plastic corrugated plate making machine

plastic corrugated plate making machine

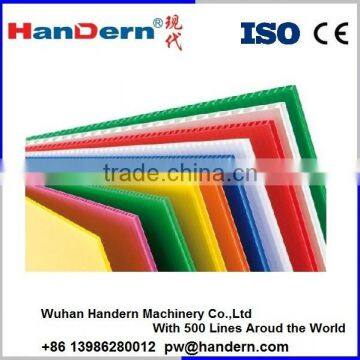

PC hollow profile production plant is to manufacture PP PE PC hollow sheet, which have many advantages than cardboard.

1) Light Weight

2) Innocuous, non-taste

3) Waterproof, moisture resistance

4) Strong impact resistance

5) Ageing resistant

6) Corrosion resistant

7) Heat and sound insulation

8) Recyclingenvironment-friendly

plastic corrugated plate making machine

1) Packing Material: Instead of the traditional packing material such as corrugated paper, wood board, etc.

2) Turnover box: the container of electric parts, food, drink.

3) Advertising Board: advertising board, show board, brand mark, light box board, etc.

4) Industry Uses: Protection board, padding board, luggage carrier, separating board, baseboard, cross board for all things

5)Construction Board: Partition, protection board of wall, ceiling board

Number

| Item | Unit | Quantity |

1

| Extruder with single screw | set | 1 |

2

| Screen Changer | set | 1 |

3

| Die | set | 1 |

4

| Vaccum Calibrator | set | 1 |

5

| First haul-off unit | set | 1 |

6

| Drying oven | set | 1 |

7

| Cooling Device | set | 1 |

8

| Second haul-off unit | set | 1 |

9

| Cutting device | set | 1 |

10

| Electrical control Cabinet | set | 1 |

11

| Stacker Unit | set | 1 |

12

| Screw feeder | set | 1 |

Specifications of plastic corrugated plate making machine

Machine type | 1400 | 1800 | 2300 | 2700 |

Max sheet width(mm) | 1250 | 1650 | 2150 | 2550 |

Sheet thickness(mm) | 2-6 6-12 15-20 | 2-6 6-12 15-20 | 2-6 6-12 | 2-6 6-12 |

Line Speed(m/min) | 1-6 2-10 | 1-6 2-10 | 1-6 2-10 | 1-6 2-10 |

Max output(kg/h) | 180-260 | 220-350 | 320-450 | 360-500 |

Motor power(kw) | 55-90 | 75-110 | 90-132 | 110-160 |

Screw Model | SJ105/36 | SJ110/36 | SJ120/36 | SJ135/36 SJ150/36 |

Advantages of plastic corrugated plate making machine

New design screw extruder: line with market demands and adapt to many kinds of raw materials, with the advantages of good plasticizing, uniform distribution and high output.

Hydraulic pressure screen exchange: short course of changing screen and stable operation of operators

Molding die: with high quality alloy steel lips and restrict bars to ensure even pressure and uniform thickness of the finished sheet.

Vacuum Calibrator: convective heat with array interleaved to ensure high precise calibration. the vacuum system composes two independent subsystem, equipped with several closed loop vacuum lines, which carries vacuum regulating system and vacuum displaying system, to ensure stable and even vacuum degree of sheet surface

Haul off Device:

First haul off device is of high power, high reduction gear ratio, multi roll type, high traction, to draw the sheet up from calibrator evenly and synchronizedly.

Second haul off device is to remove stress and equipped with edge cutting device to ensure effective width and smooth cutting.

Cutting Machine: Accurate imported automatic length indicator, adopts electric fly cutting and traversing cutting.

Electrical control system: adopt PLC to control precise parameters.

Process Flow of plastic corrugated plate making machine

Feeding→extrusion→exchange screen→Die→Calibrator→first haul off →heat treating oven →Cooling→second haul off →cutting→stacking

Benefits of plastic corrugated plate making machine

1. Required high production efficiency

2. Production flexibility( controllable sheet thickness and width, for example, you can produce 2-6mm thick sheet with the same mould or machine)

3. Reliability and stability

4.Excellent Adaptability to different raw material and reach over 30% production cost reduction.

5. Size and shape diversity of finished products

Pictures of plastic corrugated plate making machine

1250mm plastic corrugated plate making machine are professionally manufactured through the plastic equipment with more than 15 years' experience

1650mm plastic corrugated plate making machine are CE certified, which assures your legal right.

2150mm plastic corrugated plate making machine are ISO9001:2008 certified, which guarantee the product quality.

2550mm plastic corrugated plate making machine offer the custom service and engineer available to service overseas, which can meet your requirement better and solve the problem in the process of operation.

We will provide wooden case to pack the plastic corrugated plate making machine

1. Pre-sale Service:

1)Select equippment model;

2)Design and manufacture products according to clients' special requirements

3)Train technical personnel for clients

2. Service during the sale

1)Precheck products ahead of delivery

2)Help clients to draft solving plans

3. After-sale Service

1)Provide considerate service to minimize clients' worries

2)Assitant clients to prepare for the first construction scheme

3)Install and debug the equippment

4)Train operators for clients

5)Eaximine the machine

6)Take initiatives to eliminate the troubles rapidly

7)Provide perfect service

8)Provide technical exchange.

Wuhan Handen Machinery Co.Ltd

tel:8613986280012

Skype: anitacao27

Wechat: anita_oo

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece