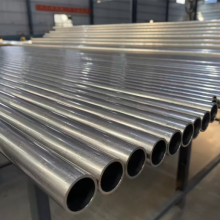

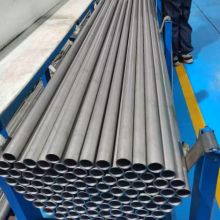

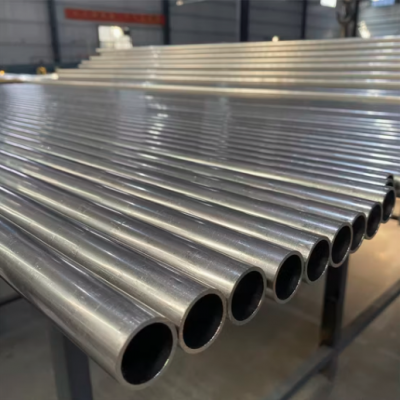

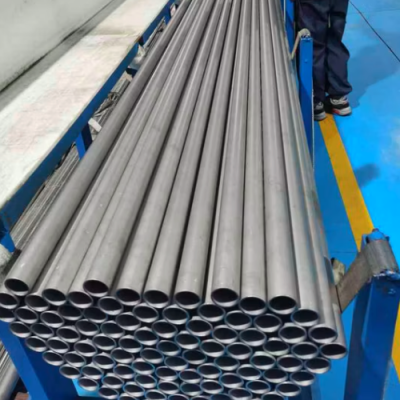

ASTM B163 Nickel Alloy 825 Tubing Uns N08825 12mmx1.5mm Bright Annealed Cold Drawn Seamless Steel Pipe for Oil and Gas Power Generation

NAI LOK CO., Ltd established in 2000. has made a name of itself in the list of top suppliers of in China. We focus on the production, research and development, sales of high quality nickel alloy tube and high purity seamless tube. We have more than 20 years of precision tube manufacturing and 10 years of export experience.

Our annual design capacity is 1, 500 tons of seamless steel tubes, utilizing a cold rolling-based process that leads domestically, combined with rolling and drawing processes. We can also provide ODM, OEM and agency services for global customers.

Nickel Alloy Seamless Tube are widely used in petrochemicals, semiconductor manufacturing, instrumentation, military, nuclear power, and other industries, as well as in cutting-edge scientific fields such as national defense and aerospace.

400Series:UNS N04400

600Series:UNS N06600,UNS N06601,UNS N06625

800Series:UNS N08800,UNS N08810,UNS N08811,UNS N08825

Pure Nickel Alloy Tube:UNS N02200,UNS N02201

UNS N10276,UNS N06022,UNS N06200,UNS N10665,UNS N10675

High Temperature Alloy:GH3030,GH3039

Other type Alloy:UNS N08020,UNS N08028

| Material | Stainless steel SS316 UNS S31603 |

| Wall Thickness | 0.028inch - 0.083 inch |

| Length | 6000mm(optional:4000mm),(+/-10% possible) |

| Inside Surface Roughness | BA grade:Ra≤0.6μm EP grade:Ra≤0.25μm |

| Size | 1/8"- 6" |

Ordering Informatin

| Part Number | Tube OD(in) | Wall Thickness(in) | Length(mm) |

| TSSM-02T028L06 | 1/8 | 0.028 | 6000 |

| TSSM-04T035L06 | 1/4 | 0.035 | 6000 |

| TSSM-04T049L06 | 1/4 | 0.049 | 6000 |

| TSSM-04T065L06 | 1/4 | 0.065 | 6000 |

| TSSM-06T035L06 | 3/8 | 0.035 | 6000 |

| TSSM-06T049L06 | 3/8 | 0.049 | 6000 |

| TSSM-06T065L06 | 3/8 | 0.065 | 6000 |

| TSSM-08T035L06 | 1/2 | 0.035 | 6000 |

| TSSM-08T049L06 | 1/2 | 0.049 | 6000 |

| TSSM-08T065L06 | 1/2 | 0.065 | 6000 |

| TSSM-10T065L06 | 5/8 | 0.065 | 6000 |

| TSSM-12T065L06 | 3/4 | 0.065 | 6000 |

| TSSM-16T083L06 | 1 | 0.083 | 6000 |

| TSSM-20T095L06 | 1-1/4 | 0.095 | 6000 |

| TSSM-20T120L06 | 1-1/4 | 0.120 | 6000 |

| TSSM-24T120L06 | 1-1/2 | 0.120 | 6000 |

| TSSM-24T134L06 | 1-1/2 | 0.134 | 6000 |

| TSSM-32T134L06 | 2 | 0.134 | 6000 |

| TSSM-32T188L06 | 2 | 0.177 | 6000 |

Hastelloy C276 tubes are highly versatile and find extensive applications across various industries due to their exceptional corrosion resistance, high temperature stability, and mechanical properties. Here are some common applications of Hastelloy C276 tubes:

Chemical Processing: Hastelloy C276 tubes are widely used in the chemical processing industry for transporting and processing corrosive chemicals, acids, and solvents. They are employed in applications such as chemical reactors, distillation columns, heat exchangers, and piping systems where resistance to pitting, crevice corrosion, and stress corrosion cracking is crucial.

Oil and Gas: In the oil and gas industry, Hastelloy C276 tubes are utilized in downhole applications, such as tubing and casing, where they provide excellent resistance to corrosion from acidic fluids, hydrogen sulfide (H2S), and chloride ions. They are also used in surface equipment such as heat exchangers, separators, and pipelines in offshore and onshore facilities.

Power Generation: Hastelloy C276 tubes are employed in power generation plants, including fossil fuel, nuclear, and renewable energy facilities, for applications such as boiler tubes, heat exchangers, condensers, and piping systems. They offer superior corrosion resistance in environments containing high temperatures, steam, and aggressive chemicals.

Pulp and Paper: In the pulp and paper industry, Hastelloy C276 tubes are utilized in digester systems, bleach plants, evaporators, and chemical recovery processes where they withstand the corrosive effects of chlorine, chlorine dioxide, and other chemicals used in pulp bleaching and processing.

Desalination: Hastelloy C276 tubes are used in desalination plants for seawater and brackish water desalination processes. They resist corrosion from seawater and saline solutions, making them suitable for evaporators, condensers, and piping systems in reverse osmosis and thermal desalination systems.

Aerospace: Hastelloy C276 tubes find applications in aerospace engineering for components exposed to corrosive environments, such as aircraft exhaust systems, engine components, and hydraulic systems where resistance to corrosion and high temperatures is critical for safety and performance.

Pharmaceuticals: Pharmaceutical manufacturing facilities utilize Hastelloy C276 tubes for processing equipment involved in the production of pharmaceutical products. They are used in reactors, vessels, and piping systems handling corrosive chemicals and sterilization processes.

Waste Treatment: Hastelloy C276 tubes are employed in waste treatment facilities for handling corrosive chemicals and harsh environments in scrubbers, absorbers, and reaction vessels used for neutralization, oxidation, and other treatment processes.

Overall, Hastelloy C276 tubes are preferred in industries where corrosion resistance, reliability, and longevity are essential, making them suitable for a wide range of demanding applications in aggressive environments.

Zhongzheng Stainless Steel Co., Ltd. was established in 2018 with aregistered capital of 20 million yuan. lt is a manufacturing company thatintegrates the production of special materials, manufacturing andprocessing, sales, and technology development. The company covers anarea of 2,000 square meters and has 200 employees. it has built worldclass stainless steel seamless pipe (hot piercing, cold drawing, cold rollingproduction lines, precision steel pipe production lines, and large, mediumand small-sized welded pipe production lines. The company has beencommitted to providing high performance, high precision, hightemperature-resistant, high pressure-resistant, and corrosion-resistantsolutions and technical services for industrial equipment pipeline systems.The company specializes in producing a series of steel pipes, pipe fittingsflanges, etc., such as high-temperature (nickel-based) alloys, austeniticduplex steel, urea grade stainless steel, super stainless steel, etc. Thecompany is equipped with an annual production capacity of 5,000 tons ofstainless steel seamless pipe production line, 7,000 tons of welded pipeproduction line, and 500 tons of pipe fittings production line, etc. lt canoroduce stainless steel seamless pipes with diameters ranging from Φ6 toΦ762 and wall thicknesses ranging from 0.5 to 70 mm, stainless steelwelded pipes with diameters ranging from Φ15 to Φ2200 and wallthicknesses ranging from 0.5 to 80 mm, pipe fittings, and various stainlesssteel ingots, round steel, rough pipes, etc., according to customerrequirements and in accordance with standards such as GB, ASTM, etc.

Call to Action (CTA)

📞 Contact Now for Best Price!

📧 Email: jane@zjzzgy.cn

💬 WhatsApp: +86 19005872308

Send Inquiry to This Supplier

You May Also Like

-

Alloy C-276/Hastelloy C-276 Nickel Alloy Steel Seamless Pipe From China for Chemical ProcessingUS$ 800 - 1100MOQ: 1 Ton

-

Good Quality Tube Nickel Based Stainless Steel Hastelloy C-276 Pipe SeamlessUS$ 800 - 1100MOQ: 1 Ton

-

SUS201 304 316 Austenitic Welded Tube Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

Large Diameter 304 Stainless Steel Seamless Pipe Round Tube 304/L/H/Ln 316L/H/Ln/Ti Super Austenitic Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

Alloy 310 & 310S Austenitic Stainless Steel Seamless Tubes in Standards Astma312/A269 for Oil and Gas Industry Pipeline UsingUS$ 800 - 1100MOQ: 1 Ton

-

Ss AISI China Factory Cheap Industrial SS304 316L Grade Stainless Steel Pipe PriceUS$ 1500MOQ: 1 Ton

-

Welding Industrial Material 1.5 Inch 304 316L Stainless Steel Food Grade Tube and PipeUS$ 1600MOQ: 1 Ton

-

Stainless Steel Heat Resistance Industrial Grade Seamless Pipes for Pharmaceutical IndustryUS$ 2000MOQ: 1 Ton

-

304/L/H/Ln 316L/H/Ln/Ti Super Austenitic Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

304/L 316 316L Austenitic Ss Seamless Tube Bright Annealing Stainless Steel TubeUS$ 800 - 1100MOQ: 1 Ton