Elevator systems are widely used in today’s infrastructure and allow people to move vertically inside a structure. The ‘elevator contractor’ is a central component that is often neglected. So, what is an elevator contractor? This guide tries to explain the problems. Their importance and role in elevator operations concern efficiency, precision, and safety. Suppose you are a professional in the field, a building manager, or want to know how elevators work. In that case, this article will provide information regarding contractors, such as how they function, their importance, and modern device advances. Thus, we will examine the elevator contactor, starting from simple matters to its functions in modern elevator technology.

What is an Elevator Contactor, and How Does it Function?

An elevator contractor is an example of an electrically actuated switch that controls the power supply to different parts of an elevator system. It performs as a crucial relay that allows or prevents motors, brakes, and other vital components from functioning. When an elevator is requested to move, the contactor engages and sends power to the motor for smooth operation. After the motor’s task is accomplished, the contactor disengages to cut off power and lock the system. This precise command control ensures safety, efficiency, and reliability in the workings of the elevator.

Understanding Elevator Contactor Basics in Control Systems

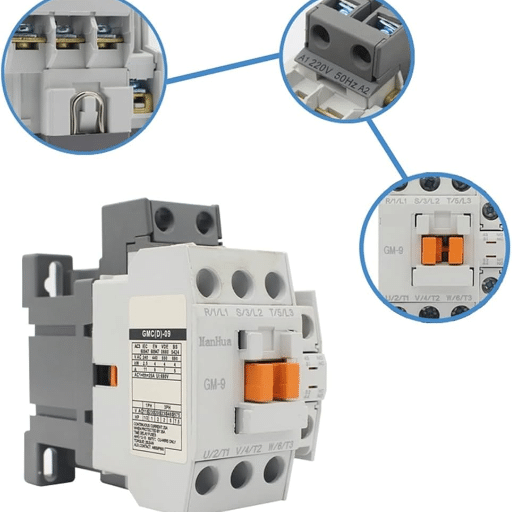

Every functional system incorporates elevating contractors with multiple interrelated constituents. The vital parts are the coil, contact points, arc chutes, and the housing unit. The coil creates a magnetic field that energizes the contact point’s spring mechanism, closing the circuit. Arc chutes add to durability and safety by suppressing electrical arcs during the make-and-break process. The housing protects the casing and other parts from the outer environment and high temperatures.

Contemporary systems use elevators with advanced contactors that facilitate many precise tasks with adequately defined materials that could sustain higher current and voltage. A good example is the contactors compliant with EN81 standards, which have improved capabilities of arc extinguishing, making them less susceptible to wear and prolonged use. Now, some models have incorporated features such as real-time monitoring with auxiliary contacts and thermal overload protection, improving the security of operation and better diagnostics.

Research carried out by elevator manufacturers suggests the new advanced contactors are more efficient, reducing downtimes by around 20% compared to the previous versions. This efficiency is pronounced in urban cities with constant elevator traffic. The other efficiency derived from the contactors comes with power consumption, which could reach 10-15%, making the building more sustainable.

The skilled craftsmanship of elevator contractors ensures that every job fits every type through the gears and workings of both conventional and geared motors. This range of adaptability works well even in skyscrapers and powerhouse buildings. Even in challenging situations, the technology provides seamless coordination and dependable service.

How Contactors Work in Elevator Motor Circuits

Contactors play a vital role as control elements in elevator motor circuits and assist in their reliability and safety. They are primarily used to manage the electricity flow into the elevator motor by either opening or closing the circuit depending on signals received from control centers. This guarantees that the correct voltage and current will be provided to the motor for proper functioning.

Modern elevators use contactors to handle significant power loads of 10 to 500 amperes, depending on the system’s requirements. These pieces of equipment are built with high-grade electromagnet coils that permit accurate control and switching on and off. When the electromagnetic coil is energized, a magnetic field attracts the contact points to close, allowing current to flow to the motor. When the coil is de-energized, springs force the contacts open to disconnect the power to the motor for safety reasons.

The newest contactor models have features such as arc suppression and protective shutoff, essential in averting harm to the motor and adjacent parts in situations of sudden voltage increase or electric bleed power surge. Reports have shown that elevator multifunctional failures have been reduced to 20% in the last decade after such features were included in electrical contractors.

Contactors are used alongside integrated intelligent system supervision and diagnostics in many of today’s elevators. This combination of technologies provides a quick reaction that significantly reduces elevator system downtime and enhances performance. Responding to market needs, contactors with low power consumption have also been developed, simultaneously increasing operational efficiency in servicing high-rise buildings.

The Role of Contactors in Starting and Stopping Elevator Motors

Contactors are essential for adequately starting and stopping elevator motors because they handle the high electric power demands of efficiently and safely operating these systems. When an elevator system is signaled to move, contactor engagement occurs as the contact closes, powering the motor and enabling the elevator’s smooth acceleration. In contrast, when the elevator autonomously decelerates, contactor disengagement occurs, opening the circuit and ensuring power inhibition to the motor, achieving total cessation.

Elevators nowadays use electronic contactor systems for increased performance and accuracy. These systems mitigate electric arcing, which increases the contractor’s durability and reduces maintenance expenses. For example, elevators equipped with Variable Frequency Drives (VFDs) integrate these contactors, allowing them to assist the drives in controlling the motor’s speed and torque during starting and stopping, seamlessly enhancing passenger comfort.

Recent studies show that high-performance contractors are being developed to sustain voltage ratings of up to 1,000 volts, with current handling capabilities of over 2,500 amperes. These global elevator systems require handling large motor systems more efficiently within high-rise buildings. Some modern models also incorporate monitoring functions to display information regarding the electrical flow and the lifespan of the contacts in real-time. This reduces unexpected downtime by ensuring that failures can be predicted and rectified before they happen.

With technology integration, these powerful contractors take on another responsibility: generating reliability and safety risk management in elevators worldwide.

Top Elevator Contactor Brands: Comparing Siemens, Schneider, and Fuji

Evaluation across the Siemens, Schneider, and Fuji elevator contractors reveals all three brands do remarkably well in the reliability and performance sectors within the industry. Schneider is known for the flexible protective measures that this solution incorporates durability, allowing its use within various elevator systems. Siemens concentrates on innovation, providing diverse products with advanced energy monitoring systems like streamlined products that conform to international standards. Fuji emphasizes compact designs with robust materials for smooth operations with low maintenance issues. Fuji also offers precision-engineered parts, thus guaranteeing reliability and safety. Each brand caters to different priorities. Therefore, application requirements and strict budget considerations guide optimal choice.

Siemens Elevator Contactor Specifications and Applications

A comprehensive review of contactors shows Simoens elevator contactors are compact and energy modulators as load modulators. These representatives of Simoens elevator contactors feature robust construction for longevity and provide flexible applications for residential, commercial, and industrial buildings. Integrated Simoens systems are adjustable to the upkeep needs, providing low maintenance integrated control systems while elevated dependability in operational guarantee support for autonomous operation.

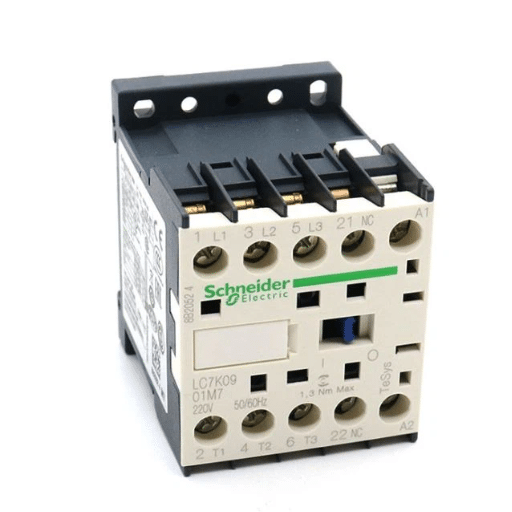

Schneider Electric Contactors for Elevator Control Systems

Schneider Electric’s contractors have proven their worth in the controlled operation of elevators, as they function and innovate with enhanced precision. The advanced materials and modern technology allow these contractors to withstand even the most demanding situations with high durability and constant efficiency. These contractors are suitable for residential, commercial, and industrial elevators, as they can vary load capacities and multi-purpose compatibility.

The unique integration technology that simplifies use while reducing operational expenses is an improved, cost-effective, and energy-efficient feature for these contractors. To illustrate, contactors from the Schneider Electric TeSys range boast low coil consumption and superior thermal protection, resulting in lengthened service life and minimized maintenance. Research also corroborates their compliance with international legally mandated safety standards, optimally protecting systems and users.

Prominent features include space-saving compact cabinet designs and high-level arrangeable switching capacity suitable for heavy workload operations. Furthermore, Smart monitoring Schneider Electric distinguishes itself with seamless compatibility with building automation systems, which allows precise control of system functions. Sustaining their flyer, Schneider Electric’s reputation is consistently upheld as the dependable solution regionally or globally sought by all users and advanced needs of elevator control systems.

Fuji Electric Contactors: Performance and Reliability

Renowned for their remarkable performance, energy consumption, and rigorous engineering, Fuji Electric contactors are designed to function under extreme industrial conditions. They offer exceptional dependability and resilience while operating motors, HVAC systems, and automated factories.

Fuji Electric contractors are renowned for their advanced arc-extinguishing technology, which significantly extends the lifespan of vital components, thereby reducing the need for critical maintenance. Additionally, fuji electric contactors come with noise-reduction mechanisms enabling quiet operation, which is needed in modern industrial facilities. These contractors are offered within a broad range of current ratings from 9A to 800A, providing suitable options for various application demands.

Modern Industry Fuji’s latest series extends global compliance standards like RoHS by incorporating green materials and designs, making them eco-friendly. These contractors guarantee superior thermal and electrical techniques, and their compact and lightweight structures significantly free up space. Enhanced operational efficiency is guaranteed with smart automation controls enabled by PLC systems, precision monitoring, and control.

Stringent testing and quality assurance protocols under normal or extreme field conditions solidify Fuiji Electric contactors’ industry-leading reputation for reliability where endorsed dependability is critical. Fuji Electric’s relentless pursuit of technological advancement and unmatched craftsmanship consistently reshuffles industry standards for contactor innovation.

AC vs DC Elevator Contactors: Which Should You Choose?

Choosing between AC or DC elevator contractors varies from application to application and depends on your elevator system’s power needs. AC contactors offer ease of use and low cost because they work smoothly with standard power supplies. They are suitable for systems where costs must be contained while remaining efficient.

On the contrary, DC contactors are more expensive but offer better performance for high-precision applications like high-speed elevators and ease of maintenance. These contractors also provide reliable operation in rough conditions, which justifies the increased cost.

Choosing the correct option should always depend on the elevator load capacity, speed, and operational goals. As always, professional help is recommended to customize performance effortlessly.

220V Elevator Contactor Applications and Limitations

220V elevator contactors are widely used to control the flow of electricity in an elevator system. They help power the elevators, monitor the starting and stopping cycles and protect the cabinets and motors from electrical damage. These contractors are of paramount help when reliability and accuracy are indispensable for every elevator carrying passengers or goods.

There are also some disadvantages. With very high voltage systems or heavy-duty applications, these 220V contactors may not be the most suitable as they have limited capacity and need much larger unit sizes. Routine maintenance is also essential as the device may be subjected to much strain due to prolonged usage, eventually leading to diminished performance or system failures. Knowing the specific operational criteria and environment allows a decision to be made on whether a 220V contactor is ideal for the system. With good use and professional guidance, these components can be protected, prolonging their use.

AC220V Contactors for Modern Elevator Systems

AC220V contractors are vital in modern elevator systems because of their precision, reliability, and ability to ensure optimal performance and safety. They are manufactured to handle large electrical loads easily, making them a perfect grade for demanding conditions, multi-story masons, and high-traffic places.

AC220V contractors have several key advantages, such as energy efficiency. Optimized ancillary contacts lower the vortices’ operating costs and help fulfill sustainability goals for building management. Their robust construction and improved arc-quenching capability further reduce the chances of fires or electrical faults, making them safer.

AC220V contractors are known to manage current ratings of 9A to 630A, depending on the model, meaning they can be implemented in many different APAC systems. Their versatility and compact structure result in space-saving installations, a critical feature in the modern elevator’s machine room for efficient spatial economy.

The optimizations don’t stop there; other characteristics include integration with intelligent systems and automation technologies for remote monitoring, allowing for real-time analytics. This capability actively decreases downtime and aids in predictive maintenance. The new optimizations include advanced noise-suppressing technology ensuring quiet operation— which is crucial to residential and commercial settings.

Integrating advancements in AC220V contactors allow elevator systems to operate with excellent reliability, improved safety standards, increased energy efficiency, smoother operation, and lower maintenance needs. These innovations make them essential components of contemporary elevator technology.

DC Elevator Contactors: Benefits for Specific Applications

DC elevator contacts are essential in some types of elevator systems, especially those requiring accuracy, dependability, and energy efficiency. DC relays are smoother and more reliable, making them ideal for high-performance elevators in commercial buildings, hospitals, and other industrial settings.

One significant advantage of DC Elevator Contactors is saving energy costs without sacrificing performance in high-load applications. Operating costs can be reduced by almost 30% in modern contractors compared to older technologies, making them more environmentally friendly. Furthermore, other economic advantages can be obtained from enhanced power braking features of DC systems, which are essential for improved safety and comfort for passengers during the ride.

More modern features of DC relay systems also include improved longevity and reduced maintenance required to service the system. Advanced materials, such as those that minimize wear from electrical arcing, significantly improve the serviceable life of the components. Newer DC contactors have also proven cost-effective in the long term by offering more than 1 million switching cycles of practical operation, which means less downtime.

Besides, DC contactors’ small size makes them easier to install in confined areas, which is perfect for new-age elevator systems where every inch matters. Their smart building and IoT system integration features improve their efficiency by allowing for monitoring and maintenance in real-time.

By taking advantage of some features of these DC elevator contractors, building users and developers can improve system safety measures and overall performance and drastically reduce energy consumption, which improves efficiency and supports sustainable development.

Common Elevator Contactor Models and Their Specifications

Several elevator contractor models are commonly used based on their design, functionality, and specifications. Some of the most common ones, together with their essential features, are listed below:

AC Contactor Models: These best function in alternating current powered systems. They are known for endurance in high-frequency applications and reliable performance under continuous use. Typically, AC power systems encompass voltage and current ratings, which are considered key minimum requirements.

DC Contactor Models: These are best suited for direct current systems. They are compact, and have a high endurance in heavy load applications due to high breaking capacity. They often feature magnetic arc blowout brackets, which increase their ability to suppress arcs and make them capable of being heavy-duty. Typical specifications focus on exact voltage ranges and high endurance across varying load conditions.

Hybrid Elevator Contactors: These models leverage Both AC and DC advantages. Their versatility makes them suitable for contemporary systems. Due to their advanced architecture, improved safety features, and energy-efficient designs, they are capable of being smart buildings.

The versatility and customization of specific operational environments allow users to tailor each model to best fit the means and needs of their elevator systems.

CA2KN40P7 Contactor: Features and Compatible Systems

The CA2KN40P7 contactor is efficient and compact, suited to various low-power control and signal-switching applications. Its features include a modular design for effortless installation, long service life, durability with AC and DC control circuit compatibility, and low power consumption. The contactor’s low consumption makes it an energy-efficient selection for contemporary systems.

The CA2KN40P7 is often utilized across elevator control systems and innovative building equipment due to its reliable performance in numerous environmental settings. The contactor aligns perfectly with other Schneider Electric devices, increasing operational efficacy. Moreover, the device performs best in motor or signal control systems up to defined voltage and current limits. The contactor’s sturdy construction and multi-faceted applications render it a trustworthy option for industrial and professional environments.

LC1D Series (LC1D18F7C, LC1D18FDC, LC1D40) Technical Overview

The TeSys D contactors model LC1D series from Schneider Electric has enhanced dependability and more optimized performance on motor controls and other load management applications. The LC1D18F7C, LC1D18FDC, and LC1D40 models are lightweight and compact for easy lifting but tough, so they can handle operations of 18A or 40A, depending on which variant is used. These also support AC and DC circuits, making them useful for commercial and industrial purposes.

Significant advantages for these contractors include improved compatibility with the AC and DC coil voltages, which means better flexibility and ease of integration into existing systems. Added support for these devices also increases their performance as lower maintenance is required. These models comply with various covers, such as IEC 60947 and UL certifications, making them reliable and safe for use in any environment.

When deciding between the options, we suggest paying attention to control voltage, load requirements, and other application-specific details. These contractors perform best when working with Schneider Electric solutions, as they guarantee non-stop system compatibility and performance.

LP1K090085MDS35 and LC7K0901M7 Performance Characteristics

The LP1K090085MDS35 and LC7K0901M7 are compact and versatile industrial contactors. The LP1K090085MDS35 high-performance 3-pole contactor processes both AC and DC control applications. Its compact dimensions permit the integration of auxiliary contacts, making it compatible with modern control panels. Its nominal operational current is 9A for AC-3 category applications, and it can be operated at voltages up to 690V.

The LC7K0901M7 contactor also offers reliable performance, although it favors efficient switching. It operates on applications that require 1-phase or 3-phase motors. The LC7K0901M7 has a rated 9A at 400V (AC-3) operational current, perfect for starting and stopping motors. It enjoys a wide operating temperature range and is made from tough materials to withstand harsh conditions for a long time.

Both models carry a wide range of Schneider Electric’s accessories, which sharpen industrial customization requirements. Moreover, these contractors meet uncompromising safety and performance standards, operating reliably in manufacturing, automation, energy management, and other sectors. Their reduced power consumption and efficient coil design lowered overall energy costs associated with the contactors, making them a modern, sustainable industrial shift.

Elevator Contactor Maintenance and Troubleshooting

Steps on Why Regular Maintenance is Important: Regular maintenance attendance on elevator contractors is essential to guarantee safe and efficient operation. Maintenance routines check for possible hazards, overheating, or performance-inhibiting dirt accumulation. Dirt and misalignments of parts increase the probability of contact malfunction, and as such, they must be minimized by cleaning contact areas and proper alignments.

Common Issues and Solutions:

Contact Wear or Pitting: Greater operative inefficiency arises from reduced conductivity caused by worn or pitted contacts. Timely replacement of faulty contacts ensures the absence of operational inefficiencies.

Coil Issues: Coil malfunctioning usually leads to non-operation through burned-out or damaged coils. Measuring the coil’s resistance will help evaluate the need to replace it.

Excessive Noise: Loose constituents and voltage variations often generate hissing or humming. Connection checks and inspection of the voltage supply must be carried out.

Overheating: Failure to complete contact cleaning may lead to prolonged operation, which in turn causes overheating. The described thermal stress must be resolved by mitigating the defined root issue while cleaning or replacing components.

Proper issue resolution and regular maintenance on a fixed schedule can achieve a safe and optimally functional contactor. Ensure that a manufacturer’s instructions and guidelines are always available for reference during procedure outlines.

Common Elevator Contactor Issues and Electrical Troubleshooting

In elevator contractor repair and electrical troubleshooting, I emphasize orderly root cause analysis. I look for burned parts and loose or corroded electrical connections. If parts are clean, I ensure the surrounding environment is free of potential contaminants. In case of overheating, I check the operating environment, clean the environment, and replace worn parts as required. I also routinely abide by the manufacturer’s maintenance and repair recommendations to enhance safety, efficiency, and risk mitigation.

Maintenance Schedule for Lift Contactors and Control Systems

I have a defined maintenance plan for the lift contactors and control systems. I perform monthly scheduled inspections, looking for general housekeeping issues, loose parts, and damaged parts. I do quarterly maintenance by cleaning all electrical parts and checking thermal controls to avoid overheating. In yearly maintenance, I check and replace worn components, conduct thorough system inspections, and perform functional safety tests. This approach helps proactively ensure reliable performance over time.

When to Replace vs. Repair Elevator Contactors

Factors such as cost efficiency, safety, and extent of wear are paramount when deciding to repair or replace elevator contractors. Contactors in an elevator system are of utmost importance as they facilitate the movement of the elevator and control circuits, which power on and off various parts of the system.

Signs It Is Time To Replace a Contactor: Contactors can show signs of advanced wear, such as burnt/pitted contacts, discoloration, or simply making a loud and unusual noise for the duration of the operation, which would require replacement. According to industry benchmarks, contactors commonly fail under standard conditions in 3 to 5 years. However, the contractors may fail much sooner in high-traffic buildings with heavy elevator use. For instance, research indicates that in high-quality contractors, beyond 10 million operational cycles, severe inefficiency and system failure become a reality.

When Repairs May Be Possible: If the contractors show signs of minor damage, like worn-out contacts or loose connections, then repairs can be attempted. In some cases, reconditioning contact tips or the spring mechanisms can prolong the lifespan of the contactor by as much as a year. Repair, however, should not compromise the dependability of safety features. Evaluating the cost-benefit is of the utmost importance in this case; if the repair cost surpasses 50 percent of the cost of replacing the unit, then replacement is the way to go.

Safety and Compliance Considerations: Apart from functional damage, repair, or replacement, contactors should adhere to the latest safety standards and building codes. Regulatory non-compliance of such nature could result in pernicious fines or complete operational shutdown in highly regulated settings. Moreover, modern elevator systems may also require contactor replacement for compatibility with energy-efficient or intelligent control systems.

Timely modern servicing and scheduled evaluations guarantee that the parts are repaired and replaced correctly, thus limiting operational disruption while improving passenger safety.

Where to Source Quality Elevator Contactors and Spare Parts

When looking for quality elevator contractors and spare parts, reaching out to industry suppliers and manufacturers with established reputations is critical. Focus on firms that deal in elevator parts and offer certified compliant components. Authorized distributors for reputable brands usually stock genuine parts with a warranty. Some manufacturers also provide online catalogs and direct purchasing to streamline the sourcing process. Prioritize customer information like detailed product specifications, support, and fast turnaround times for shipping to guarantee prompt repairs and upgrades.

Reliable Elevator Contactor Suppliers and Manufacturers

While looking for elevator contractors, it is vital to look up suppliers and manufacturers known for their trust, product quality, and certifications from relevant industries. Schneider Electric, ABB, and Siemens are some companies recognized worldwide for supplying highly reliable elevator contactors that pass all the required safety and electrical tests. Several manufacturers offer helpful technical documents for routine maintenance and installation tasks.

Some specialized elevator component suppliers are beneficial in creating curated product catalogs, and they offer some of the best elevator components, like competitive pricing and customer-tailored support. Many Wittur or Fermator companies known for their expertise in most parts of the elevator systems tend to supply contractors and various other associated components. They can provide a lot of different elements and parts along with bulk supply discounts, which helps improve the efficiency of a given project.

Reports by the industry overview state that Tier 1 suppliers are still focused on innovation, such as developing more innovative and energy-efficient contactors for intelligent elevators. With such innovations, elevators work smoothly, and energy conservation for long-term usage is ensured. Reliable distributors with technicians who know what they are doing are a priority for people working with elevator servicing, repairs, and installations.

Customer Reviews of Popular Elevator Contactor Brands

Schneider Electric: Elevator contractors by Schneider Electric are praised in the industry for their robust performance and energy-efficient designs. Customers highlight their elevators’ reliability, long lifespan, and seamless modern integration. Over half of the maintenance providers report an apparent breakdown reduction when using Schneider Electric’s units and parts. Global support and accessible technical documentation also receive high praise.

Eaton: Eaton’s contactors are widely recommended for their energy efficiency and compact size. Facility operators also highly appreciate the ease of installation and absolute reliability under heavy usage. User reviews greatly appreciate the focus on sustainability, noting that numerous Eaton products qualify for green building certifications. Customer feedback praises prompt delivery and responsive after-sales service.

ABB: Pioneering innovative engineering and accurate manufacturing, ABB is well-regarded throughout the industry. Their contractors, widely used in skyscrapers and other tall buildings, are well-known for fault tolerance, impressive performance in reliable component use, and reduced operational downtime. Continuous investments into innovative technologies appeal to customers seeking future-ready solutions.

Siemens: Siemens takes pride in earning positive feedback for their contactor systems, as they are exceptionally flexible and work with IoT-interfaced elevators. Users of the brand’s products value the innovations as well as the quality of the products. Their global coverage and fast support services significantly boost customer satisfaction. Customers overwhelmingly appreciate the Siemens casing to their components as it simplifies servicing and maintenance.

Mitsubishi Electric: Mitsubishi Electric contractors are among the high-end classified products as they incorporate several technologies. Their reliability is praised by several users, who realize demanding tasks in commercial structures and public works. Many of the company’s customers highlight the favorable blend of operational life, energy efficiency, and eco-friendliness, which leads to its widespread preference amongst lift manufacturers. Mitsubishi Electric is noted for its proactive customer relations and long product warranty periods.

Using vivid language, these profound comments illustrate the consistency and innovation incorporated by the foremost brands in elevator contractors, which guides consumers in the buying process.

Finding Compatible Spare Parts for Elevator Control Systems

Choosing accurate replacement parts for elevator control systems is equally crucial for the equipment’s performance and reliability. One type of spare part is contactors, which are used in elevators with sensors and control boards. Other standard spare parts are relays, board PCBs, sensors, and motor control systems.

Understanding the model and technical specifications of the specific control system is always the first step. Most manufacturers provide their clients with supplementary catalogs containing the part lists or guide manuals that come with documents explaining the features of the parts. For instance, some brands use systems with 24V relays while others use 48V relays; thus, picking the wrong component would harm the entire system.

Research shows that the majority of control systems are entirely above fifty percent of the elevator downtime, which coincides with the breakdown of system components. This indicates that fake or poor-quality spare parts have been used for replacements. OEM (original equipment manufacturer) parts are recommended because of their unmatched quality. Otis and Mitsubishi Electric are some leading brands offering spare parts怕slisted to avoid counterfeiting.

Moreover, the Internet has simplified the process of looking for spare parts due to search engines. Major distributors and suppliers offer their customers sophisticated specifications, technical datasheets, and documents detailing the compatibility of parts, which assists customers in making their decisions. Searching through dedicated parts databases also streamlines the process and minimizes the chances of incorrectly ordered parts.

For companies with several elevators in service, having a stock of necessary spare parts can reduce breakdown time associated with component malfunctions. This approach, tailored to provide maximum uptime and control, enhances the reliability and longevity of the entire control system. Careful consideration of parts for compatibility, quality, and sourcing allows the preservation of agile and dependable elevator systems.

Reference Sources

The following is a summary of key findings and approaches related to elevator contractors and their applications:

-

Relay Contactor System for Linear Electric Drives2:

- Key Findings: This study explores the use of relay-contactor systems for controlling linear electric drives, including applications in elevators. The system automates starting, stopping, and speed control operations, ensuring optimal resource use and reduced operational costs. It highlights the advantages of relay-contactor systems, such as high noise immunity and significant switching power, while noting limitations like contact wear and energy consumption.

- Methodology: The research involved simulating relay-contactor systems under various interference signals and analyzing their performance in real-world industrial applications.

-

Siemens PLC-Controlled Elevator Design4:

- Key Findings: This paper discusses the design of a four-story elevator system controlled by Siemens S7-200 PLC. It emphasizes using programmable logic controllers (PLCs) for efficient and reliable elevator operation, including speed control and safety mechanisms.

- Methodology: The study involved hardware and software design, including I/O assignments, ladder diagram programming, and testing with MCGS configuration software to create a user-friendly interface.

-

Elevator Technology Improvements: A Snapshot5:

- Key Findings: This review highlights advancements in elevator technology, such as rope-less systems, AI integration, and IoT-enabled maintenance. It also discusses innovations like regenerative drives, which recycle energy during braking, and holographic buttons for touchless operation.

- Methodology: The paper compiles and organizes extensive research on elevator design and technology, providing a non-technical narrative for broader accessibility.

These studies collectively provide insights into the advancements in elevator contractor systems, focusing on automation, energy efficiency, and user safety.

Frequently Asked Questions (FAQs)

Q: What is the purpose of LC1D18F7C elevator contactors in elevator systems?

A: LC1D18F7C elevator contactors are crucial electromagnetic switching devices in elevator control systems. They’re designed to establish and interrupt power circuits controlling motor operation. These contractors handle the high inrush currents during elevator start-up while providing reliable electrical isolation when the elevator is stationary. They’re a vital component in elevator controllers, ensuring the safe and efficient operation of the entire elevator system while protecting other elevator circuit boards and components from electrical overloads.

Q: How do D3N LC1N3201M5N LC1-N3201 contactors differ from standard AC contactors?

A: D3N LC1N3201M5N LC1-N3201 contactors are specialized versions explicitly designed for elevator applications, unlike standard AC contactors. They feature enhanced electrical and mechanical durability to withstand the frequent switching cycles in elevator operations. These contractors typically include noise suppression capabilities to prevent interference with elevator sensors and encoders. They also come with safety certifications specific to vertical transportation systems. They are designed to integrate seamlessly with modern elevator control systems, including those that operate elevator door operators and elevator drive inverters.

Q: What are the maintenance requirements for low-voltage contactors in elevator systems?

A: Low voltage contactors in elevator systems require regular inspection for contact wear, proper tension, and signs of overheating. Maintenance should include checking terminal connections for tightness, cleaning contact surfaces to remove dust or oxidation, and testing coil resistance and insulation. Technicians should verify the operation of auxiliary contacts that might control elevator buttons and automatic control systems. Typically, a quarterly visual inspection is recommended, along with comprehensive testing annually. When replacing worn contactors, ensure compatibility with existing elevator circuit boards and control systems to maintain the integrity of safety features like elevator light curtains.

Q: How do LS contactors function within elevator control systems?

A: LS contactors in elevator control systems serve as reliable switching devices that control the power to different elevator components. They establish electrical circuits when energized and break them when de-energized, managing power distribution to motors, brakes, and door mechanisms. These contractors work with elevator controllers to execute commands from elevator buttons and respond to signals from elevator sensors. Their robust design handles frequent switching cycles while protecting against electrical faults. LS contractors often incorporate surge protection features that safeguard sensitive components like elevator circuit boards and encoders from voltage spikes, ensuring the consistent operation of elevator drive inverters and other critical systems.

Q: What safety features are built into SC-N1 contactors for elevator applications?

A: SC-N1 contactors incorporate several safety features crucial for elevator applications. They feature fail-safe design principles, ensuring they default to a safe state during power loss. They include electrical and mechanical interlocks preventing simultaneous activation of conflicting movements and arc suppression technology minimizing contact wear and fire hazards. These contractors also have enhanced insulation for electrical isolation, protecting sensitive components like elevator circuit boards. Additionally, they’re designed with monitoring capabilities for integration with elevator safety circuits, including those connecting to elevator light curtains, elevator locks, and elevator door lock mechanisms, ensuring passenger safety in compliance with elevator safety standards.

Q: How do elevator contractors interface with elevator door operators and locks?

A: Elevator contactors interface with door systems through specialized control circuits that ensure proper sequencing and safety. They receive signals from the central controller to initiate door operations at appropriate times. They also monitor feedback from elevator door locks and female locks to verify secure closure before allowing car movement. These contactors control power to the door motor while interfacing with safety devices like elevator light curtains and elevator door vanes. To prevent injury, the system incorporates time-delay circuits to manage door open/close timing and force limitation features. Specialized contractors may also manage power to electromagnetic locks, ensuring doors remain securely closed during travel while providing emergency release capabilities when needed.

Q: What are the common troubleshooting steps for AC contactors in elevator systems?

A: When troubleshooting AC contactors in elevator systems, first check for visible damage, burning, or wear on contacts. Verify proper voltage at the contactor coil and inspect control circuit fuses. Listen for the distinctive click of contactor operation and check for appropriate contact closure. Measure voltage drop across closed contacts to identify high-resistance connections. Inspect elevator circuit boards for fault codes related to contactor operation and verify signals from elevator sensors and elevator encoders that might affect contactor activation. Check mechanical linkages to elevator buttons and switches. Monitor temperature during operation for intermittent issues, as overheating often precedes failure. Always ensure replacement contactors match specifications for the elevator drive inverter and control system requirements.

Q: How do low-voltage contactors protect elevator circuit boards and small spare parts?

A: Low voltage contactors protect elevator circuit boards and small spare parts through several mechanisms. They provide electrical isolation that prevents voltage surges from reaching sensitive electronics and incorporates arc suppression to minimize electromagnetic interference that could damage microprocessors on circuit boards. These contactors feature precise current limiting capabilities that prevent overloads, protecting components like elevator decoders and sliders. Their mechanical construction creates a physical separation between power and control circuits, reducing the risk of catastrophic failures. Many modern contractors include electronic monitoring that can detect abnormal conditions before they cause damage to the elevator drives, inverters, or circuit boards, facilitating predictive maintenance rather than reactive repairs of expensive components.

Q: What considerations are essential when selecting replacement contactors for elevator control systems?

A: When selecting replacement contactors for elevator systems, match electrical ratings precisely, including voltage, current capacity, and coil voltage. Verify physical dimensions and mounting configurations for proper fit in existing panels. Ensure compatibility with control signals from elevator controllers and check for necessary auxiliary contacts to interface with elevator buttons and sensors. Consider the duty cycle rating based on elevator usage patterns and verify that the contractor meets the required safety certifications for elevator applications. For components like LC1D18F7C elevator contractors or D3N LC1N3201M5N models, confirm they support integration with modern features such as elevator light curtains and elevator drive inverters. Finally, future maintenance should be considered by selecting contactors with available spare parts and good manufacturer support.