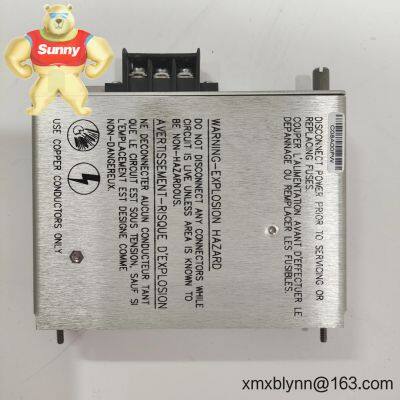

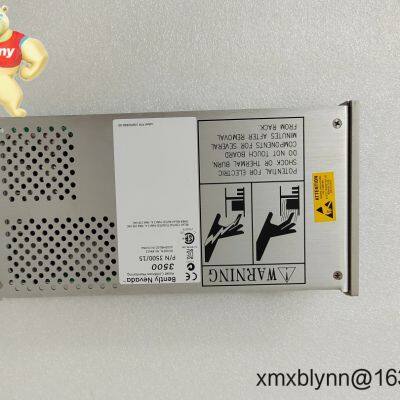

Bently Nevada 3500/15-05-05-CN Power Supply Module – Stable Rack Power for the 3500 Machinery Protection System

The 3500/15-05-05-CN is a dedicated power supply module for the Bently Nevada 3500 rack, designed to deliver clean, stable power to every monitor, relay, and communication card in the system. It supports redundant operation (primary + backup) to keep your protection and condition monitoring online even if one supply is removed or fails. From my experience, this module is chosen when plants want a no-drama, “fit-and-forget” supply with straightforward installation and predictable uptime.

Key FeaturesRack-wide regulated power – Feeds the entire 3500 backplane so all monitoring and relays receive stable power.

Redundancy support – Two supplies can be installed; one thing I appreciate is you can hot-swap a failed unit while the rack stays energized by the other.

Status indication – Front-panel LEDs provide quick health checks during commissioning or troubleshooting.

AC input variant – The -05-05-CN configuration is commonly associated with AC input versions used in general-purpose plant power systems.

Drop-in fit for 3500 racks – Installs in the designated power slot(s); no special tools or adapters in most cases.

Designed for 24/7 service – Built for continuous operation in industrial cabinets near turbines, compressors, and other rotating assets.

| Brand / Model | Bently Nevada 3500/15-05-05-CN |

| Power Requirements | AC input variant; typically suitable for standard plant AC mains (commonly 90–264 VAC, 47–63 Hz). Redundant operation supported with a second supply. |

| Output to Rack | Regulated backplane power for all installed 3500 modules; front LEDs indicate supply health. |

| Operating Temperature | Typically 0 to +60°C for 3500 platform deployments (verify against site conditions). |

| Signal I/O Types | N/A (power module; no process signal inputs/outputs) |

| Communication Interfaces | None (power only). Communications are handled by other 3500 modules. |

| Installation Method | Installs in the 3500 rack power supply slot(s); supports dual-supply redundancy and hot-swap when a second supply is present. |

| Compliance | CE and UL/CSA for the 3500 platform are typical; RoHS conformity is common on recent builds. |

The 3500/15 series is used anywhere a 3500 rack protects and monitors critical rotating equipment. You might notice it most in:

Gas and steam turbines in power generation (base-load and peaking plants)

Compressors and pumps in oil & gas, petrochemical, and refinery units

Large fans, blowers, and motors in steel, cement, paper, and mining operations

Critical utilities skids (boilers, chillers) where high availability monitoring is required

High availability – Redundant architecture reduces unplanned outages during maintenance or failure events.

Lifecycle continuity – Compatible with the 3500 ecosystem; spares strategy is straightforward for multi-site operators.

Lower total cost – Fewer nuisance trips and faster swaps translate into reduced downtime costs in many cases.

Clear status cues – LED indicators shorten troubleshooting time for electricians and control techs.

Proven in harsh environments – The 3500 platform has a long track record in continuous-duty services.

Quick field note: a maintenance lead at a petrochemical site mentioned they typically keep one spare 3500/15 on the shelf. When a power module started showing intermittent LED alarms, they swapped it in under 10 minutes with zero rack downtime thanks to the redundant supply.

Panel/cabinet – Mount the 3500 rack in a clean, ventilated cabinet. Maintain airflow around the rack; avoid heat sources.

Power wiring – Feed the supply from a stable AC source; using a UPS or conditioned mains is advisable for critical assets. Proper grounding is essential.

Redundancy – For high availability, install two 3500/15 supplies. You can replace one while the other maintains rack power.

Safety – De-energize the feed if you do not have a redundant unit online. Observe local electrical standards and lockout/tagout practices.

Routine care – Periodically check terminals for tightness, clean dust from vents, verify LED status, and record supply health during PM rounds.

Firmware/software – The power module itself doesn’t need firmware updates, but it’s good practice to keep the overall 3500 system configuration backed up.

Manufactured under ISO 9001 quality systems (platform level)

CE and UL/CSA compliance typically applicable to the 3500 platform

RoHS alignment on most current production units

Standard manufacturer warranty is typically 1 year; extended coverage may be available

Note: The “-05-05-CN” suffix appears to designate a specific AC input configuration and regional packaging/document set. If your site standard requires a DC-input power module, or if you need exact voltage/frequency details, I can match the supply code to your rack and share the verified datasheet before you order.

Send Inquiry to This Supplier

You May Also Like

-

Bently Nevada 330105-02-12-10-02-05 Proximity Probe – Non-contact Vibration and Shaft Displacement for Critical Rotating AssetsNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/40-01-01 Proximitor Monitor – 4‑Channel Radial Vibration Card for Critical Rotating MachineryNegotiableMOQ: 1 Combo

-

Bently Nevada 330130-045-02-05 Extension Cable – Reliable Interconnect for 3300 XL Proximity SystemsNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/44-XX-01 Vibration Monitor – 4‑Channel Machine Protection for Critical Rotating AssetsNegotiableMOQ: 1 Combo

-

Bently Nevada 330106-05-30-05-02-05 Vibration/Displacement Probe for Critical Rotating MachineryNegotiableMOQ: 1 Combo

-

Bently Nevada 330130-045-01-05 Extension Cable – Reliable Link for 3300 XL Proximity Probe SystemsNegotiableMOQ: 1 Combo

-

Bently Nevada 990-08-XX-01-CN Vibration Transmitter (P/N 283278-01) – 4–20 mA Machine Condition Signal for DCS/PLCNegotiableMOQ: 1 Combo

-

Bently Nevada 330130-080-13-CN – 3300 XL Extension Cable for Proximity Transducer SystemsNegotiableMOQ: 1 Combo

-

Bently Nevada RRE004382 Vibration Probe for Centrifugal Compressors – Non‑contact Shaft Vibration SensingNegotiableMOQ: 1 Combo

-

Bently Nevada 330101-37-57-10-02-05 – Proximity Probe for Vibration and Shaft Displacement MonitoringNegotiableMOQ: 1 Combo