Фильтры

Тип

Применяемый материал

Материальные возможности

Поддерживаемые графические форматы

Состояние

Предоставляется послепродажное обслуживание

-

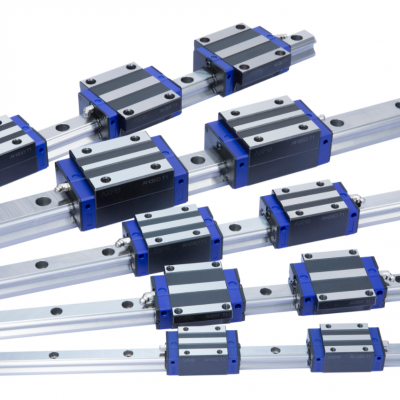

MGN7H HIWIN линейный ползун и MGNR7 миниатюрный линейный направляющийДоговороспособныйMOQ: 1 PieceНазвание бренда: ALMМесто производства: ChinaALM Intelligent Technology Suzhou Co.,Limited

MGN7H HIWIN линейный ползун и MGNR7 миниатюрный линейный направляющийДоговороспособныйMOQ: 1 PieceНазвание бренда: ALMМесто производства: ChinaALM Intelligent Technology Suzhou Co.,Limited -

Профили из пластика, полученные экструзией и инжекционным способом, Обработка экструзионных профилей из пластика, Завод пластиковых линейных направляющих, Инжекционные пластиковые изделияДоговороспособныйMOQ: 1 PieceНазвание бренда: RitengМесто производства: ChinaDongguan Riteng Industry Co.,Limited

Профили из пластика, полученные экструзией и инжекционным способом, Обработка экструзионных профилей из пластика, Завод пластиковых линейных направляющих, Инжекционные пластиковые изделияДоговороспособныйMOQ: 1 PieceНазвание бренда: RitengМесто производства: ChinaDongguan Riteng Industry Co.,Limited -

Линейный направляющий рельсДоговороспособныйMOQ: 1 PieceDachang Machinery Equipment Manufacturing Co., Ltd.

Линейный направляющий рельсДоговороспособныйMOQ: 1 PieceDachang Machinery Equipment Manufacturing Co., Ltd. -

Умный поиск источников

1ИскатьВыбирайте поставщиков с проверенными платформой значками для надежного статуса2Проверить сертификатыПроверьте сертификаты поставщиков (ISO, CE и др.) на соответствие3Сначала тестирование образцовВсегда тестируйте образцы продукции перед крупными заказами4Посетите фабрикиПроводите выездные аудиты для проверки производства5Условия оплатыИспользуйте эскроу-услуги для высокоценных сделок6Четкость контрактаОпределите штрафные санкции за задержки/отклонения от спецификаций в контрактах -

7-15 Линейный направляющий MGN15C Миниатюрные направляющие рельсы для автоматизацииUS$ 4 - 8MOQ: 1 PieceНазвание бренда: 7-15 Линейный направляющий MGN15C Миниатюрные направляющие рельсы для автоматикиМесто производства: ChinaМодельный номер: MGN15CДлина направляющей: 600 ммLongzhichuang Co.,Ltd

7-15 Линейный направляющий MGN15C Миниатюрные направляющие рельсы для автоматизацииUS$ 4 - 8MOQ: 1 PieceНазвание бренда: 7-15 Линейный направляющий MGN15C Миниатюрные направляющие рельсы для автоматикиМесто производства: ChinaМодельный номер: MGN15CДлина направляющей: 600 ммLongzhichuang Co.,Ltd -

Средний ЧПУ токарный станок, токарный станок для металла, промышленный станок, ЧПУ для обработки металлаДоговороспособныйMOQ: 1 SetНазвание бренда: YORNEWМесто производства: ChinaМодельный номер: CK250Тип: Токарно-револьверный центрYornew Automation Equipment Co., Ltd.

Средний ЧПУ токарный станок, токарный станок для металла, промышленный станок, ЧПУ для обработки металлаДоговороспособныйMOQ: 1 SetНазвание бренда: YORNEWМесто производства: ChinaМодельный номер: CK250Тип: Токарно-револьверный центрYornew Automation Equipment Co., Ltd. -

LM линейные шарикоподшипники для линейных направляющихДоговороспособныйMOQ: 10 PiecesНазвание бренда: RICOCNCМесто производства: ChinaМодельный номер: ЛМ линейные шарикоподшипники с роликамиSuzhou Rico Machinery Co., Ltd

LM линейные шарикоподшипники для линейных направляющихДоговороспособныйMOQ: 10 PiecesНазвание бренда: RICOCNCМесто производства: ChinaМодельный номер: ЛМ линейные шарикоподшипники с роликамиSuzhou Rico Machinery Co., Ltd -

Подшипники из УВМПЭ для криволинейных рельсов, цепь направляющая УВМПЭUS$ 1 - 1MOQ: 500 KilogramsНазвание бренда: XINXINGМесто производства: Shandong, ChinaМодельный номер: xx-2448, 4.5-9 millionМатериал: ПЭShandong Ningjin Xinxing Chemical Co,ltd.

Подшипники из УВМПЭ для криволинейных рельсов, цепь направляющая УВМПЭUS$ 1 - 1MOQ: 500 KilogramsНазвание бренда: XINXINGМесто производства: Shandong, ChinaМодельный номер: xx-2448, 4.5-9 millionМатериал: ПЭShandong Ningjin Xinxing Chemical Co,ltd. -

MK-8-4040S 4040 профиль из алюминия с Т-образным пазом для линейного направляющего рельсаUS$ 3.3 - 3.7MOQ: 100 KilogramsНазвание бренда: MK-8-4040S 4040 Стружечная линейная направляющая алюминиевого профиля с Т-образным пазом для ЧПУ. Цена заводаМесто производства: ChinaМодельный номер: MK-8-4040SФорма: КвадратныйShanghai Meike Aluminum Products Co., Ltd.

MK-8-4040S 4040 профиль из алюминия с Т-образным пазом для линейного направляющего рельсаUS$ 3.3 - 3.7MOQ: 100 KilogramsНазвание бренда: MK-8-4040S 4040 Стружечная линейная направляющая алюминиевого профиля с Т-образным пазом для ЧПУ. Цена заводаМесто производства: ChinaМодельный номер: MK-8-4040SФорма: КвадратныйShanghai Meike Aluminum Products Co., Ltd. -

TCK36A Металлический станок с наклонной станиной и линейными направляющимиUS$ 15800 - 35000MOQ: 1 SetНазвание бренда: LuzhongМесто производства: ChinaМодельный номер: TCK36AТип: ГоризонтальныйShandong Luzhong Machine Tool CO., LTD

TCK36A Металлический станок с наклонной станиной и линейными направляющимиUS$ 15800 - 35000MOQ: 1 SetНазвание бренда: LuzhongМесто производства: ChinaМодельный номер: TCK36AТип: ГоризонтальныйShandong Luzhong Machine Tool CO., LTD -

Связанные поиски

-

Дисковый тормоз воздушного трения для вращающейся платформыUS$ 50 - 100MOQ: 1 SetНазвание бренда: Handong HDМесто производства: ChinaМодельный номер: DBF-8, DBF-10, DBF-15Shanghai Handong Machinery Technology Co., Ltd

Дисковый тормоз воздушного трения для вращающейся платформыUS$ 50 - 100MOQ: 1 SetНазвание бренда: Handong HDМесто производства: ChinaМодельный номер: DBF-8, DBF-10, DBF-15Shanghai Handong Machinery Technology Co., Ltd -

Линейные направляющие THK с подвижными опорамиUS$ 1 - 10000MOQ: 1 PieceНазвание бренда: THKМесто производства: JapanМодельный номер: AДлина направляющей: 100000Beijing Zhuao Science And Technology Co., Ltd.

