Type

Hard Plastic Crusher

Certification

CE, ISO9001:2008

Warranty

12months

Structure

Top Feed

Raw Material

PET

After-sales Service

technical service all lifespan

Automation

Automatic

Computerized

Non-Computerized

Knife Classification

Piece Knife Crusher

Knife Roll

Solid Knife Roller

Transport Package

plywood case or customized

Specification

customized

Trademark

utmach

Origin

zibo, china

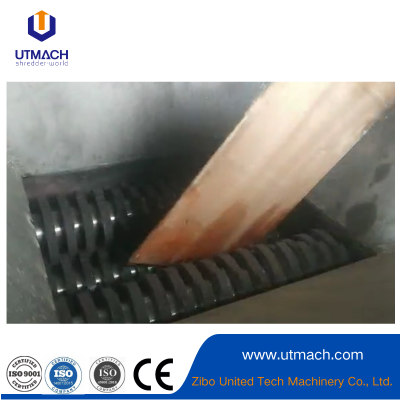

Four-Shaft Shredder: Unleashing Power and Efficiency

The four-shaft shredder stands as a paragon of innovation in material processing machinery. With its distinctive quad-shaft design, it pairs two sets of counter-rotating shafts, each outfitted with interlocking, wear-resistant blades. This setup creates a formidable shearing force, enabling it to effortlessly shred resilient materials like industrial-grade plastics, thick metal sheets, and even discarded tires.

Operating at a slow speed yet delivering high torque, the shredder minimizes noise pollution and energy consumption, making it a sustainable choice for modern industries. Its intelligent control system monitors real-time parameters such as motor load and blade speed, automatically adjusting operations to prevent jams and optimize performance. The modular construction of the blades and shafts simplifies maintenance—worn components can be swiftly replaced, reducing downtime significantly.

Widely adopted across waste recycling plants, manufacturing facilities, and e-waste disposal centers, the four-shaft shredder excels in pre-processing materials. It not only reduces waste volume for efficient storage and transportation but also recovers valuable resources from recyclables, contributing to a circular economy. Its combination of raw power, operational finesse, and eco-friendliness solidifies its position as an indispensable workhorse in contemporary industrial applications.