Elevator Contactor Insights & Buyer's Guide

For the proper use of an elevator device in a single- or multi-story building, a reliable elevator contractor is necessary because it ensures the safety and smooth operation of the elevator system. All types of buildings, whether residential towers or simple office spaces, can achieve superb performance with proper management of their elevator controllers, while maintaining a user-satisfactory and optimal standard. Learn how AC contactors with coils of AC110V grade improve your AC elevators and get connected with site-specific industrial solutions.

What is an Elevator Controller and How Does it Work?

The Importance of Contractors in an Elevator System

Elevator contactors are important in the electronic parts of the unit as they aid in starting and stopping the elevator. They are responsible for motor control in an elevator system. Contactors allow a circuit to be made for the relay coils and charge them. They also maintain the current, which is essential for the elevator's functions. Contacts further enhance the effectiveness of the elevator by ensuring the current is not interrupted. This leads to building experience together with enduring satisfaction.

Why Every Elevator Should Have AC110V Alloy Cruciforms.

Every elevator equipment ought to be composed of the coil and the contacts, which have a Plug-in/Crimp Terminal. The reason is that the inclusion of the AC110V coil is fundamental as it serves as a primary power switch activator everywhere. Moreover, all these copper-gold alloys should be accommodated within a housing. At the same time, the relay coil's motion is of great significance, as it controls the performance of the main contactor, ensuring the timely switching of the specific circuit. Employing this order of universal contractors helps avoid issues like overheating.

How Electric Feedback Improves Safety and Efficiency in Elevators

Feedback systems in the electric circuit offer vital details on current flow and control the elevator’s operation. As elevators are a sophisticated system, their control system is based on modern elevator technology that utilizes computers. Feedback control enhances operational efficiency and elevates safety policies. In modern-day electrical systems, feedback systems play a key role in safety measures. During overload scenarios, electrical feedback enhances safety as it enables systems to respond and automatically reduce power drops or overload conditions. In this scenario, the motor is controlled to stop. In essence, feedback control helps achieve a desired goal, thus increasing efficiency and safety measures. Safeguards amplify control and enhance the proactivity of elevator systems, which reduces the wear on equipment.

How to Choose the Right AC Contactor for Your Elevator?

Key Features to Consider When Buying Elevator Contactors

Contractor settings, such as coil voltage, current ratings, and the manufacturer’s name, can impact the choice of an elevator contactor. The elevator system’s specific requirements dictate the functionality of the contactor. The contractor must at the very least meet the elevator equipment’s electrical requirements. This will ensure reliable and stable operation under different circumstances. Looking at elevator contactors with these features makes it easier to make an informed purchase decision.

Comparing Lift Contactor Types and Their Specifications

Having multiple lift contactor types provides an opportunity to exploit their specific operational advantages. Different models of contractors can be easily compared based on load capacity, voltage, and electrical endurance, which further assists in selecting the best-suited contractor. The goal is to analyze the specifications of various lifters and select the most durable and high-performing ones for the elevator systems.

Investing In Custom Reviews and Evaluations

For a complete understanding of an elevator contactor's performance in real-life scenarios, you can equally rely on customer reviews and ratings. This feedback helps you gauge the reliability, ease of use, durability, and other essential features of the contactors. It's best always to select products with good reviews and high ratings to ensure you're making a valuable investment in your elevator system.

What Are the Benefits of Using Fuji Electric Contactors?

The Benefits of Using Fuji Electric Products in Elevator Systems

In the case of electric products for escalators and elevators, Fuji Electric is well-known worldwide due to its unparalleled quality and technology. This company is famous for its innovative and dependable products, designed for contractors with unmatched control, endurance, and safety. With Fuji Electric contactors, you integrate contractors that are enhanced with advanced technology, which improves the functioning and productivity of elevators.

Fuji AC Contactors Reliability and Efficiency

These contactors come with the precision to control the wear and strain that comes from rigorous operational environments. The constant, dependable performance of these contacts is guaranteed due to their effortless handling capability on higher current loads. Fuji Electric has used robust construction and advanced materials, which result in lower maintenance and fewer replacement needs. This is economically beneficial for users, as the life cycle of the contacts is extended.

How Fuji Electric Ensures The Best Control of Current

Fuji Electric contactors are built with accurate current control, which is critical for the efficient operation of elevators. Their construction utilizes advanced technology that controls the flow of electricity with great accuracy, helping to avoid electrical problems like overloads and short circuits. With proper current control, as implemented in Fuji Electric contactors, elevator operators can enhance safety and efficiency, improving performance and reliability.

How to Properly Maintain and Service an Elevator Controller?

Best Practices for Lift Contactors Maintenance

It is essential to maintain relational contacts, since they affect productivity and lifespan. Cleanliness is next to godliness, therefore components need to be checked for dust accumulation. Regular inspections are necessary to check for proper connectivity and identify any wear and tear. Having a good, well-worked-out maintenance schedule that is followed will help prevent lift systems from sudden and unplanned breakdowns.

Common Problems: Will AC Contactors Breakdown

The most common issues with AC contactors include coil failure, abnormal circuit behavior, and contacts sticking together. Identifying these problems early helps eliminate prolonged downtime and expensive damage to repair. Lack of intention is the main obstacle to solving many complex issues that require detailed knowledge of electrical systems. Many complex problems can be effectively solved by replacing damaged parts and backing components with those that have the correct readings, supplied in terms of volts and amps.

Potential Dangers When Servicing Electrical Components

Accidents and injuries related to working with electrical parts can be easily avoided by following established safety policies. Using adequate PPE is essential in any maintenance or repair work done on an active circuit. All circuits should be turned off first. To eliminate the underlying factor that causes technicians to receive unwelcome electrical shocks, following the medic and mouse protocols ensures that the proper safety codes are in place.

Where to Buy and Order Quality Elevator Contactors?

Best Rate Elevator Contractor Price Comparison

Purchasing online has numerous options that allow you to buy elevator contactors at the best price, all within your financial capabilities. Numerous suppliers offer favorable pricing and special deals that allow users to get quality contractors without overspending. Ensure quality is guaranteed while browsing online for marketplaces with the best prices.

Reliable Suppliers and Vendors of Contactors

Having long-lasting partnerships with credible suppliers and vendors gives you the advantage of getting premium contractors and quality backup and support services. Search actively for vendors who have been in business for a while and have positive reviews and testimonials from past customers. Trustworthy distributors provide detailed product information and services tailored to help you make the right buying decisions.

Getting in Touch with Suppliers to Get the Product Specifications and Make Orders

Having the proper contacts with the right suppliers ensures that obtaining detailed product information and placing orders becomes an easy task. Always ensure you have all the sufficiently detailed requirements and specifications to enable easy collection of the goods to purchase. Suppliers offer a range of ways to make queries, including through email, calls, or online forms, and provide accurate information on time.

Frequently Asked Questions (FAQs)

Q: What is the description of an Elevator Contactor: AC, AC110V Coil, Industrial Relay?

A: An Elevator Contactor with an AC 110V coil is an industrial relay designed to control electrical circuits in elevator systems. It operates with an AC and features a coil that is energized at 110 volts.

Q: How does an Elevator controller function in an elevator system?

A: An Elevator controller acts as a switch to control the power supply to the elevator motors and other components. It opens or closes the circuit based on control signals from the elevator's control system.

Q: What are the main components of an Elevator Controller?

A: The main components of an Elevator Contactor include a coil, contacts, a housing, and auxiliary contacts. The coil generates a magnetic field, which opens or closes the contacts to control the flow of electric current.

Q: What are the advantages of using an AC110V Coil in Elevator Contactors?

A: Using an AC 110V coil in Elevator Contactors provides compatibility with common electrical systems, efficient performance in controlling elevator operations, and ensures safe and reliable operation in industrial settings.

Q: How can one ensure the longevity of an Elevator Controller?

A: To ensure the longevity of an Elevator Contactor, regular maintenance such as cleaning, inspection for wear and tear, and timely replacement of worn-out components should be conducted. Additionally, ensuring proper installation and avoiding overloading can prolong its lifespan.

Q: What safety precautions should be taken when installing an Elevator Controller?

A: Safety precautions include turning off the power during installation, following the manufacturer's installation guidelines, and verifying that the contactor is rated appropriately for the specific load and application to prevent electrical hazards.

100% Original Mitsubishi Elevator Contactor SD-T21/SD-T35 AC110,AC220V,DC48V,DC125V.US$ 15MOQ: 1 PieceWarranty: 12 monthsType: Control SystemSuitable for: ElevatorTransport Package: cartonXi'an Oan Lift Parts Co.,Ltd

100% Original Mitsubishi Elevator Contactor SD-T21/SD-T35 AC110,AC220V,DC48V,DC125V.US$ 15MOQ: 1 PieceWarranty: 12 monthsType: Control SystemSuitable for: ElevatorTransport Package: cartonXi'an Oan Lift Parts Co.,Ltd Elevator Contactor LC1D80 AC110US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: LC1D80Nantong Jinta Elevator Components Co., Ltd.

Elevator Contactor LC1D80 AC110US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: LC1D80Nantong Jinta Elevator Components Co., Ltd. Hot Sale 240V Elevator ContactorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: 3RH1911-2GA22Beijing Yunchang Elevator Co., Ltd.

Hot Sale 240V Elevator ContactorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: 3RH1911-2GA22Beijing Yunchang Elevator Co., Ltd. New Hyundai UMC25 Elevator ContactorUS$ 5.5 - 9.2MOQ: 1000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: Sahai or OEMModel Number: UMC seriesType: Residual CurrentWenzhou Sahai Electrical Co., Ltd.

New Hyundai UMC25 Elevator ContactorUS$ 5.5 - 9.2MOQ: 1000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: Sahai or OEMModel Number: UMC seriesType: Residual CurrentWenzhou Sahai Electrical Co., Ltd. 400V 63A 4P Modular Contactor,Elevator ContactorUS$ 2 - 10MOQ: 500 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: WEHOPEModel Number: LCH8 elevator contactorElectricity Type: ACYueqing Houpu Trading Co., Ltd.

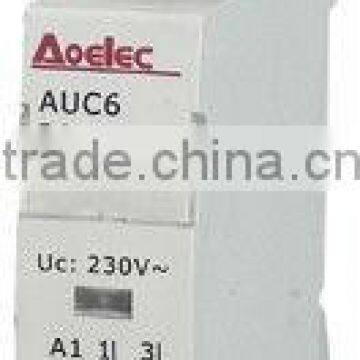

400V 63A 4P Modular Contactor,Elevator ContactorUS$ 2 - 10MOQ: 500 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: WEHOPEModel Number: LCH8 elevator contactorElectricity Type: ACYueqing Houpu Trading Co., Ltd. AUC6 2P 25A Electrical Modular Elevator ContactorUS$ 5 - 10MOQ: 360 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: AOELEC/OEMModel Number: AUC6Electricity Type: ACWenzhou Aoelec Electrical Co., Ltd.

AUC6 2P 25A Electrical Modular Elevator ContactorUS$ 5 - 10MOQ: 360 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: AOELEC/OEMModel Number: AUC6Electricity Type: ACWenzhou Aoelec Electrical Co., Ltd. Elevators Door Contact Oblong,Elevator Contactor,Elevator PartsUS$ 1 - 50MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: Elevators PartsSuzhou Threemicro Household Products Co., Ltd.

Elevators Door Contact Oblong,Elevator Contactor,Elevator PartsUS$ 1 - 50MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: Elevators PartsSuzhou Threemicro Household Products Co., Ltd. Best Selling SC-4-1 Imported Elevator Contactor for SaleNegotiableMOQ: 1 PiecePlace of Origin: Anhui, ChinaBrand Name: OEM elevator contactorModel Number: SC-4-1Anhui I-Sourcing International Co., Ltd.

Best Selling SC-4-1 Imported Elevator Contactor for SaleNegotiableMOQ: 1 PiecePlace of Origin: Anhui, ChinaBrand Name: OEM elevator contactorModel Number: SC-4-1Anhui I-Sourcing International Co., Ltd. Elevator DC ContactorUS$ 10 - 65MOQ: 20 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: ChenfModel Number: CF50Electricity Type: DCYueqing Chenf Electric Co., Ltd.

Elevator DC ContactorUS$ 10 - 65MOQ: 20 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: ChenfModel Number: CF50Electricity Type: DCYueqing Chenf Electric Co., Ltd. Contactor ul dc Contactor 48v Contactors Manufacturers Air Cooler Portable Electrical Supply Elevator Magnetic Contactor SiemensUS$ 1.7 - 3.6MOQ: 10 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: Hvacstar or OEMModel Number: SA-2P-30A-220VACElectricity Type: ACMingguang Hecheng Electrical Co., Ltd.

Contactor ul dc Contactor 48v Contactors Manufacturers Air Cooler Portable Electrical Supply Elevator Magnetic Contactor SiemensUS$ 1.7 - 3.6MOQ: 10 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: Hvacstar or OEMModel Number: SA-2P-30A-220VACElectricity Type: ACMingguang Hecheng Electrical Co., Ltd. 400v Electric Motor ac Magnetic Mitsubishi Elevator Hyundai ContactorUS$ 2.2 - 28.5MOQ: 5 PiecesPlace of Origin: Guangdong, ChinaBrand Name: CGZModel Number: CJX2(LC1)Electricity Type: ACFoshan Guangzhu Electrical Co., Ltd.

400v Electric Motor ac Magnetic Mitsubishi Elevator Hyundai ContactorUS$ 2.2 - 28.5MOQ: 5 PiecesPlace of Origin: Guangdong, ChinaBrand Name: CGZModel Number: CJX2(LC1)Electricity Type: ACFoshan Guangzhu Electrical Co., Ltd. SC-N2 (35) Contactor Electromagnetic Exchange Contactor Elevator Only SC-N2 35A AC110V Two Open Two ClosedUS$ 48 - 68MOQ: 1 PieceBrand Name: YXSModel Number: SC-N2 (35)Shenzhen YXS Technology Co., Ltd.

SC-N2 (35) Contactor Electromagnetic Exchange Contactor Elevator Only SC-N2 35A AC110V Two Open Two ClosedUS$ 48 - 68MOQ: 1 PieceBrand Name: YXSModel Number: SC-N2 (35)Shenzhen YXS Technology Co., Ltd. Elevator Contactor SEL1-A1Z P 6016369045US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: SEL1-A1Z PNantong Jinta Elevator Components Co., Ltd.

Elevator Contactor SEL1-A1Z P 6016369045US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: SEL1-A1Z PNantong Jinta Elevator Components Co., Ltd. Hot Sale Magnetic dc Elevator ContactorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: GMD-12Beijing Yunchang Elevator Co., Ltd.

Hot Sale Magnetic dc Elevator ContactorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: GMD-12Beijing Yunchang Elevator Co., Ltd. Hot Sale Elevator Contactor MG4D/MG5/MG6-BFUS$ 30MOQ: 1 PieceWarranty: 12 monthsType: Control SystemSuitable for: ElevatorTransport Package: cartonXi'an Oan Lift Parts Co.,Ltd

Hot Sale Elevator Contactor MG4D/MG5/MG6-BFUS$ 30MOQ: 1 PieceWarranty: 12 monthsType: Control SystemSuitable for: ElevatorTransport Package: cartonXi'an Oan Lift Parts Co.,Ltd AUC6 3M 40A With Semko Certificate Electrical Modular Elevator ContactorUS$ 5 - 15MOQ: 360 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: AOELEC/OEMModel Number: AUC1Electricity Type: ACWenzhou Aoelec Electrical Co., Ltd.

AUC6 3M 40A With Semko Certificate Electrical Modular Elevator ContactorUS$ 5 - 15MOQ: 360 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: AOELEC/OEMModel Number: AUC1Electricity Type: ACWenzhou Aoelec Electrical Co., Ltd. Elevator Contactor Source ID.NR.176098 Mg5 MG6 ID.NR.176130US$ 1 - 50MOQ: 1 PiecePlace of Origin: ChinaBrand Name: elevatorModel Number: elevator contactor source ID.NR.176098 mg5 MG6 ID.NR.176130Suzhou Threemicro Household Products Co., Ltd.

Elevator Contactor Source ID.NR.176098 Mg5 MG6 ID.NR.176130US$ 1 - 50MOQ: 1 PiecePlace of Origin: ChinaBrand Name: elevatorModel Number: elevator contactor source ID.NR.176098 mg5 MG6 ID.NR.176130Suzhou Threemicro Household Products Co., Ltd. 230V/400V 1-63A 1P-4P Household Elevator ContactorUS$ 1 - 10MOQ: 1 PiecePlace of Origin: Zhejiang, ChinaBrand Name: WEHOPE elevator contactorModel Number: LCH8 elevator contactorElectricity Type: ACYueqing Houpu Trading Co., Ltd.

230V/400V 1-63A 1P-4P Household Elevator ContactorUS$ 1 - 10MOQ: 1 PiecePlace of Origin: Zhejiang, ChinaBrand Name: WEHOPE elevator contactorModel Number: LCH8 elevator contactorElectricity Type: ACYueqing Houpu Trading Co., Ltd. Top Quality Factory Direct Supply SC-4-1 Elevator Contactor for DiscountNegotiableMOQ: 1 PiecePlace of Origin: Anhui, ChinaBrand Name: OEMModel Number: SC-4-1Anhui I-Sourcing International Co., Ltd.

Top Quality Factory Direct Supply SC-4-1 Elevator Contactor for DiscountNegotiableMOQ: 1 PiecePlace of Origin: Anhui, ChinaBrand Name: OEMModel Number: SC-4-1Anhui I-Sourcing International Co., Ltd. Elevator Parts SC-E05A ContactorNegotiableMOQ: 1 PiecePlace of Origin: ChinaBrand Name: xinaoModel Number: SC-E05ABeijing Yunchang Elevator Co., Ltd.

Elevator Parts SC-E05A ContactorNegotiableMOQ: 1 PiecePlace of Origin: ChinaBrand Name: xinaoModel Number: SC-E05ABeijing Yunchang Elevator Co., Ltd. Hot Sale Elevator Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: SC-N2Beijing Yunchang Elevator Co., Ltd.

Hot Sale Elevator Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: SC-N2Beijing Yunchang Elevator Co., Ltd. Elevator 110V ac Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: ChinaBrand Name: XinAoModel Number: GMC-65Beijing Yunchang Elevator Co., Ltd.

Elevator 110V ac Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: ChinaBrand Name: XinAoModel Number: GMC-65Beijing Yunchang Elevator Co., Ltd. Elevator ac Magnetic Contactor 110VNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: 3TF31Beijing Yunchang Elevator Co., Ltd.

Elevator ac Magnetic Contactor 110VNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: 3TF31Beijing Yunchang Elevator Co., Ltd. Purchasing Director is sourcing lowest price assist magnetic contactor for elevator parts2026-01-04 11:44:51

Purchasing Director is sourcing lowest price assist magnetic contactor for elevator parts2026-01-04 11:44:51 Importer placed an order for hot sale for elevator parts electrical magnetic contactor2026-01-04 19:16:25

Importer placed an order for hot sale for elevator parts electrical magnetic contactor2026-01-04 19:16:25 Operations Head negotiating terms for Elevators Spare Parts/Elevator 161 Contactor Door Lock/Lift 161 Door Lock2026-01-05 06:30:01

Operations Head negotiating terms for Elevators Spare Parts/Elevator 161 Contactor Door Lock/Lift 161 Door Lock2026-01-05 06:30:01 Purchasing Director placed an order for Elevators Parts Door Contactor/300P Touch Point10 hours ago

Purchasing Director placed an order for Elevators Parts Door Contactor/300P Touch Point10 hours ago Lead Purchaser requested a quote for hot sale elevator ac110v magnetic contactor2026-01-01 15:57:13

Lead Purchaser requested a quote for hot sale elevator ac110v magnetic contactor2026-01-01 15:57:13 Operations Head submitted an RFQ for Elevators Parts Spare Door Contactor/300P Touch Point2026-01-03 17:45:25

Operations Head submitted an RFQ for Elevators Parts Spare Door Contactor/300P Touch Point2026-01-03 17:45:25 Business Owner negotiating terms for high-quality 220V new air conditioner ac elevator parts high power contactor 18A 80A2026-01-01 20:59:13

Business Owner negotiating terms for high-quality 220V new air conditioner ac elevator parts high power contactor 18A 80A2026-01-01 20:59:13 Purchaser requested specs for Albright DC88B 24VDC 100A Reversing Contactor/ Electricity Contactor for Electric Vehicle, Forklift Circuit Elevator Parts2026-01-04 15:59:29

Purchaser requested specs for Albright DC88B 24VDC 100A Reversing Contactor/ Electricity Contactor for Electric Vehicle, Forklift Circuit Elevator Parts2026-01-04 15:59:29 Procurement Lead inquired about Elevators Spare Parts/S8 Contactor/Door Lock Contact2026-01-02 21:58:23

Procurement Lead inquired about Elevators Spare Parts/S8 Contactor/Door Lock Contact2026-01-02 21:58:23 Buyer placed an order for best price 220v magnetic contactor for elevator parts2026-01-02 00:52:59

Buyer placed an order for best price 220v magnetic contactor for elevator parts2026-01-02 00:52:59 ELEVATOR RELAY CONTACTOR 3RT1526-1BM40US$ 1 - 10MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: ELEVATOR RELAY CONTACTOR 3RT1526-1BM40Model Number: ELEVATOR RELAY CONTACTOR 3RT1526-1BM40Nantong Jinta Elevator Components Co., Ltd.

ELEVATOR RELAY CONTACTOR 3RT1526-1BM40US$ 1 - 10MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: ELEVATOR RELAY CONTACTOR 3RT1526-1BM40Model Number: ELEVATOR RELAY CONTACTOR 3RT1526-1BM40Nantong Jinta Elevator Components Co., Ltd. Elevator Door Contactor AZ-05US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: AZ-05Nantong Jinta Elevator Components Co., Ltd.

Elevator Door Contactor AZ-05US$ 0.1 - 1,000MOQ: 1 PiecePlace of Origin: Jiangsu, ChinaBrand Name: BIMOREModel Number: AZ-05Nantong Jinta Elevator Components Co., Ltd. 24V Magnetic Contactor Relay for ElevatorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: GMR-4DBeijing Yunchang Elevator Co., Ltd.

24V Magnetic Contactor Relay for ElevatorNegotiableMOQ: 1 PieceBrand Name: XinAoModel Number: GMR-4DBeijing Yunchang Elevator Co., Ltd. Sales Fuji Elevator dc ContactorUS$ 10 - 65MOQ: 20 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: ChenfModel Number: ZJW100Electricity Type: ACYueqing Chenf Electric Co., Ltd.

Sales Fuji Elevator dc ContactorUS$ 10 - 65MOQ: 20 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: ChenfModel Number: ZJW100Electricity Type: ACYueqing Chenf Electric Co., Ltd. Hot Sale Elevator Parts 2NO2NC Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: SC-N2Beijing Yunchang Elevator Co., Ltd.

Hot Sale Elevator Parts 2NO2NC Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: SC-N2Beijing Yunchang Elevator Co., Ltd. Lowest Price Elevator Electrical ac Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: GMC-22Beijing Yunchang Elevator Co., Ltd.

Lowest Price Elevator Electrical ac Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: GMC-22Beijing Yunchang Elevator Co., Ltd. Elevator Suitable Price dc Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: CZT-10Beijing Yunchang Elevator Co., Ltd.

Elevator Suitable Price dc Magnetic ContactorNegotiableMOQ: 1 PiecePlace of Origin: Beijing, ChinaBrand Name: XinAoModel Number: CZT-10Beijing Yunchang Elevator Co., Ltd.