Home > Products > Titanium Alloy > High-Strength Premium Grade Titanium Alloy Rods - Tc4, Gr5, Ti6al4V

High-Strength Premium Grade Titanium Alloy Rods - Tc4, Gr5, Ti6al4V

- SHANGHAI

- T/T L/C PayPal D/P Western Union

- 7 days

You May Like

-

High Quality Customized Titanium Alloy Bar Grade5 Tc4 Gr5 Bt6 Titanium Bar Rod Price Per Kg

-

High Strength Grade2 Ta2 Tp340 Titanium Rods ASTM B265 Corrosion Resistant Gr5 Ti6al4V Tc4 Titanium Rod

-

Customized Gr5 Tc4 Gr9 Ta5 Ta17 50.8*305mm Lathe Finishtitanium Rod Bar Used for Corrosion Resistant Industrial Titanium

-

Gr12 Polished Titanium Rods High-Purity Pure Ti Ta2 Titanium Alloy Bar Medical Titanium Rod

-

High Quality Titanium Material Ta2 Titanium Bar ASTM B348 Tc4 Titanium Alloy Rod

-

China Supply Gr2 Gr6 Gr7 Titanium Bar Ti6al4V Alloy Titanium Rod Ta6V Eli Gr5 Per Kg Price

Product Details

| Shape | Round | Grade | Other, TA1、TA2、TA8、TA9、TA10、TC4(Ti-6Al-4V)、 TC11、TA15、Gr1、Gr2、Gr16、Gr7、Gr12、Gr5 | |

| Technique | Forged | Application | Industrial | |

| Type | Titanium Bars |

Product Description

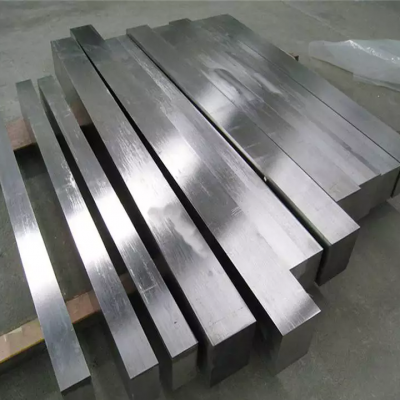

High-Strength Premium Grade Titanium Alloy Rods - Tc4, Gr5, Ti6al4V

1. Product Overview

Our high - strength premium grade titanium alloy rods, specifically in the Tc4 (Ti - 6Al - 4V) and Gr5 specifications, are a remarkable addition to the industrial materials market. Titanium alloy is well - known for its outstanding combination of properties, and these rods are no exception. They are forged to achieve superior quality and performance, making them suitable for a wide range of industrial applications.

2. Material Properties

- High Strength: The Tc4/Gr5 titanium alloy rods possess excellent tensile strength. This high strength - to - weight ratio makes them ideal for applications where strength is crucial, yet weight needs to be minimized. For example, in aerospace components, every gram counts, and these rods can provide the necessary structural integrity without adding excessive mass.

- Corrosion Resistance: Titanium alloys are highly resistant to corrosion, even in harsh environments. These rods can withstand exposure to various chemicals, seawater, and high - humidity conditions. This property is particularly valuable in marine and chemical processing industries, where corrosion can lead to equipment failure and costly repairs.

- Heat Resistance: With good heat resistance, these rods can maintain their mechanical properties at elevated temperatures. They can operate in high - temperature industrial processes without significant degradation, ensuring long - term reliability in applications such as engine components and high - temperature furnaces.

3. Manufacturing Technique

These titanium alloy rods are produced using the forging technique. Forging offers several advantages over other manufacturing methods.

- Improved Grain Structure: During forging, the metal's grain structure is refined and aligned, which enhances the overall strength and toughness of the rods. This results in a more uniform and reliable product with fewer internal defects.

- Enhanced Mechanical Properties: The forging process can optimize the mechanical properties of the titanium alloy, such as ductility and fatigue resistance. This makes the rods more durable and better able to withstand repeated stress and strain in industrial applications.

4. Product Specifications

- Shape: The rods have a round shape, which is a common and versatile form. The round shape allows for easy machining, fitting, and integration into various industrial systems. It can be used for shafts, bolts, and other components where a circular cross - section is required.

- Grades: Available in multiple grades including TA1, TA2, TA8, TA9, TA10, TC4 (Ti - 6Al - 4V), TC11, TA15, Gr1, Gr2, Gr16, Gr7, Gr12, Gr5. Each grade has its own unique set of properties, allowing customers to choose the most suitable grade based on their specific application requirements. For instance, Gr5 (Tc4) is known for its high strength and is widely used in aerospace and high - performance engineering applications.

5. Applications

- Aerospace Industry: In the aerospace sector, these titanium alloy rods are used in the manufacturing of aircraft structural components, engine parts, and landing gear. Their high strength, low weight, and excellent heat resistance make them essential for ensuring the safety and performance of aircraft.

- Marine Industry: Due to their corrosion resistance, the rods are suitable for marine applications such as shipbuilding, offshore platforms, and underwater equipment. They can withstand the corrosive effects of seawater and provide long - lasting service in harsh marine environments.

- Medical Industry: Titanium alloy is biocompatible, which makes these rods suitable for medical applications. They can be used in the production of orthopedic implants, dental implants, and surgical instruments, providing a safe and reliable solution for patients.

- Chemical Processing Industry: In chemical plants, these rods can be used in equipment that comes into contact with corrosive chemicals. Their corrosion resistance ensures the integrity of the equipment and helps prevent chemical leaks and environmental hazards.

6. Company Background

Our company, founded in 2017, is a professional manufacturer of stainless steel, alloy steel pipe, nickel - based alloy, and titanium alloy. With an export share ranging from US$5 Million - US$10 Million, we have a strong presence in the international market. Our team consists of 11 - 20 experienced salespersons, who are dedicated to providing high - quality products and excellent customer service. Our products are exported to a wide range of markets, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as our domestic market.

If you are interested in our high - strength premium grade titanium alloy rods, please feel free to contact our manager, Sang Le. You can reach us via WhatsApp at +8615995395119 or by mobile phone at 86 - 13373665027. Our company is located at No. 168 Qiangao Road, ready to serve your industrial material needs.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1. Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2. Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3. Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4. Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Good Quality with Reasonable Prices ASTM Grade2 Gr2 ASTM Titanium Bar and Rod with Competitive Price and Excllent Performance

-

Titanium Rod Price Gr7 Gr12 Gr5 Corrosion-Resistant High-Temperature Resistant Titanium Alloy Rod for Petrochemical Industry

-

Factory Supplies Titanium Rod Stock Ta3 Gr3 Ta4 Gr4 High-Quality Titanium Alloy Rod for Manufacturing Aircraft Parts

-

2025 Factory Price Gr1、Gr2、Gr16 Titanium Round Rod Titanium Tungsten Alloy Rod

-

ASTM A213 Tp347hfg Seamless Stainless Steel Pipe

-

High-Quality Datang AISI Tp347hfg Stainless Steel Seamless Tube

-

ASTM A213 Tp347hfg Honed Oval Polished Seamless Stainless Steel Pipe

-

ASTM A213 ASME SA213 Tp347hfg Seamless Steel Tubes

-

ASME SA213 T91 T122 10crmo9 Tp310 Tp347hfg alloy Steel boiler tube

-

ASTM A312 Tp316L Cold Rolled Rectangular Polished Seamless Stainless Steel Pipe

-

ASTM A213 TP304L Honing Triangle Polished Seamless Stainless Steel Tube

-

10cr18ni9nbcu3bn Stainless Steel Tube High-Temperature Nickel Based Alloy

-

Factory 27simn 07cr2mow2vnbb 09crmoal 09mnd 10cr18ni9nbcu3bn Seamless Alloy Steel Pipe Tube

-

Hot Rolled ASME 10cr18ni9nbcu3bn Stainless Steel Tube Seamless Alloy Tubing ASTM for Boilers

-

63*5.5 Thickness 10cr18ni9nbcu3bn 07cr25ni21nbn SUS304htb Inox Pipe Boiler Tube

-

China Factory Directly ASTM A213 Tp 316 Seamless Stainless Steel Pipe

-

Wholesale Inox Manufacturer 309S,310S 20cr13 Polished Price Per Ton Stainless Steel Pipe

-

Premium 2Cr13 Stainless Steel Sheet with No. 4 Finish stainless steel round bar

-

Professional Supply of High Quality 2Cr13 Round Steel, Stainless Steel Bar 420, 2Cr13 Round Steel

-

Chinese Factory ASTM 430 410 420 2Cr13 3Cr13 4Cr13 Stainless Steel Pipe

-

63*5.5 inventory specification TP347HFG stainless steel pipe

-

57*12.5 Weiman Gordon Special Steel TP310HCbN seamless steel pipe

-

63*5.5 inventory specification TP347H stainless steel round pipe

-

Ferritic 430 stainless steel pipe, 2Cr13, 3Cr13 precision rolled seamless pipe

Popular Searches

- square bar

- round rod bar

- hexagonal bar

- titanium alloy

- titanium material

- forged bar

- copper bar

- titanium plate

- titanium tube

- golf cart

- titanium sheet

- titanium foil

- titanium ring

- titanium wire

- titanium rod

- titanium round bar

- titanium metal

- titanium bike frame

- titanium pipe

- titanium alloy bar

- titanium alloy round bar

- titanium medical bar

- titanium rod bar

- titanium flat bar

- flat wire bar

- stainless steel

- bicycle frame

- titanium material

- titanium plate

- titanium bar

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Non-ferrous Metal & Products > Titanium

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile