Charcoal Pellet Making Machine Price/Charcoal Pelletizing Machine

charcoal pellet making machine price/charcoal pelletizing machine

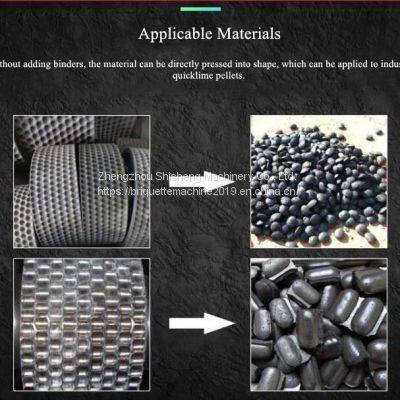

The charcoal pellet making machine price/charcoal pelletizing machine is mainly used for pressing powdery materials that are difficult to form. It is characterized by high forming pressure, adjustable host speed, and equipped with a screw feeding device. Since 2002, relevant institutes of the metallurgical industry have conducted scientific research and adopted a high-pressure powder briquetting machine to press the kiln powder into pellets for smelting. Some foreign steel mills and my country's Baosteel and Anshan Iron and Steel have already used it.

(3) The small charcoal pellet making machine price/charcoal pelletizing machine has 1-6T/H output briquettes production. The size and shape of briquettes is customized but commonly be produced into 25-60mm diameters, the shape shall be oval, round, pillow, square, etc.

(4) Different materials will be designed into different production line work-flow, customer needs to tell us of the materials' moisture, particle size, yield, briquettes size, shape, some special circumstances maybe need auxiliary equipment such as other crusher, mixer, screen mesh, vibration sieve, binder feeder, briquette drying machine, etc.

XM Series Coal Briquetting Machine

| Model | Reducer | Ratio | Roller Size(mm) | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Constant Pressure |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Constant Pressure/Hydraulic Pressure |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | |

| XM750 | ZQ1000 | 40.17 | 750*570 | 9-11 | 90 | 13-14 | |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | |

| Remarks: Above capacity is based on material specific gravity 0.8, briquette size: φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo | |||||||

| According to different material adjust machine parameter to meet customer production | |||||||

KF Series Mineral Powder Briquetting Machine

| Model | Reducer | Ratio | Roller Size | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| KF500-371-280 | ZQ500 | 40.17 | 370*280 | 8-10 | 11 | 6.5-7.5 | Constant Pressure/Hydraulic Pressure |

| KF650-500-300 | ZQ650 | 40.17 | 500*300 | 8-10 | 37 | 8.5-9.5 | |

| KF850-650-300 | ZQ850 | 40.17 | 650*300 | 8-10 | 55 | 10.5-11.5 | |

| KF1250-750-350 | ZS1250 | 50 | 750*350 | 7-9 | 110 | 13.5-14.0 | |

| KF1450-850-350 | ZS1450 | 50 | 850*350 | 7-9 | 132 | 15.0-16.0 | |

| KF560-1000-350 | ZSY560 | 50 | 1000*350 | 7-9 | 150 | 17.0-20.0 | |

| Remarks: Above Capacity is based on material specific gravity 2, briquette size:φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo. | |||||||

| According to different material adjust machine parameter to mmet customer production | |||||||

Send Inquiry to This Supplier

You May Also Like

-

Resistant To Corrosion Box Feeder Suitable For Chemical IndustryUS$ 3500 - 5500MOQ: 1 Set

-

High Productivity Feed Constant Suitable For Chemical IndustryUS$ 3500 - 5500MOQ: 1 Set

-

Resistant To Corrosion Box Feeder Suitable For Chemical IndustryUS$ 3500 - 5500MOQ: 1 Set

-

Simple Operation Grinding Wheel Mixer High Temperature ResistanceUS$ 3500 - 5000MOQ: 1 Set

-

Run Smoothly Mixing Machine Simple OperationUS$ 3500 - 5000MOQ: 1 Set

-

Easy Maintenance Wheel Mixer Simple OperationUS$ 3500 - 5000MOQ: 1 Set

-

High Yield Wheel Mixer Large Volume Of TransportUS$ 5000 - 8000MOQ: 1 Set

-

Easy Maintenance Wheel Mixer Not Easily CorrodedUS$ 8000 - 10000MOQ: 1 Set

-

Easy Maintenance Wheel Mixer Large Volume Of TransportUS$ 5000 - 6500MOQ: 1 Set

-

Easy Maintenance Wheel Mixer Not Easily CorrodedUS$ 3500 - 4000MOQ: 1 Set