foaming machine *** water circulation cooling machine

≥1 Unit

You May Like

-

ultra-fine grinder cooling system (low-temperature air conditioner)

-

ultra-fine grinder cooling device (air cooler)

-

battery pack pack high and low temperature liquid (water) cooling aging tester system -40°c to 100°c

-

cbe-14alch kawamoto suster battery pack liquid cooling machine water cooling test system

-

liquid cooling (water cooling) testing system device -40°c to 100°c, model cbe-14alch

-

0-degree air outlet industrial air cooler, used in supporting with large crusher

Product Description

Brief IntroductionThe most suitable cleaning temperature for the water cleaning liquid is 40 - 60°C. Especially in cold weather, if the temperature of the cleaning liquid is low, the cavitation effect is poor and the cleaning effect is also poor. Therefore, some cleaning machines have heating electric wires wound around the outside of the cleaning tank for temperature control. When the temperature rises, cavitation is likely to occur, so the cleaning effect is better. When the temperature continues to rise, the gas pressure in the cavitation bubble increases, causing the impact sound pressure to decrease, reflecting the multiplicative effect of these two factors.

Taking all the above factors into consideration, Shenzhen Chuanbenster Refrigeration Equipment Co., Ltd. can reduce the temperature of the cleaning agent, condense the gaseous cleaning agent, and effectively prevent the volatilization of the cleaning agent

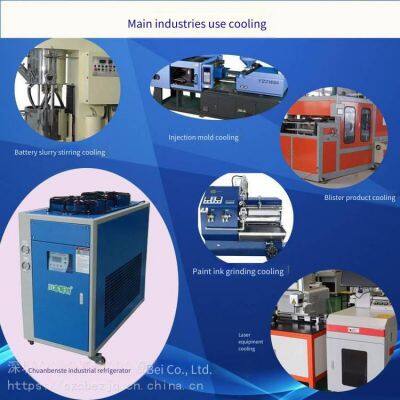

3, in the plastics industry

injection molding, extrusion molding, blow molding, compression molding, blown film and calendered film. Standard industrial models are applicable to the above industries.

A. Cooling of injection molding molds

After the plastic pellets are heated and melted, they are injected into the mold. After solidification, the mold is opened and the formed plastic workpiece is ejected. During continuous production, it is necessary to cool the mold to shorten the plastic solidification time, improve the workpiece dimensional accuracy, forming quality and surface quality.

Required chilled water temperature: 6 - 18°C

Required chilled water temperature difference: ±2K or ±0.5K

The refrigeration capacity of the unit is related to the injection volume of the injection molding machine (usually called "ounce"). The larger the injection volume, the greater the required refrigeration capacity.

Injection molding machines are usually nominalized by clamping force. This requires converting tons to ounces, but tons and ounces do not have a one-to-one correspondence. The following conversion table is only for general conversion relationships and has certain upper and lower deviations.

4.Laser

All components of the refrigeration system adopt *** components. The water tank is made of coil-free pure stainless steel material, with a long-lasting and stable refrigeration effect. The temperature control accuracy is ±1°C;

With ***, low temperature display and signal output protection, and configured with normally open and normally closed outputs for selection;

The chilled water circulation system uses stainless steel multi-stage pumps and stainless steel pumps, connected with PVC materials, without the worry of rust, and pure water or deionized water can be used directly;

In the laser (laser) system, the laser generator, beam controller and electric control cabinet may all require additional cooling. The required chilled water temperature is usually between 15...22°C, and the required chilled water accuracy is usually ±1K or ±2K. Some equipment may require ±0.5K. In addition, some equipment has certain requirements for the conductivity of chilled water, *** etc. Therefore, the requirement for water quality is very high, and the pipes are made of stainless steel or PVC pipes. For special applications in the laser system, Shenzhen Chuanbenster Refrigeration Equipment Co., Ltd. can design industrial models to meet different requirements. Laser chillers are mainly applied to laser marking machines, laser engraving machines, laser welding machines, laser coding machines, laser cutting machines and other laser processing equipment. It can *** control the temperature required by the laser equipment, thus *** the normal operation of the laser equipment. Product features: Adopt imported American brand and Japanese Panasonic compressors, with built-in safety protection, low noise, power saving ***, to increase the service life of the equipment. Adopt high-efficiency finned condensers, with ***, plus high-efficiency external rotor fans, and there is no need to connect to the cooling tower system and other advantages. Adopt industrial pure titanium and open stainless steel water tank evaporators, with built-in water level protection and other devices to facilitate customers to add water and clean and maintain. Adopt stainless steel multi-stage pumps and water pipes to prevent the generation of solids and other metal impurities during the transportation of pure water. Adopt a liquid crystal display microcomputer controller, which can *** control the water temperature, with a Chinese interface, simple and convenient operation, and *** control functions. Adopt German Schneider electrical products, with a complete electrical protection system. Adopt an electrostatic spraying shell, which is beautiful and generous. The outer panel adopts a quick installation form, which is convenient for use and maintenance.