Линейные направляющие THK с подвижными опорамиUS$ 1 - 10000MOQ: 1 PieceНазвание бренда: THKМесто производства: JapanМодельный номер: AДлина направляющей: 100000Beijing Zhuao Science And Technology Co., Ltd. -

Нанесённая износостойкая линейная направляющая из HDPE, пластиковая линейная направляющаяUS$ 2.2 - 3.5MOQ: 100 KilogramsНазвание бренда: XinjiangМесто производства: ChinaМодельный номер: Xj45HGNingjin Xinjiang Chemical Co.,Ltd

Нанесённая износостойкая линейная направляющая из HDPE, пластиковая линейная направляющаяUS$ 2.2 - 3.5MOQ: 100 KilogramsНазвание бренда: XinjiangМесто производства: ChinaМодельный номер: Xj45HGNingjin Xinjiang Chemical Co.,Ltd -

Линейная направляющая структураДоговороспособныйMOQ: 5 CartonsНазвание бренда: zengshanМесто производства: ChinaМодельный номер: Различные спецификацииСертификация: ISO9001Hebei Zengshan Intelligent Science And Technology Co., Ltd

Линейная направляющая структураДоговороспособныйMOQ: 5 CartonsНазвание бренда: zengshanМесто производства: ChinaМодельный номер: Различные спецификацииСертификация: ISO9001Hebei Zengshan Intelligent Science And Technology Co., Ltd -

Линейная осьДоговороспособныйMOQ: 50 TonsНазвание бренда: GXМесто производства: ChinaТип: Стальной сплавной стерженьПрименение: Стальной инструментальный брусокHebei Gangxin Technology Co., Ltd

Линейная осьДоговороспособныйMOQ: 50 TonsНазвание бренда: GXМесто производства: ChinaТип: Стальной сплавной стерженьПрименение: Стальной инструментальный брусокHebei Gangxin Technology Co., Ltd -

Линейный направляющий ползунUS$ 20 - 500MOQ: 1 PieceНазвание бренда: YIAOМесто производства: ChinaМодельный номер: HGW25CCКоличество строк: Двойной рядLichuan YiAo Technology Co.,Ltd

Линейный направляющий ползунUS$ 20 - 500MOQ: 1 PieceНазвание бренда: YIAOМесто производства: ChinaМодельный номер: HGW25CCКоличество строк: Двойной рядLichuan YiAo Technology Co.,Ltd -

KNE IKO высокоточные цилиндрические роликовые линейные направляющие самосмазывающиеся направляющие MXD10-UPUS$ 100 - 999MOQ: 1 PieceНазвание бренда: IKOМесто производства: JapanShenzhen KNE Transmission Technology Co.,Ltd.

KNE IKO высокоточные цилиндрические роликовые линейные направляющие самосмазывающиеся направляющие MXD10-UPUS$ 100 - 999MOQ: 1 PieceНазвание бренда: IKOМесто производства: JapanShenzhen KNE Transmission Technology Co.,Ltd. -

Proshield РябиUS$ 10 - 45MOQ: 200 Square MetersHuizhou Oakio Plastic Wood Building Materials Co.,Ltd

Proshield РябиUS$ 10 - 45MOQ: 200 Square MetersHuizhou Oakio Plastic Wood Building Materials Co.,Ltd -

Эффективная длина. Железнодорожный числовенно-контролируемый осьевой шариковый винт с линейным направляющим ползунка. Модуль движения для гравировки.US$ 50 - 200MOQ: 1 SetНазвание бренда: ScrewtechМесто производства: ChinaМодельный номер: RXS60Длина направляющей: 50 мм - 1000 ммScrew Technology Co.,ltd

Эффективная длина. Железнодорожный числовенно-контролируемый осьевой шариковый винт с линейным направляющим ползунка. Модуль движения для гравировки.US$ 50 - 200MOQ: 1 SetНазвание бренда: ScrewtechМесто производства: ChinaМодельный номер: RXS60Длина направляющей: 50 мм - 1000 ммScrew Technology Co.,ltd -

Активность глобальных покупателей

Координатор по импорту осуществляет закупку 7-15 Linear Guide MGN9C Miniature Guide Rails For Automation2025-11-15 01:05:37

Координатор по импорту осуществляет закупку 7-15 Linear Guide MGN9C Miniature Guide Rails For Automation2025-11-15 01:05:37 Ведущий покупатель поинтересовался HGR30 OEM Long Life 600mm Linear Guide Rail Bearing18 hours ago

Ведущий покупатель поинтересовался HGR30 OEM Long Life 600mm Linear Guide Rail Bearing18 hours ago Руководитель отдела закупок поинтересовался OEM Flange Block Linear Guide Rail Hgw15 L570mm for CNC Machine2025-11-18 05:02:44

Руководитель отдела закупок поинтересовался OEM Flange Block Linear Guide Rail Hgw15 L570mm for CNC Machine2025-11-18 05:02:44 Владелец бизнеса поинтересовался HGW15 Hot Sale High Quality 1000 mm Spare Parts Linear Guide Rail Bearing2025-11-15 20:59:41

Владелец бизнеса поинтересовался HGW15 Hot Sale High Quality 1000 mm Spare Parts Linear Guide Rail Bearing2025-11-15 20:59:41 Руководитель отдела закупок проверенные сертификаты для China Factory 15mm width linear guide rail with slide block no flange HGR152025-11-17 07:29:55

Руководитель отдела закупок проверенные сертификаты для China Factory 15mm width linear guide rail with slide block no flange HGR152025-11-17 07:29:55 Специалист по закупкам осуществляет закупку SBR20 OEM 20mm CNC Round Aluminum Shaft Linear Guide Rail2025-11-14 05:37:40

Специалист по закупкам осуществляет закупку SBR20 OEM 20mm CNC Round Aluminum Shaft Linear Guide Rail2025-11-14 05:37:40 -

Станок с ЧПУ с линейной направляющей H36US$ 1 - 2MOQ: 1 PieceНазвание бренда: LUZHONGМесто производства: ChinaСертификация: CE,SONCAP,EAC,SGS,TUV,BVСостояние: НовыйTengzhou Luzhong Machine Tool Co., Ltd

Станок с ЧПУ с линейной направляющей H36US$ 1 - 2MOQ: 1 PieceНазвание бренда: LUZHONGМесто производства: ChinaСертификация: CE,SONCAP,EAC,SGS,TUV,BVСостояние: НовыйTengzhou Luzhong Machine Tool Co., Ltd -

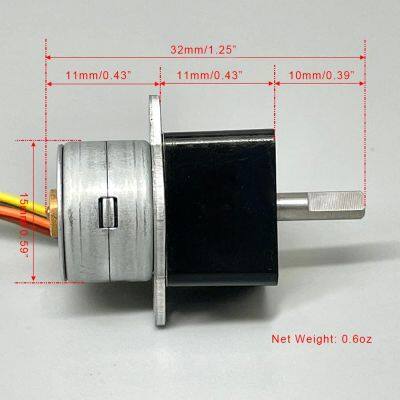

6В 12В 15 мм Шаговый двигатель постоянного магнита GA12-15BY с редукторомUS$ 5.3 - 5.8MOQ: 100 PiecesНазвание бренда: KESHUOМесто производства: ChinaМодельный номер: GM12-15BYПостгарантийное обслуживание предоставляется: Не предоставляется сервис за рубежомShenzhen Keshuo Motor Co., Ltd

6В 12В 15 мм Шаговый двигатель постоянного магнита GA12-15BY с редукторомUS$ 5.3 - 5.8MOQ: 100 PiecesНазвание бренда: KESHUOМесто производства: ChinaМодельный номер: GM12-15BYПостгарантийное обслуживание предоставляется: Не предоставляется сервис за рубежомShenzhen Keshuo Motor Co., Ltd -

thk подшипникДоговороспособныйMOQ: 1 BagНазвание бренда: thkМодельный номер: A2CДиаметр отверстия: ,Tianjin NSF Bearing Co.,ltd

thk подшипникДоговороспособныйMOQ: 1 BagНазвание бренда: thkМодельный номер: A2CДиаметр отверстия: ,Tianjin NSF Bearing Co.,ltd -

WON линейный направляющий рельсДоговороспособныйMOQ: 100 PiecesWonst Transmission Technology Tianjin Co., Ltd.

WON линейный направляющий рельсДоговороспособныйMOQ: 100 PiecesWonst Transmission Technology Tianjin Co., Ltd. -

Прямая линейная алюминиевая штанга для подвесных шторUS$ 1.5 - 2.5MOQ: 100 MetersJinan Hengsheng New Building Materials Co., Ltd.

Прямая линейная алюминиевая штанга для подвесных шторUS$ 1.5 - 2.5MOQ: 100 MetersJinan Hengsheng New Building Materials Co., Ltd.