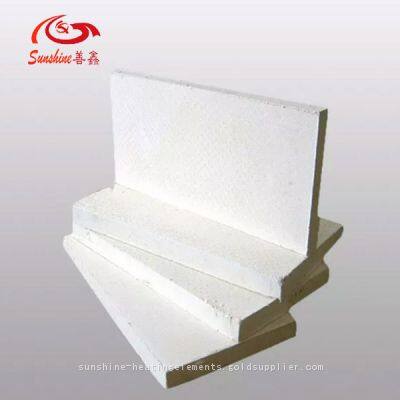

Home > Products > Ceramic Fiber Products > 1430C Ceramic Fiber Board Density 300kg/m3

1430C Ceramic Fiber Board Density 300kg/m3

- Qingdao

- T/T

You May Like

-

High Temperature 1600C 1800C Polycrystalline Mullite Insulation Fiber Board Using in Lab Oven Furnace

-

Tablero De Fibra de Mullita Policristalina de Alta Temperatura de 1800 °C

-

1800 Elementos Calefactores de Disiliciuro de Molibdeno (MoSi2) Para Hornos de Sinterización

-

1800C U Shape Electric Molybdenum Disilicide MoSi2 Industrial Heating Elements Using in Zirconia Electric Furnace Lab Furnace

-

SiC Silicon Carbide Heating Elements With Customizable Designs

-

Elementos Calefactores de Disiliciuro de Molibdeno MoSi2 en Forma de U de 1800 °C

Product Details

| Shape | Other, Ceramic fiber board | Usage | Thermal Insulation Coatings, High Temperature Insulating Material | |

| Kind | High Purity Ceramic Fiber | Temprature Classification | 1600℃, 1400℃, 1260℃ | |

| Chemical Composition: | SiO2, Al2O3, Other | Transport Package | Carton | |

| Trademark | SUNSHINE | Origin | China |

Product Description

Polycrystalline Mullite Fiber (PMF) is a novel super-light high temperature refractory fiber in the world, one of the whole Al2O3-SiO2 system ceramic fibers, with use temperature of 1800 degrees to 1700 degrees, 200 degrees to 300 degrees higher that that of fiber glass.

Polycrystalline mullite fiber (PMF) is currently at home and abroad the latest ultra-lightweight high-temperature fire resistant fiber, the whole system Al2O3SiO2 ceramic fibers in two different products, It can be widely used in metallurgy, machinery, electronics, ceramics, chemicals, aerospace and other high temperature industrial furnaces and other thermal equipment, lined with insulation.

In order to achieve energy efficiency increase, extend furnace life, the purpose of improving the working environment. Appearance white, smooth, soft, flexible, just like cotton.

Characteristic

It is characterized in white appearance, smoothness, softness and elasticity, just like pledget. PMF is a polycrystalline mullite fiber in the existing form of mullite crystalling phase, with a unique structure, complicated manufacturing process and high technical content.

High temperature stability to 1600-1800C

Ideal for use as furnace insulation in sintering, heat treating and chemical thermal process systems

Non-Flammable

Excellent thermal shock resistance

Resistance to most chemical attack; it has excellent stability in acid metal slags and is insoluble in most acids

Resistance to oxidation and attack by furnace atmospheres

Resistance to abrasion

Good electrical resistivity

Excellent thermal stability

Can be used as insulation packing in furnace spaces and around furnace sight tubes & ports

Fill in expansion joints and masonry cracks inside of furnaces.

Different types

| Ceramic fiber board | SS1050C-RBD | SS1260 ST-RBD | SS1260 HP-RBD | SS1350 HA-RBD | SS1430 Zr-RBD | SS1600 PCF-RBD | SS1700 PCF-RBD | SS1800 PCF-RBD | |

| Max Service Temperature(℃) | 1050 | 1260 | 1260 | 1350 | 1430 | 1600 | 1700 | 1800 | |

| Density (kg/m³) | 220/250/280/300/320/350/380/400 | 400/450/500/550 | |||||||

| Linear hrinkage(%) (After burning)(24h) | ≤3.0 950℃ | ≤3.0 1050℃ | ≤3.0 1100℃ | ≤3.0 1200℃ | ≤3.0 1300℃ | ≤1.0 1450℃ | ≤1.0 1550℃ | ≤1.0 1650℃ | |

| (MPa)Modulus of rupture | ≥0.3 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.6 | ≥0.6 | ≥0.6 | |

| (%)Loss on ignition | ≤8.0 | ≤4.0 | |||||||

| Thermal conductivity rate(W/m.k) | 400℃ | 0.08 | – | – | – | – | – | – | – |

| 600℃ | 0.12 | 0.12 | 0.12 | 0.12 | – | – | – | – | |

| 800℃ | 0.16 | 0.16 | 0.16 | 0.16 | 0.16 | 0.17 | 0.17 | 0.17 | |

| 1000℃ | – | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | |

| Chemical Composition(%) | Al2O3 | ≥37 | ≥41 | ≥43 | ≥45 | ≥37 | ≥65 | ≥70 | ≥72 |

| Al2O3+SiO₂ | ≥97 | ≥97 | ≥98 | ≥98 | ≥84 | ≥99 | ≥99 | ≥99 | |

| ZrO₂ | – | – | – | – | ≥11 | – | – | – | |

| Others | ≤3.0 | ≤3.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| Standard size(L*W*T)mm | 1200/600*1000*(6-105),1200*500*(6-105) | 1000/900*600*20-150 | |||||||

| Package | Cartons or Pallets | Wooden | |||||||

| Other sizes of products and packages are available as required. | |||||||||

| Recommended using temperature:In oxidizing or neutral atmosphere,100~250℃Recommended usingtemperature:In oxidizing or neutral atmosphere,100∽250℃lower than the maximum service temperature,In reductive atmosphere,200~350℃ lower than the maximum service temperature. | |||||||||

Welcome to Contact:

Contact Us

- Henan SUNSHINE High Temperature Materials CO., LTD

- Contact nameJessie Yu Chat Now

- AddressERQI DISTRICT, Zhengzhou, Henan, China

Product Categories

New Products

-

Molybdenum Disilicide MoSi2 Heating Elements With Exceptional Conductivity, Corrosion Resistance for High-temperature Lab Furnace Applications.

-

SiC Silicon Carbide Heating Elements Accessories Flexible Braided Strips

-

Flexible Aluminium Connection Straps and Clips Use for SiC Heating Elements SiC Heater Accessories

-

SiC Heating Elements Accessories Aluminum Braided Straps With High Quality

-

1800C Polycrystalline Mullite Insulation Fiber Board Thickness 100mm With High Quality

-

Laboratory Muffle Furnace Molybdenum Silicide Heating Elements (MoSi2) Heater With High Temperature

-

Dumbbell Straight Shaped Heating Elements MoSi2 Heating Elements High Temeprature Furnace Resistor

-

SGR Type Double Spiral SiC Silicon Carbide Heating Elements Max Temperature 1625 ℃ for Dental Lab Sintering Furnace

-

SGR Type Double Spiral SiC Silicon Carbide Heating Element Single Sided Spiral up to 1625°C

-

Super 1800 C U-Shape Furnace Molybdenum Silicide Heating Elements (MoSi2)

-

Customized Size Molybdenum Disilicide Heating Elements (MoSi2)

-

SG Type SiC Silicon Carbide Heating Elements Heater (Single Spiral)

-

High Temperature Electric SiC Silicon Carbide Heating Element Single Thread Heater Resistors for Furnace

-

El Carburo de Silicio (SiC) Los Elementos 1500°

-

Elementos Calefactores de SiC Tipo SG (Epiral Simple) 1500

-

High Quality 1800C Polycrystalline Mullite High Alumina Fiber Board With Factory Price

-

1600C Double Spiral Type SiC Heating Elements Silicon Carbide Heating Rod

-

High Quality Electric Furnace MoSi2 Heating Elements Super 1700, 1800, 1900

-

1850C U Shape Molybdenum Disilicide (MoSi2) Heating Elements for Dental Zirconia Sintering Furnace

-

Type RR , Silicon Carbide Heating Elements Rod Straight Shape

-

ED Type SiC Silicon Carbide Heating Elements Furnace Heater

-

ED Type, Straight Rod Type Resistance Silicon Carbide SiC Heating Elements for High Temperature

-

1800C Polycrystalline Mullite Insulation Fiber Board for High Temperature Industry and Lab Furnace

-

High Temperature Furnace Insulation Board 1800C Polycrystalline Mullite Fiber Board High Aluminum Board for High Temperature Lab Furnace and Oven

Popular Searches

Recommended Products

- 1800C Polycrystalline Mullite Alumina Fibre Insulation Fiber Board Use for Customize Furnace Chamber

- Thermal Insulation Material, Insulation Cotton, Insulation Board

- Thermal Insulation Material Ceramic Fiber Paper

- Ceramic Fiber Felt Ceramic Fiber Tape

- Ceramic Fiber Yarn Ceramic Fiber Module Ceramic Fiber Bulk

- Ceramic Fiber Paper Ceramic Fiber Cloth Ceramic Fiber Rope

- Alumina Silica Wool Ceramic Fiber Blanket Ceramic Fiber Board

- Ceramic Fiber Ceramic Wool Refractory Fiber

- 1800°C Polycrystalline Alumina Fiber Insulation Board for Lab Furnace Laboratory Oven

- High Temperature Furnace Insulation Board 1800C Polycrystalline Mullite Fiber Board High Aluminum Board for High Temperature Lab Furnace and Oven

- 1800C Polycrystalline Mullite Insulation Fiber Board for High Temperature Industry and Lab Furnace

- High Quality 1800C Polycrystalline Mullite High Alumina Fiber Board With Factory Price

Find Similar Products By Category

- Chemicals > Inorganic Fiber > Ceramic Fiber

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jessie Yu

Hi there! Welcome to my shop. Let me know if you have any questions.

Jessie Yu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile