Home > Products > Steel Ball Hot Rolling-Forging Furnace > Grinding steel ball hot rolling induction system

Grinding steel ball hot rolling induction system

- 1000 Set / Sets per Month

- tianjin

- T/T L/C

- 40 days

You May Like

-

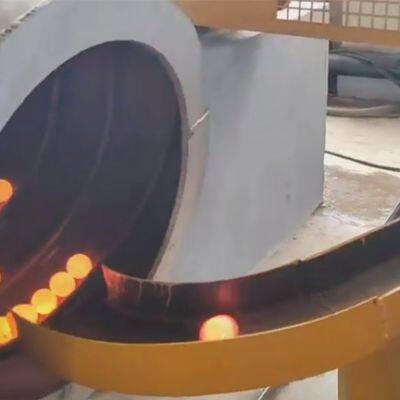

Grinding steel ball hot rolling induction process furnace

-

Medium frequency induction heating power supply for furnace

-

Medium frequency heating power supply for induction furnace

-

Induction heating power supply for induction furnace

-

Intelligent induction heating power supply for furnace

-

Energy-saving induction heating power

Product Details

| Brand Name | Forever | Place of Origin | China | |

| After-sales Service Provided | Engineers available to service machinery overseas | Condition | New |

Product Description

Main technical parameters of hot rolled steel ball heating line :

Workpiece material: B2 B3、B6、70Cr2、75Mncr、65Mn、60Mn、GCr15、40Cr、45#。

Power supply system: KGPS200-6000KW or IGBT200-2000KW, with an hourly output of 0.2-16 tons.

Sensor design: variable pitch, temperature gradient design, for higher efficiency.

Elastic adjustable pressure roller: enables workpieces of different diameters to feed at a uniform speed, and the roller tracks and pressure rollers between the furnace bodies are made of 304 non-magnetic stainless steel and water-cooled.

Infrared temperature measurement: An infrared temperature measurement device is installed at the discharge end to ensure that the temperature of the bar before entering the rolling mill is consistent.

▲ Energy conversion: Heating to 930 ℃~1050 ℃ consumes 260-280 degrees of electricity.

Working principle of steel ball forging production line :

The working principle of spiral pass oblique rolling is shown in the figure. Two rolling rolls with spiral passes cross each other's axes, and the rolling rolls rotate in the same direction to drive the circular rolling piece to rotate and move forward. Under the action of the spiral pass, the rolling piece forms a blank of the rotating body part. The deformation of oblique rolling is mainly due to axial extension of diameter compression.

Advantages and characteristics of steel ball hot rolling production line :

1. The production efficiency of steel balls is high. Due to the fast speed of the intermediate frequency heating furnace, it meets the rolling requirements of the rolling mill, greatly improving the production efficiency of steel balls.

2. The degree of automation is high, and the entire set of steel ball hot rolling equipment is fully automated from feeding to rolling and then to heat treatment, greatly reducing labor intensity, reducing human interference factors, and improving the quality of steel ball production.

3. Due to the fast heating speed of the intermediate frequency and the short contact time between the surface of the round steel and the air, the surface oxidation of the round steel is greatly reduced, the amount of oxide skin generated is reduced, the utilization rate of the round steel is improved, production costs are saved, and the production efficiency of steel balls is improved.

4. The hot-rolled steel ball equipment adopts clean energy, which does not produce environmental pollution factors such as exhaust gas, wastewater, and noise during the production of steel balls. The cooling water is recycled and not discharged, which meets environmental protection requirements.

5. The wear-resistant steel balls produced by hot-rolled steel ball equipment have high overall hardness, high impact toughness, and low crushing rate, and are highly praised by users in various industries such as black and non-ferrous metal mines, thermal power plants, cement plants, refractory material plants, etc.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Contact Us

- Hebei YuanTuo Electromechanical Equipment Mnufacturing Co.Ltd.

- Contact nameTom Chat Now

Product Categories

New Products

-

Energy-saving induction heating power for induction furnace

-

IGBT intelligent induction heating power supply

-

IGBT intelligent induction heating power supply for induction heater

-

Energy-efficient electric heating power supply

-

Energy-efficient electric heating power supply for furnace

-

Deformed bar hardening and tempering furnace

-

Deformed bar hardening and tempering machine

-

Deformed bar hardening and tempering equipment

-

New steel pipe annealing induction heating machine

-

Medium frequency steel tube annealing induction machine

-

Medium frequency steel tube annealing induction equipment

-

Medium frequency steel tube annealing induction furnace

-

Medium frequency steel tube annealing induction system

-

Energy-saving steel pipe annealing induction furnace

-

Energy-saving steel pipe annealing induction machine

-

Energy-saving steel pipe annealing induction equipment

-

Energy-saving steel pipe annealing induction line

-

Energy-saving steel pipe annealing induction system

-

Energy-saving steel pipe annealing induction process

-

High-Level steel pipe annealing induction furnace

-

High-Level steel pipe annealing induction machine

-

High-Level steel pipe annealing induction equipment

-

High-Level steel pipe annealing induction production line

-

High-Level steel pipe annealing induction device-steel pipe heater

Popular Searches

- feeder machine

- automatic feeder

- fish feeder

- fashion buckle

- metal buckle

- Metal Belt Buckle

- Zinc Alloy Belt Buckle

- Plastic Buckle

- Metal Pin Buckle

- remote control robot

- robot arm

- palletizing

- Side Release Buckle

- commutator

- luggage strap belt

- purse hook

- Toilet Partition

- metal d ring

- D Ring Buckle

- Square Buckle

- Agv Robot Chassis

- Industrial Robot

- Winding Machine

- Auto Feeder

- luggage belt

- fish farm feeder

- automatic fish feeder

- Gold Buckle

- Round Ring Buckle

- Bag Buckle

Recommended Products

- Automatic water cooling tower machine for induction heating furnace

- Water cooling tower machinery for induction furnace

- Water cooling equipment for induction heater

- Water cooling tower machinery induction heater furnace

- pup jonit and swivel joint

- 2 7/8"-5"VBR and 4 1/2"-7" VBR ram assembly manufactuer

- GK,GX,Shaffer packing element manufactuer

- glass tube China manufactuer

- choke manifold factory China

- ESP cable penetrator Artificial Lift equipment

- coflexip hose

- Top Drive Services varco BPM jinghong TPEC

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tom

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Tom

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile