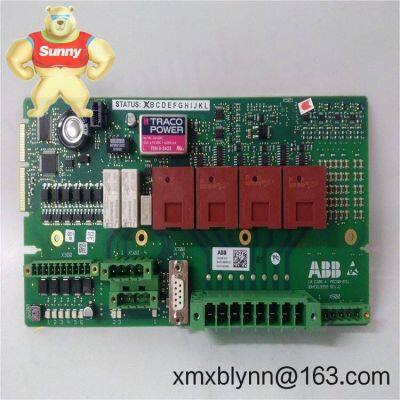

ABB UAD206A101 (3BHE019958R0101) – Mixed I/O Interface Board for ABB Industrial Control and Excitation Systems

Warranty: 365 days

Lead time: 1 week if in stock; no more than one month at the latest

Payment: 50% advance payment; full payment before delivery

Express options: FedEx, UPS, DHL

Mixed-signal I/O front-end: Handles both analog measurement and digital status/control signals for ABB control systems.

Backplane communication: Connects to the host controller via ABB’s backplane bus; no field wiring directly to Ethernet ports, which keeps noise down in many cases.

Industrial-grade design: Built for 24/7 environments; conformal coating variants are typically available for harsh conditions.

Service-friendly layout: Plug-in replacement with guided connectors—maintenance teams usually swap it in minutes when the cabinet is prepared.

Signal conditioning onboard: Isolation and filtering stages (as applicable) help stabilize readings in noisy motor rooms.

Diagnostics indicators: Status LEDs (where present) speed up commissioning and fault tracing.

Compatibility-first approach: Commonly applied with ABB AC 800PEC and UNITROL platforms to maintain system-level compatibility and lifecycle continuity.

| Brand / Model | ABB UAD206A101 (3BHE019958R0101) |

| HS Code | 8538.90 – Parts for switching/protection/controls of heading 8535–8537 (industrial control parts) |

| Power Requirements | Supplied via host system backplane (typically derived from 24 VDC cabinet supply) |

| Signal I/O Types | Mixed analog and digital channels; exact channel count depends on board revision and application setup |

| Communication Interfaces | Proprietary backplane interface to ABB controller; no direct fieldbus on the front edge for this board |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated cabinet per ABB guidelines |

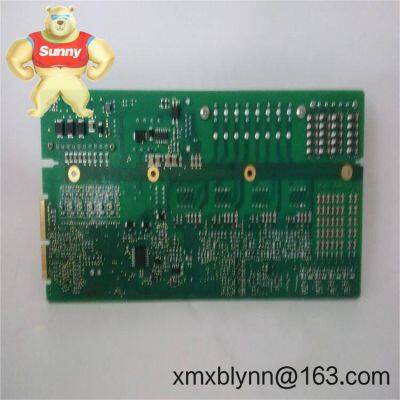

| Installation Method | Plug-in PCB module; mounts in ABB card frame/backplane with retention screws |

| Dimensions & Weight | Compact form-factor board; consult the system drawing for exact footprint and mass |

This board shows up in power electronics controls where fast, deterministic I/O is needed. Typical environments include:

AC/DC drive cabinets (steel and paper lines, mining conveyors, marine propulsion)

UNITROL-based generator excitation and power plant auxiliaries

Wind and test-bench converters using AC 800PEC control

High-performance motion or rolling mill stands where robust noise immunity is essential

A maintenance lead from a paper mill told me they swapped a UAD206A101 in under 20 minutes during a night shift—no software changes, just careful ESD handling—and the drive line was back at speed before the next reel change. That’s typically the kind of low-drama service event plants want.

Reliability: ABB boards like this are built for continuous operation and stable signal integrity.

Compatibility: Designed to work within ABB control ecosystems (AC 800PEC / UNITROL), reducing integration risk.

Lifecycle support: Keeps legacy and current cabinets serviceable—cost savings versus wholesale redesign.

Maintenance speed: Plug-in architecture shortens MTTR, which in many cases saves far more in downtime costs than the part itself.

Quality traceability: Clear part coding (3BHE019958R0101) supports documentation and spare part management.

Cabinet conditions: Install in a clean, ventilated enclosure; maintain airflow paths and avoid heat sources directly beneath the board.

Grounding & shielding: Bond cabinet PE properly; route shielded signal cables with single-point grounding to minimize noise.

Backplane integrity: Inspect card guides and connectors; reseat with even pressure and secure retention screws.

ESD handling: Use wrist straps and antistatic packaging; avoid touching component pins or analog front-end areas.

Routine checks: Quarterly visual inspection for dust, discoloration, or loose connectors; clean with dry air per site policy.

Firmware/config: If the application uses controller-resident firmware parameters, back up settings before replacement; restore and verify I/O scaling after swap.

CE marking: Conforms as part of the complete ABB system

ISO 9001 manufacturing: Produced under ABB’s quality management system

RoHS: Typically compliant for standard variants

Warranty: 365 days (exchange/repair per inspection)

ABB AC 800PEC controller and carrier backplane (host CPU and rack)

UNITROL excitation platform components (for generator applications)

Shielded cable sets and terminal adapters for analog/digital field wiring

Filtered 24 VDC power supply modules and EMC cabinet accessories

Note: Channel counts and exact I/O mapping can vary by system configuration and board revision. If you share your cabinet type and controller setup, I can match the UAD206A101 to the correct backplane slot and provide a wiring/commissioning checklist.

Send Inquiry to This Supplier

You May Also Like

-

ABB UNS4684a-P;V.1 PCB – Reliable Plug-in Control Board for ABB Rack-based DCS/automation SystemsUS$ 5140.00MOQ: 1 Pallet

-

ABB XVC767AE105 (3BHB007209R0105) – Control Board for ACS800/Multidrive SystemsUS$ 10416.00MOQ: 1 Pallet

-

ABB PM860AK01 3BSE066495R1 – AC 800M CPU Kit for Reliable, Scalable Process ControlUS$ 4816.00MOQ: 1 Pallet

-

ABB PM860AK01 3BSE066495R1 – AC 800M CPU Kit for Reliable, Scalable Process ControlUS$ 4816.00MOQ: 1 Pallet

-

ABB S-113H 3BHB018008R0003 – Gate Driver Board for ABB Industrial Drive Inverter StacksUS$ 170460.00MOQ: 1 Pallet

-

ABB PU515A RTA Board (3BSE032401R1) – Controller-internal Interface Board for ABB DCS Maintenance and UpgradesUS$ 5880.00MOQ: 1 Piece

-

ABB UAD215A101 (3BHE026284R0101) – Control/IO Board for ABB Industrial Drive and Excitation SystemsUS$ 3065.00MOQ: 1 Unit

-

ABB SDCS-CON-2-COAAT Control Board – Core Controller for ABB DCS500/DCS600 DC Drive SystemsUS$ 1648.00MOQ: 1 Piece

-

ABB PP886H (3BSE069297R1) – Panel 800 HMI for Reliable Machine and Process VisualizationUS$ 2465.00MOQ: 1 Pallet

-

ABB REC670 (1MRK002814-AC) – High‑performance Bay Control IED for Substation AutomationUS$ 4705.00MOQ: 1 Unit