Pellet Machine for Charcoal Grill

Pellet Machine for Charcoal Grill Introduction:

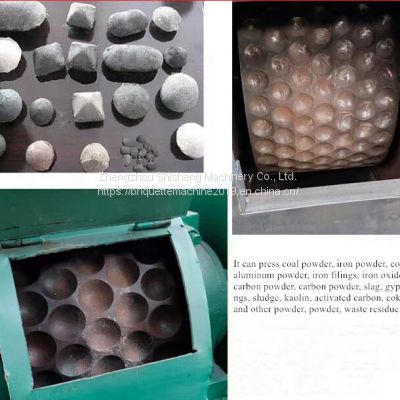

(1) Pellet Machine for Charcoal Grill, mainly used in the production of press sludge, directly into the furnace to smelt and increase the added value.

(2) Any metallurgical industry wastes which all need to be smelted in the furnace,have to be completed by ball press machine, such as furnace dust, mud, oxide iron, steel slag, iron concentrate, aluminum ash, silicon manganese and so on.

(3) Pellet Machine for Charcoal Grill is widely used in metallurgy, refractories, power plant, chemical industry, energy, transportation, heating and other industries, has good economic and social benefits.

Pellet Machine for Charcoal Grill Customer Cautions:

(1) The particle size of the raw material should be between 0-5mm.

(2) Pellet Machine for Charcoal Grill can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

(3) The feeding of whole production line should be stable, even, ensure workloads of dry powder briquette machine stable, to get high efficiency of production.

Pellet Machine for Charcoal Grill Working Principle:

(1) This series of Pellet Machine for Charcoal Grill will pass the powder on to the two pressure roller through the reducer.

(2)The two sides and roll rotation, in both the rotating roll, natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger.

(3)When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials becomes a finished product from the powder ball.

Technical Parameter:

Model: KF1450-850-350

Reducer: ZS1450

Ratio: 63

Roller Size: 850*350mm

Main Shaft Speed: 7-9r/min

Matched Power: 132kw

Capacity: 15-16t/h

Pressure Type: Constant Pressure/Hydraulic Pressure

Roller Material: 65Mn, 9Cr2Mo, high chrome alloy

XM Series Coal Briquetting Machine

| Model | Reducer | Ratio | Roller Size(mm) | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Constant Pressure |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Constant Pressure/Hydraulic Pressure |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | |

| XM750 | ZQ1000 | 40.17 | 750*570 | 9-11 | 90 | 13-14 | |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | |

| Remarks: Above capacity is based on material specific gravity 0.8, briquette size: φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo | |||||||

| According to different material adjust machine parameter to meet customer production | |||||||

KF Series Mineral Powder Briquetting Machine

| Model | Reducer | Ratio | Roller Size | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| KF500-371-280 | ZQ500 | 40.17 | 370*280 | 8-10 | 11 | 6.5-7.5 | Constant Pressure/Hydraulic Pressure |

| KF650-500-300 | ZQ650 | 40.17 | 500*300 | 8-10 | 37 | 8.5-9.5 | |

| KF850-650-300 | ZQ850 | 40.17 | 650*300 | 8-10 | 55 | 10.5-11.5 | |

| KF1250-750-350 | ZS1250 | 50 | 750*350 | 7-9 | 110 | 13.5-14.0 | |

| KF1450-850-350 | ZS1450 | 50 | 850*350 | 7-9 | 132 | 15.0-16.0 | |

| KF560-1000-350 | ZSY560 | 50 | 1000*350 | 7-9 | 150 | 17.0-20.0 | |

| Remarks: Above Capacity is based on material specific gravity 2, briquette size:φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo. | |||||||

| According to different material adjust machine parameter to mmet customer production | |||||||

YHG Series Dry Powder High Pressure Briquetting Machine

| Model | YHG-0.5 | YHG-1.5 | YHG-3.0 | YHG-5.0 | YHG-8.0 | YHG-10.0 |

| Roller Diameter(mm) | φ299 | φ367 | φ522 | φ738 | φ760 | φ858 |

| Roller Width(mm) | 180 | 183 | 196 | 210 | 225 | 300 |

| Capacity(t/h) | 0.5 | 1.2-1.4 | 2.5-3.0 | 4.5-5.5 | 7.5-8.5 | 8.0-9.5 |

| Main Reducer | ZQ650 | ZQ850 | ZS1250 | ZS1450 | ZS1650 | ZS1650 |

| Main Motor | 18.5 | 37 | 55 | 75 | 90-110 | 110-132 |

| Pre-pressure Motor(kw) | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 |

| Pre-pressure Reducer | WHC-125 | WHC-160 | WHC-200 | WHC-210 | WHC-210 | WHC-250 |

| Remarks: Above capacity is based on material specific gravity 1.3, briquette size: φ35*30*20mm | ||||||

| Roller material adopts 9Cr2Mo | ||||||

| Pre-pressure motor is speed motor | ||||||

Send Inquiry to This Supplier

You May Also Like

-

How to Make Pellets From PowderUS$ 3500 - 4000MOQ: 1 Set

-

How to Make Pellet PowderUS$ 5500 - 7500MOQ: 1 Set

-

Pelletising ProcessUS$ 5500 - 6500MOQ: 1 Set

-

Pelletising PlantUS$ 5500 - 7500MOQ: 1 Set

-

Pelletising MachineUS$ 3500 - 4000MOQ: 1 Set

-

Cold Forming Press MachineUS$ 3000 - 5000MOQ: 1 Set

-

Pellet Forming MachineUS$ 3500 - 5000MOQ: 1 Set

-

How do Pellets FormUS$ 3000 - 3500MOQ: 1 Set

-

How is Clay Pellets FormedUS$ 3000 - 5500MOQ: 1 Set

-

Machine for Pellet FormUS$ 3000 - 3500MOQ: 1 Set