5. Electroplating Industry- Oxidation Industry

Characteristics of electroplating industry products: Shenzhen Chuanbenster Refrigeration Equipment Co., Ltd. manufactures products for the industry. To meet the corrosion requirements of the electroplating, oxidation, and electrophoretic coating industries, a heat exchanger made of titanium material is specifically designed, which can safely provide highly efficient assistance in production!

1. In the production process of modern industrial machinery, precise temperature control is a major factor in promoting productivity and product quality. Therefore, the market competitiveness of the manufacturing industry depends on assistance in reducing temperature, improving product quality, and increasing profits.

2. In the electroplating, oxidation, and electrophoretic coating industries, it helps to stabilize metal and non-metal ions, enabling metal ions to quickly adhere to electroplated parts, oxidized parts, and electrophoretic parts. This not only increases density and smoothness but also reduces the number of electroplating times and improves productivity.

6. Reaction Kettle Industry

Characteristics of reaction kettle industry products: Adopt medium and low-temperature compressors from Europe, a fully automatic computer controller, a high-efficiency heat exchanger, and also use international well-known brand accessories. The temperature control range is from -40°C to -80°C, and it is widely applied in fine chemicals, food additives, deep corn processing (starch), pharmaceuticals, and pharmaceutical storage, etc.

7. Water-cooled Screw Type Industry

Characteristics of water-cooled screw type products:

(1) The most efficient semi-hermetic compressor. The heart of the unit - an imported well-known screw compressor, its 5:6 high-efficiency screw rotor compressor, has an energy efficiency 20 - 30% higher than that of ordinary compressors. It operates reliably, is easy to maintain, has excellent capacity control, and wide applications.

The latest asymmetric rotor tooth profile.

Four-stage or stepless capacity control system.

Built-in differential pressure oil supply and lubrication system.

Low vibration and low noise.

(2) The microcomputer accurately controls the temperature. The microcomputer controller of the unit uses a large-screen dot matrix liquid crystal display, with a good all-Chinese man-machine dialogue interface to achieve full-function automatic control. The liquid crystal display screen instantly shows the working status of the machine, ensuring that the unit runs in the best state. Its touch panel has good sealing, is waterproof, dustproof, corrosion-resistant, and has a long button life. Stepped and stepless energy control, used in general air conditioning systems, equipped with 100%, 75%, 50%, 25% stepped energy control systems. This ensures that the unit achieves the greatest energy-saving effect under partial load. However, if precise control of the water temperature is required, all models can be equipped with a stepless energy control system according to user requirements.

(3) It runs stably. The heat exchanger uses high-efficiency corrugated pipes, combined with a high-efficiency screw compressor, ensuring the stable operation of the unit. The most reliable protection and auxiliary components.

(4) The unit has the following components to prevent any operating failures: Compressor protection timer, overcurrent relay, compressor motor temperature sensor, anti-freezing thermostat, sight glass, oil heater, compressor reverse phase protection relay, high and low-pressure protection, exhaust high-temperature protection, safety valve, fusible plug.

8,Coating Machine Industrial

Medium-frequency vacuum coating machines generally need to be equipped with a cooling device for the coating machine (mainly cylindrical targets).

Medium-frequency equipment must be supplied with cooling water because of its high-frequency and large current. When current flows in a conductor, there is a skin effect.

The charge will accumulate on the surface area of the conductor, which makes the conductor heat up. Therefore, a hollow tube is used as the conductor, and water is added in the middle for cooling.

9.Low-temperature type Industrial(Minus 5 - Minus 40 degrees Celsius)

High cooling capacity, using imported compressors of world-renowned brands. Excellent low-temperature performance and reliability. The product is designed according to the characteristics of industrial applications, with a built-in low-temperature circulating water pump and a stainless-steel cooling water tank, making it extremely convenient to use. All materials in contact with water are made of anti-corrosion materials to effectively prevent rust and corrosion. The microcomputer LED digital display controller has functions such as temperature display, set temperature, automatic adjustment of chilled water temperature, and compressor delay protection. Electrical components such as contactors and relays of well-known brands are used, and a complete set of indicator lights and switches are equipped, making the operation clear at a glance. There is a built-in electronic water level indicator and alarm. Operators can grasp the water level of the cooling water tank through the control panel and take timely measures. The modular design ensures the safety and independence of each compressor system. Even if one system has problems, it will not affect the normal operation of other systems.

For application details, please consult the sales staff of Shenzhen Chuanbenster Refrigeration Equipment Co., Ltd.

{Maintenance and CareIf there are any abnormalities as above, please notify Shenzhen Chuanbenster Refrigeration Equipment Co., Ltd. as soon as possible to send maintenance personnel to handle it.

{After-sales Service Commitment

Contact Us

- Shenzhen Chuanbenst Refrigeration Equipment Co., Ltd.

- Contact nameLuo Yongquan Chat Now

- AddressNo. 1, Hengling Middle Road, Nianfeng Community, Pingdi Sub-district, Shenzhen, Guangdong

Product Categories

New Products

-

kawamoto brand cbe-84af industrial cold air blower crusher***

-

chiller for powder mill cooling***, chuen ben brand crusher*** air conditioner

-

large-scale traditional chinese medicine crusher *** air conditioner (air outlet at 0 degrees)

-

warm powder coatings】 【industrial air cooler (air chiller)

-

powder coating cooling equipment (industrial air cooler)

-

industrial air cooler for large-scale crushing supporting

-

powder equipment *** industrial air cooler with large air output

-

cooling industrial air cooler air conditioning equipment supporting kawamoto sato flour mill

-

industrial cooling fan special for crusher

-

special screw chiller for injection molding machine

-

hanzhong compressor screw chiller, single screw refrigeration unit

-

maintenance of screw chiller, parameters of screw chiller

-

industrial circulating water screw unit, kawamoto brand screw unit

-

working principle diagram of water-cooled screw unit

-

manufacturer wholesale direct sale water circulation screw chiller

-

screw refrigeration unit, maintenance of water-cooled screw machine

-

kawamoto brand water-cooled twin screw chiller***

-

water-cooled screw unit *** solution

-

high-efficiency energy-saving water-cooled circulating water screw chiller

-

selection of water-cooled screw chiller units

-

high-configuration water-cooled industrial screw chiller (produced by kawamoto)

-

centralized cooling water supply screw refrigeration unit for injection molding machine (screw-type circulating cooling unit)

-

brine screw chiller, screw industrial refrigeration unit

-

twin-head screw refrigeration unit, single-head water circulation refrigeration unit

Popular Searches

- air cooler

- cooling system

- heat exchanger

- water chiller

- industrial chiller

- refrigeration equipment

- screw chiller

- air conditioner

- cooling machine

- cooling equipment

- hvac

- industrial refrigerator

- air cooled water chiller

- water cooled chiller

- Industrial Water Chiller

- Chiller Machine

- Absorption Chiller

- Screw Water Chiller

- Glycol Water Chiller

- Water Cooled Screw Chiller

- Air Cooled Screw Chiller

- Air Cooled Industrial Chiller

- Air Cooled Scroll Chiller

- glycol chiller

- Chiller Unit

- Air Cooled Glycol Chiller

- oil chiller

Recommended Products

- 2025 New AC240V EC0-10V Smart Thermostat for School Use Knob Touch Button Fan Coil Unit (FCU) with 2/4 Pipes Energy Saving Design

- WIFI Remote Temperature Control Smart Knob-type Thermostat 2/4 Pipes for Smarthouse FCU Controller

- WIFI Remote Temperature Control Smart Knob-type Thermostat 2/4 Pipes for Smarthouse FCU Controller

- 2025 New WIFI Remote Temperature Control Smart Thermostat 2/4 Pipes for Smarthouse FCU Controller Modbus Thermostat

- HRV ERV Controller WIFI TUYA APP Real-Time CO2 and PM2.5 for AHU Units Ventilation System Controller

- TUYA APP For Home Ventilation System HVAC HRV ERV with CO2 PM2.5 VOC PM10 Home HVAC System Controller

- Intelligent HVAC System Smart Controller Used for AC EC DC Fans LCD Color Screen TUYA APP RS485 Fresh Air Dehumidification Controller

- Smart Controller For HVAC System Energy Recovery Ventilation Home Ventilation System WiFi Thermostat HRV ERV Unit

- Capillary Tube Mats PLASTER ON GYPSUM BOARD Ceiling Installation

- Innovative Cooling Heating System Energy Saving Up Capillary Tube Mats

- Ceiling-Mounted Smart Ventilation System Controller HRV ERV CO2 PM2.5 VOC RS485 TUYA APP Modbus HVAC Controller

- WIFI Remote Temperature Control Smart Thermostat 2/4 Pipes for Smarthouse FCU Controller Smart Thermostat

Find Similar Products By Category

- Industrial Equipment & Components > Refrigeration Equipment > Industrial Air Conditioner

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Luo Yongquan

Hi there! Welcome to my shop. Let me know if you have any questions.

Luo Yongquan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile