Incoloy 825 Nickel Alloy Discs for Tubesheets

1. Product Overview

Our Incoloy 825 nickel alloy discs for tubesheets are a high - performance solution designed to meet the demanding requirements of various industrial applications. These discs are crafted from Incoloy 825, a nickel - iron - chromium alloy with excellent corrosion resistance and mechanical properties.

2. Alloy Composition and Advantages

- Composition: Incoloy 825 is composed of approximately 42% nickel, 22% chromium, 3% molybdenum, 2.2% copper, and small amounts of titanium and iron. This unique composition gives it outstanding resistance to a wide range of corrosive environments.

- Corrosion Resistance: It has excellent resistance to both reducing and oxidizing acids. For example, it can withstand sulfuric acid, phosphoric acid, and nitric acid environments, making it suitable for use in chemical processing plants. In addition, it shows remarkable resistance to stress - corrosion cracking in chloride - containing solutions, which is a common problem in many industrial settings.

- Mechanical Properties: The alloy has high strength and good ductility. It can withstand high - temperature and high - pressure conditions without significant deformation. This makes it ideal for use in tubesheets where it needs to maintain its integrity under challenging operating conditions.

3. Surface Treatment

- Our discs undergo a meticulous polishing surface treatment. This not only gives them an aesthetically pleasing silver color but also has practical benefits. The polished surface reduces the roughness of the disc, which in turn minimizes the adhesion of contaminants and corrosive substances. It also makes the discs easier to clean, which is crucial in applications where hygiene and purity are important, such as in the food and beverage industry or pharmaceutical manufacturing.

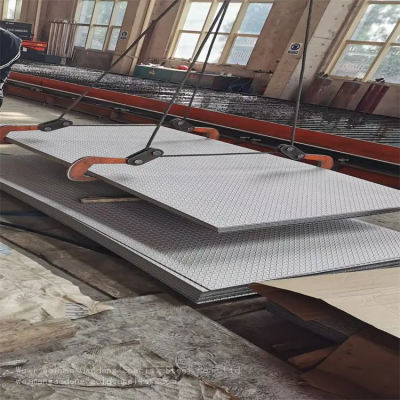

4. Customization

- One of the key features of our Incoloy 825 nickel alloy discs is the ability to customize them according to your specific blueprint. Whether you need a particular diameter, thickness, or hole pattern for your tubesheet, our manufacturing process can accommodate your requirements. Our experienced engineering team will work closely with you to ensure that the final product meets your exact specifications. This customization option provides flexibility and allows you to optimize the performance of your tubesheets in your unique application.

5. Quality Assurance

- As a professional manufacturer established in 2017, we have a strict quality control system in place. Our company, with a team of 11 - 20 experienced sales representatives, is committed to delivering products of the highest quality. We source our raw materials from reliable suppliers and conduct multiple quality inspections during the manufacturing process. Each disc is inspected for dimensional accuracy, surface finish, and material properties to ensure that it meets or exceeds industry standards.

6. Application Areas

- Chemical Industry: Incoloy 825 discs for tubesheets are widely used in chemical reactors, heat exchangers, and piping systems. Their corrosion resistance helps to prevent leakage and equipment failure, ensuring the safe and efficient operation of chemical plants.

- Oil and Gas Industry: In offshore platforms and refineries, these discs are used in tubesheets for condensers, coolers, and other heat - transfer equipment. The harsh marine and chemical environments in the oil and gas sector require materials with high corrosion resistance, and Incoloy 825 fits the bill perfectly.

- Power Generation: In power plants, whether they are fossil - fuel - based or nuclear, tubesheets play a crucial role in heat - transfer processes. Our Incoloy 825 discs can withstand the high - temperature and high - pressure conditions in these applications, ensuring reliable power generation.

7. Global Reach

- With an annual export volume ranging from US$5 million to US$10 million, our products have reached many parts of the world. Our main markets include North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, the Middle East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, and South Asia. We understand the different requirements and standards in these regions and can provide products that meet local regulations and customer expectations.

In conclusion, our Incoloy 825 nickel alloy discs for tubesheets are a reliable, high - quality, and customizable solution for a wide range of industrial applications. Their excellent corrosion resistance, mechanical properties, and surface finish make them a top choice for tubesheet applications in various industries.

Send Inquiry to This Supplier

You May Also Like

-

High Quality Polished Brushed Nickel Based Alloys Incoloy 945 Sheet/PlateNegotiableMOQ: 1 Ton

-

New Arrivals Super Alloys for High Temperature Structural Applications Haynes 282 Coil/StripNegotiableMOQ: 1 Ton

-

High-Performance Haynes 230 Nickel Alloy Steel Plate for SaleNegotiableMOQ: 1 Ton

-

Haynes75/Uns N06075/Haynes 233 Steel Plate/Sheet Manufacture CustomizableNegotiableMOQ: 1 Ton

-

Haynes 75 Alloy Nickel Alloy Steel Sheet Plate Oxidation and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

High Temperature Alloy Uns R30188/Kcn22W/Haynes188 Nickel Plate/Sheet Direct SupplyNegotiableMOQ: 1 Ton

-

Customized Hastelloy Haynes188 R30188 Nickel Alloy PlateNegotiableMOQ: 1 Ton

-

Haynes230/ 230-W/N06230 Nickel Alloy Steel Coil Foil Strip for Industrial UsesNegotiableMOQ: 1 Ton

-

Haynes 214 Nickel Alloy Strip/Coil/Foil Complete Specifications Good PriceNegotiableMOQ: 1 Ton

-

Haynes 242 N10242 Corrosion-Resistant Alloy Pipe/ Tube Long-Term DurabilityNegotiableMOQ: 1 Ton