Polyamide PA Nylon Powder Coating Supplier PA11 PA 12 Power

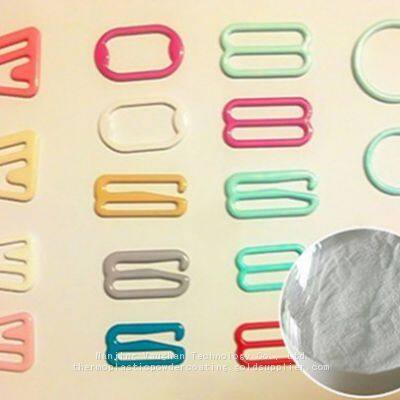

Nylon ( Polyamide, PA ) powder coating is mainly used in the fields of transmission shaft, spline shaft, door slides, seat springs, engine hood support bars, seat belt buckles, storage boxes, printing roller, ink guide roller, airbag shrapnel, anti-loose screws, underwear accessories, and hanging tool cleaning baskets, dishwasher basket,ect. It provides wear resistance, noise reduction, safety, environmental protection, and energy-saving functions. This product has exclusivity and cannot be replaced by other general-purpose plastics.

The application process of polyamide nylon powder coating is relatively straightforward. It can be applied using electrostatic spraying or fluidized bed dipping, depending on the specific requirements of the project. The powder is first applied to the surface of the substrate and then cured in an oven at a specific temperature. This curing process fuses the powder particles together, forming a continuous and homogeneous coating.

| Category | Item | Specification | Standard/Notes |

| Powder Properties | Specific Gravity | 1.05 g/cc | - |

| Bulk Density | 0.500 g/cc | - | |

| Water Absorption | ≤ 1.0 % | Test time: 86400 sec | |

| Particle Size | 100 - 130 µm | - | |

| Coating Properties | Hardness, Shore D | 70 | Complies with ISO 868 |

| Impact Test | ≥ 2.00 J | Complies with ASTM G14 | |

| Taber Abrasion | 15 mg/1000 Cycles | Complies with ISO 9352 | |

| Dielectric Strength | 30.0 kV/mm | Complies with ASTM D149; Test thickness: 0.350 - 0.450 mm | |

| Melting Point | 183 - 188 °C | Complies with ISO 1218 | |

| Vicat Softening Point | 181 °C | Complies with ISO 306 | |

| Recommended Coating Thickness | ≤ 300 microns | - | |

| Color | Grey | - | |

| Covering Efficiency | 0.36 kg/m² | - | |

| Covering Efficiency (by Thickness) | 300 µm | - | |

| Salt Spray Test | Good adhesion after 2000 hours | Complies with ISO 9227 | |

| Packing and Storage | Packing Specification | 20 kg/bag | - |

| Storage Conditions | Store in a clean, dry area; temperature <40℃; avoid sunlight | - | |

| Shelf Life | 2 years | - | |

| Post-Expiration Use | Usable if no quality issues are found after testing | - | |

| Mixing Requirement | PECOAT®PE powder must not be mixed with powders from other suppliers | - |

Send Inquiry to This Supplier

You May Also Like

-

High-Gloss Nylon Powder Coating for Nylon Coated Buckles for UnderwearUS$ 5 - 6MOQ: 25 Kilograms

-

Food-Safe Nylon PA11/PA12 Powder Coating for Dishwasher Baskets,Corrosion-ResistantUS$ 5 - 6MOQ: 100 Kilograms

-

Customizable Nylon PA11/PA12 Powder Coating for Dishwasher BasketsUS$ 5 - 6MOQ: 100 Kilograms

-

Nylon PA11 PA12 Powder Coating for Wear-Resistant Bra Underwire ProtectionUS$ 5 - 6MOQ: 100 Kilograms

-

Nylon PA11 PA12 Powder Coating for Bra Underwire Steel Wire EndsUS$ 5 - 6MOQ: 100 Kilograms

-

Bra Steel Ring End Coating Nylon PA11 PA12 Powder Coating BULE White ColorUS$ 5 - 6MOQ: 100 Kilograms

-

Teflon PTFE Micro Powder Supplier. PTFE Super Fine Powder for Lubricating OilUS$ 5 - 6MOQ: 20 Kilograms

-

PVC Plastisol Coating Supplier Plastisol Liquid Dip CoatingUS$ 2 - 3MOQ: 250 Kilograms

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentNegotiableMOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionNegotiableMOQ: 1 Piece