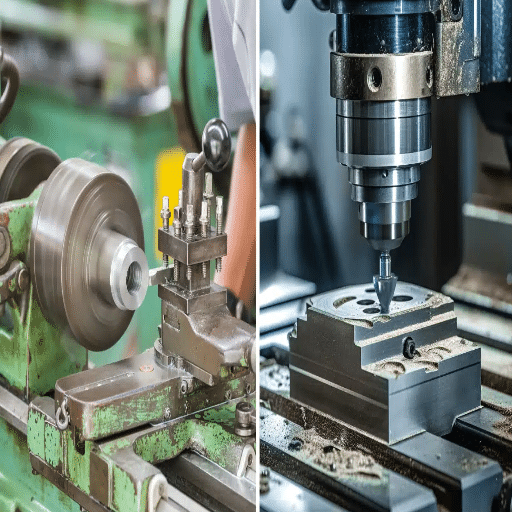

Scheduled upkeep serves as the backbone of any CNC lathe or mill machine’s upkeep. These tools are the lifeblood of industry, as they provide unrivaled modern capabilities in precision, speed, and efficiency. Neglecting upkeep results in faltering performance, costly downtime, reduced productivity, and expensive repairs. This blog aims to provide you with tips to prolong the peak performance of your CNC machine, empowering you with actionable methods from daily checks to long-term maintenance strategies. Whether you’re a seasoned operator or new to the industry, these takeaways will equip you with the knowledge needed to achieve optimal machine health and production quality. Arm yourself with critical knowledge and stay tuned as we break down the essential steps to CNC machine maintenance success. Click here to read more!

What Are the Best Maintenance Tips for CNC Lathes?

How to Clean Your CNC Lathe Effectively?

The CNC lathe’s precision, performance, and lifespan depend on proper cleaning. First, clear the machine’s surfaces of all chips and debris, as the waste material can also interfere with the functioning of mechanical components. Use a brush or compressed air to clean small areas in tight spaces, being careful not to damage more delicate areas. Pay special attention to the tool holder and chuck since these parts tend to accumulate residue during normal machining operations.

Use an elevose percussion polish for the lubricated parts that require it, and do so in a non-intrusive fashion. Scrub away grease particles on the CNC lathe, avoiding any damage that could occur from scrubbing on the metal surfaces. Standardly, remove any grime found on the coolant tank and partake in regular flushing of it, as stale coolant can result in inaccuracy while the lathe is in use and lead to inefficient machining.

Carrying out simple housekeeping tasks with the machine daily and more advanced cleaning on a weekly or monthly basis will reduce long-term deterioration and wear on the machine. After these actions have been put into motion and further developed, confidence can be raised in reduced downtime, cleaner lathe CNC downtime, and improved metering on feed, which warrants optimal active machine condition metric performance.

What Lubrication Is Best for CNC Lathes?

Choosing the proper lubrication for CNC lathes is critical for their operations, accuracy, and durability. The correct grade of lubricant helps decrease friction, lowers the heat produced, and protects vital parts from harm caused by moving parts. Routine upkeep helps CNC lathes perform better, which includes using lubricants specifically designed for sliding surfaces, such as way oil and spindle oil, on the spindle bearings.

Also referred to as slideway lubricants, way oil serves as slideway and bearing grease mounted on lathes. It is used to guard metal sections of vertical lathes against rust, striations, and wear. In filthy environments, lubricating conditions need to be maintained, and therefore, they must be applied to machine surfaces. Furthermore, rotary components that are very mobile need adequate thermal balancing alongside lower vibrations, so as not to affect machining accuracy and noise.

In contemporary lathes, oil is supplied automatically, reducing wastage and ensuring precision measurements. Machines should have periodic checks to determine their reliable level and maintain proper lubricant quality. Sticking to suggested guidelines maintains performance pace, adds to the CNC attribution lifespan, and improves efficiency and granularity of CNC lathe parts.

When Is It Best To Maintain A CNC Lathe?

The maintenance schedule of a CNC lathe is influenced by both the usage rate and the operating conditions. The recommendations given by the manufacturer also play a vital role. Often, maintenance activities are divided into four parts: daily, weekly, monthly, and yearly.

Daily maintenance: The operator is responsible for checking, cleaning, and lubricating the CNC lathe and all of its parts. They must remove all visible chips and debris from the area around the machine. The operator is also responsible for visually inspecting the machine for damage.

Weekly maintenance: Employees need to check for signs of wear and tear on the belts, filters, and critical seals every week. The weekly maintenance also includes checking the torque of critical bolts and connections, which guarantees system safety.

Monthly maintenance: There is a list of specific things that need to be taken care of every month. Check the alignment of the spindles, electrical connections of the CNC lathe machines, and any additional internal components. It is best practice to use this time to replace any worn wipers or seals as well, so they can function effectively and protect against dirt and other contaminants.

Annual Maintenance: Each year, it is essential to conduct a thorough evaluation. In most cases, this means servicing the machine, emptying the oil and coolant, replacing them with new ones, and a technician checking the electronics and mechanical parts in depth. At this level, preventative maintenance could save a lot of time and money by noticing possible problems before they arise.

If businesses follow these measures and adapt them to the CNC lathe’s usage patterns, there will be a remarkable increase in the machine’s lifespan and precision.

How Can You Maintain a CNC Mill for Optimal Performance?

What Is The Function Of A Lacquer Thinner?

When it comes to CNC laser cutting or any type of CNC machine operation, the tools employed can undergo wear and tear due to frequent use. So, one must keep a lookout for even the most minor discrepancies while operating CNC mills, because it can cost a lot of time and damage. During a CNC mill operation, while carrying out several cuts, the vibration of the machine or any uncharacteristic noise may be able to tell you precisely what is going wrong within the machine.

Any diamond-like cuts, visible due to repetitive wear on plow tools, can also indicate problems. Other issues might stem from seized axis on CNC lathes which could be caused by over tensioned ball screws. Spindle motors suffering will have their bearings attached, leading the machine to become far less performant. There is also the possibility that ball screws are malfunctioning, causing a dome like effect on the plate where they are hdden. The main problem will always be viewed from a different angle, often believed to be the “root of all problems.” Noticing a degraded speed after a CNC mill process or an unusual increase in scrap count throughout the entire process, without any change to baseline performance, suggests that routine maintenance might be overdue.

How to Change the Speed and RPM on a CNC Milling Machine

Like most machines, a CNC mill has a specific speed and RPM (revolutions per minute) that need to be set to optimize its functions. For machining processes, these settings need to change based on the material being worked on and the cutting conditions. Earlier, I mentioned that it is critical to know what material you are working with. When setting the speed, heavier and more complex materials, such as steel and titanium, usually require lower RPMs. This is because precision is paramount with them. On the other hand, aluminum and certain plastics are softer and more forgiving, making them ideal for high RPM settings.

These days, adjusting a CNC milling machine involves a lot of automation and specialized panels. Usually, you just have to input your desired spindle RPM into the respective panel, and the machine will take care of the rest. Be sure to familiarize yourself with CNC programming, as it is beneficial for creating tailored solutions based on formulas like this one: RPM = (Cutting Speed × 4) / Tool diameter. Cutting speed, set by the tool and material, and reference charts provided by tool manufacturers are also crucial for precision.

The new generation of CNC machines has added controls that allow the operators to adjust the RPM settings while the machine is running. This is determined by how the machining performance is visually observed. Furthermore, other features such as adaptive feed control allow speed changes to be retuned to avoid tool blunting or other catastrophic events, shifting automatically. Constant monitoring of spindle load and vibration using embedded sensors also allows for proper tuning to ensure dependable efficiency during milling operations.

What Cleaning Supplies Are Needed for CNC Mill Maintenance?

Cleaning procedures performed on a CNC mill require a complete set of cleaning materials if the machine is to stay in optimal working condition. Firstly, labeled, advanced, non-absorbing cleaning brushes and soft cloths for scouring overhead and cleaning metal shavings and debris from the delicate surfaces of the machine are vital components because they prevent scratching of machine surfaces. More advanced degreasers and cleaning agents are also essential due to their efficiency in disintegrating oils and cutting fluids from workpieces that are usually idle on the CNC machine. For the difficult-to-reach areas, chips and dust on the intricate components can be cleared using air cans or air guns, which are more advanced.

