type Glue Injection MachineUS$ 1,000 - 7,000MOQ: 1 Set

-

Injection Molding Machine Injection Molding Equipment With Low Pressure Injection Molding DesignUS$ 2,500 - 6,800MOQ: 1 Set