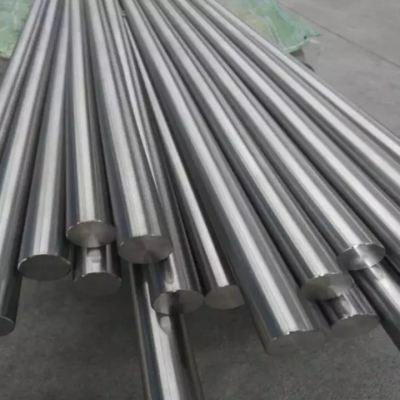

Medical Grade TA2 Pure Titanium Bar / GR2 Biocompatible Titanium Rod for Surgical Implants

Product Overview

Our Medical Grade TA2 Pure Titanium Bar, also known as GR2 Biocompatible Titanium Rod, is a high - quality product specifically designed for surgical implants. Titanium has long been recognized as an ideal material for medical applications due to its unique combination of properties. This bar is manufactured to the highest standards, ensuring its suitability for use in the demanding field of medical surgery.

Material and Surface Treatment

- Material: The bar is made of pure titanium (TA2/GR2). Titanium is well - known for its excellent biocompatibility, which means it can integrate well with the human body without causing significant immune responses or adverse reactions. This property is crucial for surgical implants as it reduces the risk of rejection and promotes faster healing.

- Surface Treatment: It features a bright rod surface treatment. This not only gives the bar an aesthetically pleasing silver color but also provides a smooth surface finish. A smooth surface is beneficial in surgical applications as it reduces the risk of tissue irritation and makes it easier to clean and sterilize the implant.

Shape and Dimensions

- Shape: The product comes in a bar shape, which is a common and versatile form for surgical implants. Bars can be easily machined and customized to fit the specific requirements of different surgical procedures. Whether it's for orthopedic surgeries, dental implants, or other medical applications, the bar shape provides a solid foundation for further processing.

- Dimensions: While specific dimensions can be customized according to the customer's needs, our manufacturing capabilities allow us to produce bars with a high degree of precision. We can ensure that the bars meet the strict dimensional tolerances required for medical use, guaranteeing a perfect fit in the surgical site.

Manufacturing Process and Quality Assurance

- Manufacturing: Our company, with a history of expertise in metal processing, uses advanced manufacturing techniques to produce these medical - grade titanium bars. We have automated production lines that cover the processing of various materials, including titanium. The bars are produced under strict quality control measures to ensure their consistency and reliability.

- Quality Assurance: We are committed to providing products that comply with international standards. Our titanium bars meet ASTM F136, a standard specifically for medical - grade titanium. In addition, we have advanced NDT (Non - Destructive Testing) services. Ultrasonic Testing (UT) to EN 10228 - 3 is used to detect internal defects as small as 0.5mm, and Magnetic Particle Testing (MT) is employed to check for surface cracks. Our testing facilities are certified by SGS and BV, ensuring the highest level of quality and safety.

Applications in Medical Field

- Orthopedic Surgeries: In orthopedics, these titanium bars can be used to create implants such as bone plates, screws, and rods. Their high strength - to - weight ratio allows them to support the body's weight while minimizing the additional stress on the bones. The biocompatibility of titanium also helps in promoting bone growth around the implant, facilitating the healing process.

- Dental Implants: For dental applications, the bars can be machined into dental implants. Titanium's ability to integrate with the jawbone (osseointegration) makes it an ideal material for long - term dental solutions. The smooth surface finish of our bars also helps in preventing the accumulation of bacteria and plaque, maintaining oral hygiene.

- Other Surgical Implants: They can also be used in other surgical fields, such as cardiovascular and neurosurgery, where the need for biocompatible and reliable materials is of utmost importance.

Company Background and Support

- Company History: Our company has evolved from an R & D - focused startup in 2003 to a global special steel solution provider. We have a rich history of developing high - quality materials for various industries, including the medical field. Over the years, we have continuously upgraded our technology and obtained important certifications such as ISO 9001:2015, API 5L, and EU PED, which demonstrate our commitment to quality and compliance.

- Expert Team: Our leadership team consists of experienced professionals. Mr. Sang Le, our CEO, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Dr. Li Wei, our Chief Metallurgist, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. Our technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring that our products are of the highest quality.

- Customer Support: We offer customized materials and value - added services for global industries. Our strategically located warehouses in Wuxi ensure rapid logistics, with a 48 - hour delivery to major Chinese ports. We are dedicated to providing excellent customer service and technical support to our international clients, helping them find the best solutions for their medical implant needs.

Send Inquiry to This Supplier

You May Also Like

-

High-Density Rolled TA3 Titanium Bar / GR3 Titanium Rod for Aerospace Control System ComponentsNegotiableMOQ: 100 Kilograms

-

Wear-Resistant TC6 Titanium Alloy Bar / High-Performance Titanium Rod for Aerospace Mechanical PartsNegotiableMOQ: 100 Kilograms

-

High-Precision Machined TA7 Titanium Bar / Smooth-Surface Titanium Rod for Aerospace Instrument ComponentsNegotiableMOQ: 100 Kilograms

-

Forged TC4 Titanium Alloy Bar GR5 High-Density Forged Titanium Rod for Aerospace Structural PartsNegotiableMOQ: 100 Kilograms

-

Rolled TA2 Pure Titanium Bar GR2 Uniform-Thickness Rolled Titanium Rod for Industrial PipesNegotiableMOQ: 100 Kilograms

-

Precision Machined TC4ELI Titanium Bar GR5 ELI High-Precision Titanium Rod for Medical ImplantsNegotiableMOQ: 100 Kilograms

-

Forged TA9 Titanium Bar GR7 Wear-Resistant Forged Titanium Rod for Chemical Industry EquipmentNegotiableMOQ: 100 Kilograms

-

Rolled TC6 Titanium Alloy Bar Smooth-Surface Rolled Titanium Rod for Industrial Machinery ComponentsNegotiableMOQ: 100 Kilograms

-

Precision Ground TA1 Titanium Bar GR1 Ultra-Precision Titanium Rod for Medical Device PartsNegotiableMOQ: 100 Kilograms

-

Forged TC11 Titanium Alloy Bar Heavy-Duty Forged Titanium Rod for Aerospace Engine ComponentsNegotiableMOQ: 100 Kilograms