Moreover, using correct lint-free wipes ensures that no residues are left on surfaces, which can contaminate sensitive items. Coolant tank cleaners are manufactured to clean and disinfect the coolant system by removing any buildup and microbial growth that may hinder performance or cause unpleasant odors. It is crucial to have solvent-resistant gloves and other forms of protective clothing to safeguard the operators during the maintenance activities. Keeping these materials on hand and following an organized and routine cleaning plan will be beneficial in reducing downtime and increasing the accuracy and dependability of CNC mills.

What Are the Key Differences in Maintenance Between CNC Lathes and CNC Mills?

Lathes and Mills: How Does Maintenance Frequency Differ?

According to the given roles for CNC lathes and CNC mills, along with their mechanics, the maintenance frequency differs for each type of machine. CNC lathes, for instance, primarily work on symmetrical, rotational parts. Their active working surfaces consist of spindle bearings and their chucks. This means that wear and tear is almost always guaranteed. Hence, lathes capitalize on bearing and chuck lubrication and alignment at strategically dependent intervals based on material hardness and production intensity.

CNC mills can tackle a wide range of machining tasks, including complex geometries and multi-axis movements. This complexity not only translates to increased machining capabilities but also more routine cleaning due to chip buildup and coolant contamination, similar to CNC lathe counterparts. The intricate movements of the mill table, as well as tool changers, also lead to misalignment that requires lubricant realignment focus and precise cuts orientation.

Both machines undergo daily cleanliness and lubrication checks. While they are not a servicing burden, lathes tend to be less demanding in terms of preventive maintenance. Mills that are not appropriately maintained suffer from degradation in precision. Lathes, more than mills, require servicing in environments marked with high abrasive wear materials. These work environments, marked by heavy production loads or abrasive materials, will need to adjust their maintenance schedule proactively. This ensures optimal performance while eliminating the risk of unexpected downtime.

What Specific Tools Are Required For Each Machine?

Tools for lathes and mills may differ based on the task at hand. However, some tools are critical for each machine. For lathes, cutting and facing tools such as turning inserts, boring bars, and parting tools are necessary. Live centers and chuck jaws also help restrain and grip the workpiece, allowing for proper alignment while it rotates.

Milling machines require distinct tools for the various types of material removal techniques. End mills, face mills, and ball-nose cutters are vital for cutting and profiling work in milling. Tool holders use collets and arbors to secure cutting tools. Additional specialized accessories such as clamping kits, angle plates, and indexing heads are often needed to provide precise spatial dimensions while machining complex geometries. Advanced digital indicators and calibration equipment are tools that help keep both machines in top shape in terms of accuracy. In any shop, maintaining an organized tool inventory will significantly reduce downtime and increase productivity.

What Maintenance Practices Ensure Precision in CNC Machines?

How to Calibrate Your CNC Machine for Proper Cuts

Maintaining the accuracy and quality of a CNC machine’s output requires proper calibration. Calibration has many steps, the first of which is checking the physical details of the CNC machine. The first step is to check the levelness of the machine bed using a precision spirit or a laser level. Inaccurate cuts can result from machine beds that are not perfectly aligned.

After that check if the internal parts of the machine that have moving axes, the X, Y, and Z are aligned. Place a machining square or dial indicator below the axes to confirm that each axis allows for relative motion at a 90-degree angle to the other. If that is not the case, the axis offsets will need to be adjusted through the machine’s controller software.

Moreover, the spindle needs to be calibrated too, to confirm it’s not running out of control. Without correct spindle alignment, the machine will almost certainly malfunction, resulting in poor, excessive over-tolerance. The runout of the spindle needs to be double-checked using a spindle meter. If any discrepancies are found, they must be corrected by adjusting the clamps or repositioning the spindle.

The accuracy of the tool’s cut length and position is equally significant as all the previous steps. This guarantees that during the operation, the cutting implements will remain at the desired depth and contour. Correctly setting the tool or touch probe allows you to offset the tool and ensures it is set correctly.

Finally, assess the machine’s performance by conducting a test cut and measuring the resulting dimensions with highly accurate tools, such as calipers or micrometers. Measuring these dimensions against the programmed values will determine whether further modification is needed. Calibration of CNC machines enhances precision, reduces waste and maintenance costs, and extends the equipment’s longevity.

In what ways does the spindle affect the CNC machine maintenance?

The spindle is an integral part of any CNC machine, as it directly impacts machining quality, accuracy, and other CNC machine functions. As the active element that rotates the cutting tools, the spindle must turn at different speeds to meet the varying requirements of materials and the cuts made on them. Operating the spindle as a standalone attachment without regular maintenance can result in damage, inconsistent rotational reliability, vibration, and wear that affect cutting accuracy.

Spindle maintenance revolves around adequate lubrication, checking for excessive wear and overheating that can degrade the tools and workpieces. Accumulation of debris within the spindle bore and imbalance of tool holders also add to the degree of runout and therefore need to be addressed to improve dependability. Manufacturers can improve reliability and reduce operational costs by maintaining the productivity of the equipment used for machining.

How to Troubleshoot Common CNC Machine Maintenance Issues?

What Are The Common CNC Lathe Issues And Solutions?

Just like in everyday activities, solving CNC lathe issues for me starts with pinpointing the core issues. In this regard, user-documented complaints are a good starting point. It is common to encounter loss of precision or consistent quality of parts due to misalignment of machine components. In these cases, my first approach is to check the machine’s axes and adjust them if needed, then further verify that all parts are operationally aligned within the machine. Indeed, alignment can always be checked using a dial indicator or other precision measuring tools. After I confirm that proper alignment is confirmed through recalibrated settings, I will run a sample workpiece to verify if the problem is indeed solved.

Still, onboard equipment vibration due to parts being machined is a common problem. This phenomenon can have adverse effects on both the quality of the part and its surface finish. This, in turn, affects the precision of the machining process. The majority of mismatching surface finishes on the cylindrical surfaces of rotational body parts result from imbalanced tool holders and worn spindle bearings. The first avenue for resolving the issue is to check the tool holders for balance and damage. Should that not yield the desired outcome, the next focus converges on the spindle focus and its bearings, which will require repair or replacement. Moreover, maintaining minimal stress on the system also proves effective in reducing vibrations. For example, optimizing the cutting parameters for the material currently being worked on solves that problem.

Lastly, overheating is one of the most common issues, as it can slow down the CNC machine and also increase the rate of tool wear. To remedy overheating, I ensure proper coolant levels and lubrication systems are in place. Overheating problems can usually be solved by cleaning the coolant lines and unclogging filters. Maintaining and periodically inspecting the lubrication and cooling systems ensures the CNC lathe remains optimally efficient and prevents further issues from developing. With these methods, CNC lathe problems can, in my experience, be resolved quickly and effectively.

How to Contend with a Faulty CNC Mill?

Identifying the cause is the first step in fixing the cnc mill. Once the problem is identified, several factors need to be considered, including part misalignment, spindle issues, tool sharpening techniques, and software problems caused by third-party applications. The first step is a thorough diagnosis, and a visual one at that, where looking for chipped tools and loose parts, as well as rotary table alignment, should be prioritized. In many instances, simple tasks such as replacing the damaged tools or tightening loose bolts and screws is all that is required to get the job done. The attention given to the machinery’s error codes is equally as important as paying attention to the diagnostics of the machine.

When the problem isn’t apparent, I look into the software and the various controls of the machine. It’s essential to check for mistakes in the G-code or toolpath programming, as they can cause problems. I make sure to check the logical flow of the program step by step. In troubleshooting, problems can be dealt with more readily if they are broken down into simplified parts, which, in turn, allows for more focused and broader testing. Sometimes, simply recalibrating the machine or resetting its control unit resolves issues that stem from software or communication problems.

Preventive maintenance is just as essential as any other metric when it comes to reducing CNC mill breakdowns or malfunctions. My standard procedure includes cleaning and lubricating all mobile components, performing visual checks for belt and spindle wear, and verifying the status of the sensors and limit switches. These steps, along with being proactive and supportive, allow me to not only significantly reduce CNC mill downtime but also increase its longevity, thereby maintaining production schedules and efficiently meeting targets.

What Tools Help Diagnose CNC Machine Issues?

Specialized tools and systematic approaches are used in tandem when diagnosing CNC machine issues. In my situation, a combination of hardware tools and software tools works best for problem identification and remediation. A digital multimeter is one tool that I can’t go without; it helps check electrical continuity, measure voltage, and inspect components like motors and power supplies. Without a doubt, this device helps diagnose electrical failures that are likely to cause unexpected breakdowns. In addition, I use dial indicators and test bars to measure machine alignment and check for deviations in the movement of the axes, ensuring that operations are executed to a high degree of precision.

Finding errors and machine optimization rely heavily on software tools. Integrated diagnostic software identifies issues within CNC system components and performs advanced diagnostics using log files. Moreover, vibration analysis tools allow me to pinpoint problems with misalignment, imbalance, or other bearing failures before they can develop into critical ones. Most importantly, I make it a priority to keep learning about new technologies and the latest diagnostic methods, which helps me widen the range of challenges I can address.

Having these instruments, along with a clear understanding of the machine’s manual and schematics, enables me to troubleshoot and resolve issues with ease. I also take the time to document persistent problems and share my observations with teammates, building a knowledge base that simplifies future repairs and maintenance. This not only reduces downtime but also ensures that the CNC machine continues to perform reliably at optimal levels.

Frequently Asked Questions (FAQs)

Q: What are some essential maintenance tips for CNC lathes and mills?

A: Furthermore, maintenance of CNC lathe and mill machines should include regular checking and replacement of worn-out parts, cleaning the machines of chips and other debris, lubricating all moving parts, and ensuring that all electrical connections are tight. This will improve the life of your machine tools.

Q: How often should I perform maintenance on my CNC machine tool?

A: It differs in regularity depending on how the machine is used, but a general recommendation is to clean, check, and maintain the machine at intervals of every 100 working hours or once a month. This involves checking the motor, lubricating the moving parts of the machine, and cleaning the surrounding area where the machine is located.

Q: What should I do if my CNC lathe machine shows signs of wear?

A: Wearing signs such as strange sounds or lack of sharpness should be dealt with immediately once it is noticed by stopping the use of the machine right away. Inspect further for broken parts and replace the damaged ones. Additionally, refer to the manual for possible troubleshooting steps. Preventive wear monitoring can reduce major breakdowns.

Q: Are there any specific maintenance tools I should have in my garage or workshop?

A: Yes. Torque wrenches, cleaning brushes, lubricant applicators, and precision measuring tools are some essential pieces of equipment for maintenance, and they should be kept in the shop. In addition, having multiple tool holders and shank tools can heighten the efficiency of CNC machine maintenance.

Q: How can I improve the efficiency of my CNC milling machines?

A: Improvement of CNC milling machine performance begins with commissioning and accurate calibration of the machines, clearing chips from the CNC machines to prevent performance deterioration, and regular cleaning of the machines. Additionally, CNC processes and automation can be integrated into CNC operations to boost shop productivity.

Q: What type of lubrication is best for CNC lathe and mill maintenance?

A: Lubricants should be tailored to specific CNC lathes and mills; use lubricants specified by the manufacturer. Oil and grease at higher speeds are effective in lubricating restive moving parts and ensuring they operate seamlessly.

Q: Can I perform maintenance on my CNC mini milling machine myself?

A: Certainly, cleaning and lubrication are the majority of the maintenance procedures a user can carry out. At the same time, for specialized repairs not covered by routine maintenance, it is best to have the machine inspected by a technician or refer to the user manual for adequate instructions.

Q: What should I consider when comparing different CNC turning and milling machines?

A: Think about the kinds of materials you will be using, the level of detail and flexibility needed for your work, and what each machine offers. Also, consider the machine’s size and horsepower (hp) in addition to the type of tool holders and other accessories that can be used.

Q: How does chip management affect the maintenance of CNC machines?

A: Chip management is essential as too many chips can cause overheating, loss of accuracy, and damage to parts. Having a well-designed chip removal process and good housekeeping practices can dramatically increase the effectiveness and durability of your machines.