High-capacity Innovative Automated Bellows Production Line

Plastic PVC/PP/PE Single Wall Corrugated Pipe Extrusion/Production Line

Technical parameters

| Pipe diameter range(mm) | 4.5-9 | 9-32 | 32-50 |

| Main machine model | SJ-30 | SJ-45 | SJ-65 |

| Main machine l/d | 30:1 | 28:1 | 30:1 |

| Production capacity kg/h | 10 | 40 | 80 |

| Main motor capacity kw | 4 | 11 | 18.5 |

| Moiding machine capacity kw | 1.1 | 1.5 | 1.5 |

| Pair of modules | 42 | 38 | 38 |

| Cooling mode | Water cooling and fan cooling | ||

| Production (m/min) | 6-10 | 8-12 | 8-15 |

| Metering mode | inductiing mode | ||

| Coiling machine mode | Motor-drivenManually-operated | ||

Remarks: all informance above is only for reference; please gather the exact data by contacting us.

Product Features

Fully Automated Operation: Designed for high-volume production, this machine requires minimal human input, reducing labor costs and increasing operational efficiency.

High Precision: The machine is engineered for precise measurements, ensuring consistent product quality across all units.

Energy Efficient: The system uses the latest in energy-saving technologies, minimizing electricity consumption while maximizing throughput.

Durable Construction: Built with high-quality materials to withstand the rigors of continuous production.

Intelligent Control System: Features advanced PLC control, making it easy to monitor and adjust settings for optimal performance.

Modular Design: The production line can be customized with different modules to meet specific production requirements.

Advantages

High Productivity: The automated system operates at a high speed, producing up to 150 bellows per hour, making it suitable for large-scale manufacturing.

Cost-Effective: Thanks to its energy-efficient design and low maintenance requirements, this system is a cost-effective solution for bellows production.

Customizable: Tailor the system to your specific needs, whether you’re producing standard or specialized bellows for various applications.

Quality Assurance: With stringent quality control measures, the machine ensures that each unit meets high industry standards.

Comprehensive Service: Zhongrui Machinery offers a full range of after-sales support, including installation assistance and troubleshooting.

Applications

The High-capacity Innovative Automated Bellows Production Line is ideal for a variety of industries:

Automotive: Manufacturing exhaust bellows and air intake bellows.

Aerospace: Production of high-performance bellows for aircraft components.

HVAC: Production of flexible bellows for heating, ventilation, and air conditioning systems.

Industrial: Manufacturing bellows for machinery, compressors, and pumps.

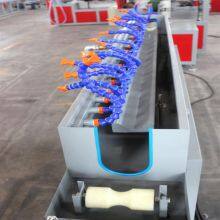

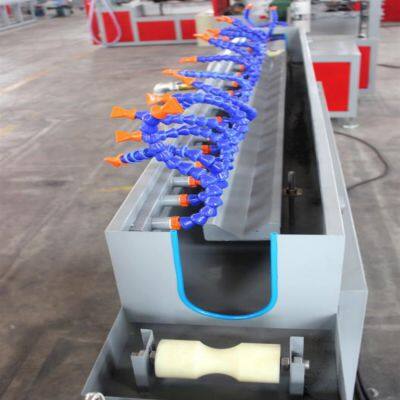

Process flow:

Dryness loader →Single screw extruder

→Die→Forming moulds→

→Double working-station winder

Performance advantage

Fast production speed: By optimizing the equipment structure and cooling system, the production speed of some production lines can reach up to 10-15 meters per minute, greatly enhancing production efficiency and meeting the demands of large-scale production.

Stable operation: The specially designed screw, mold and forming machine structure ensure strong stability of the equipment during operation, reduce downtime caused by equipment failure and guarantee the continuity of production.

Easy operation: The control system of the equipment is designed simply and is easy to operate. After a brief training, the staff can master the operation process of the equipment proficiently, reducing labor costs and operation difficulty.

High product quality: The PP/PE single-wall corrugated pipes produced feature high temperature resistance, corrosion resistance, wear resistance and high strength. The inner and outer walls of the pipe are smooth, with uniform and clear corrugations, which can meet the usage requirements in various complex environments.

Convenient specification switching: The forming modules are not connected to each other, and the operation is relatively simple when changing specifications. It can quickly adapt to the production needs of different pipe diameters and corrugation specifications, improving the universality and flexibility of the production line.

Application field

In the electrical field: It can be used as an electrical conduit to protect wires and cables from erosion by the external environment and mechanical damage, ensuring the safety and stability of power transmission.

Automotive industry: As a conduit and protective sleeve for automotive wiring, it is used to protect the internal circuits of automobiles and can effectively resist harsh environments such as vibration, friction, and high temperatures during the operation of automobiles.

Packaging food machinery: It can be used for the protection of internal circuits and pipelines of equipment, meeting the requirements of the food industry for hygiene, corrosion resistance and other aspects.

Engineering installation: In the installation of construction, municipal and other engineering projects, it is used for water supply and drainage pipes, ventilation pipes, etc. Due to its excellent corrosion resistance and strength, it can extend the service life of the pipes.

Automated instruments and meters: As line protection tubes, they provide a guarantee for the stable operation of instruments and meters, preventing the lines from being disturbed or damaged.

FAQ

Q: Are you a manufactuer or trading company?

A: We're professional manufacturer.

Q: Where is your company?

A: Our company is located in Qingdao City and it's only half an hour's drive from the airport.

Q: What's your payment term?

A: L/C, TT is all good to do.

Q: When can I get the price?

A: Once we get the specific inquiry, we can send you the price with the configuration within 3 days.

Q: If we have some other product requirements that your page don't include, can you help to supply?

A: Yes, we can customize products and services to meet your specific needs.

Q: How long is the warranty period?

A: 12 months.

Why Choose Us

Experienced Manufacturer: Zhongrui Machinery has over 20 years of experience in manufacturing high-capacity production lines.

Cutting-Edge Technology: We invest in the latest technologies to ensure our machines are reliable, efficient, and easy to operate.

Global Presence: With a presence in over 50 countries, we have a track record of delivering high-quality machinery to clients worldwide.

Comprehensive Support: From installation to ongoing technical support, our team ensures that your production line runs smoothly.

Send Inquiry to This Supplier

You May Also Like

-

PMMA Transparent Plate Production Line/PC Sheet Extrusion Machine/Plastic MachineryUS$ 150000MOQ: 1 Set

-

PMMA HIPS ABS Plastic Sheet Extrusion Machinery/Acrylic Sheet Making MachineUS$ 150000MOQ: 1 Set

-

ABS HIPS PMMA PC Sheets Boards Plates Extrusion Line Extruder MachineUS$ 150000MOQ: 1 Set

-

ABS HIPS PMMA PC Sheets Boards Plates Extrusion Line Extruder MachineUS$ 150000MOQ: 1 Set

-

ABS HIPS PMMA PC Sheets Boards Plates Extrusion Line Extruder MachineUS$ 150000MOQ: 1 Set

-

ABS HIPS PMMA PC Sheets Boards Plates Extrusion Line Extruder MachineUS$ 150000MOQ: 1 Set

-

Sj65/33 PE Grass Stone Isolation Strip Plastic Production MachineryUS$ 30000MOQ: 1 Set

-

High-capacity Steel Curtain Belt Production LineUS$ 73000 - 83000MOQ: 1 Set

-

Drainage Board Production LineUS$ 40000MOQ: 1 Set

-

PVC Imitation Marble Sheet Slab Extruder Machine Production Line/ UV Decorative Plate Production LineUS$ 64999 - 65999MOQ: 1 Set