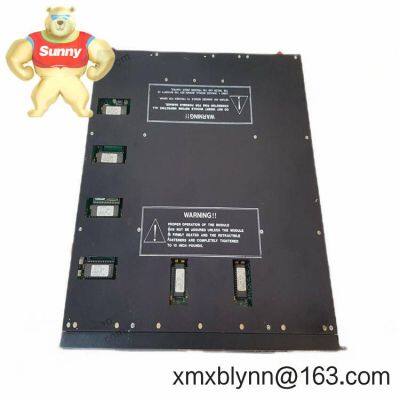

TRICONEX 3007 CPU Module: Your Industrial Safety Net for Critical Processes

Triple voting architecture – Processes identical commands across three independent CPUs. In most cases, it catches faults before operators even blink. Saw this save a chemical plant's reactor last year when two CPUs disagreed on a valve signal.

SIL 3 certified – Handles safety functions up to IEC 61511 standards. Not just paperwork; it's why inspectors rarely hassle plants using these for ESD systems.

Backward compatible – Slides right into legacy TRICON racks (1137 controllers). One refinery engineer told me swapping old 3006 modules took under 20 minutes during a night shift.

Hot-swappable – Replace failed CPUs without shutting down the whole system. Typically avoids those 3 AM emergency calls when one module hiccups.

| Parameter | Details |

|---|---|

| Brand/Model | TRICONEX 3007 (Schneider Electric legacy) |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24 VDC ±10%, 3.5A max (per rack) |

| Dimensions & Weight | 300mm W × 225mm H × 170mm D / 2.8 kg |

| Operating Temperature | -20°C to +60°C (no derating needed) |

| Communication | Modbus RTU over RS-485, TRISTATION 1131 interface |

You'll find these guarding flare stacks at LNG terminals or emergency depressurization systems in ethylene plants—places where a 0.1-second delay could trigger a cascade failure. A petrochemical client once showed me how it managed 17 redundant pressure sensors on a hydrogen reactor; in their words, "It's boring when it works, which is exactly what we want."

Let's be real—nobody buys this for "innovation." It's about avoiding $500k/hour downtime during turnaround season. The TMR design typically slashes false trips by 90% compared to single-channel systems I've seen fail. And since it talks Modbus? You won't need to rewrite all your SCADA logic. One plant manager admitted they've kept spares since 2005 because firmware updates rarely break compatibility.

Installation & Maintenance Reality CheckMount it on standard 35mm DIN rail—no fancy brackets. But here's what manuals gloss over: keep it away from VFD cabinets. I've seen harmonic noise from drives mimic fault signals. Ventilation matters too; that 60°C rating assumes 50mm clearance above/below. For maintenance? Swap the backup battery every 5 years (it's right there on the front), and blow dust out quarterly with dry air. No calibration needed—it's digital or bust.

Certifications & GuaranteesCE, UL 61508, IEC 61511 SIL 3 certified. RoHS compliant (lead-free solder since 2006 models). The warranty's straightforward: 365 days from shipment date—covers defects but not lightning strikes or coffee spills. If it's in stock (usually is), you'll get it shipped within a week via FedEx/UPS/DHL. Payment's 50% upfront, balance before dispatch. Simple.

Send Inquiry to This Supplier

You May Also Like

-

TRICONEX 3720 Analog Input Module Multiple Analog Signals Can be Collected SimultaneouslyNegotiableMOQ: 1 Bag

-

T8451 Digital Output Module Each Power Pack is Limited to 8ANegotiableMOQ: 1 Bag

-

4352B Transmission Control ModuleNegotiableMOQ: 1 Bag

-

T8448 Multifunctional Field Terminal Components Provide Precise LocationNegotiableMOQ: 1 Bag

-

TRICONEX 3009 Enhanced Main Processor (UMP) Module Improve Processor PerformanceNegotiableMOQ: 1 Bag

-

Triconex 4329 Network Communication Module Ethernet (802.3) PortNegotiableMOQ: 1 Bag

-

Triconex 3636R Automatic Control Module Supports Multiple Communication ProtocolsNegotiableMOQ: 1 Bag

-

Triconex 3625C1 Digital Output Module The Flexibility of the Control System is ImprovedNegotiableMOQ: 1 Bag

-

TRICONEX 3721 Communication Module Multiple Sensors Can be ConnectedNegotiableMOQ: 1 Bag

-

Triconex8110 Security System Framework Ensure the Safety of the Production ProcessNegotiableMOQ: 1 Bag