Welded Lamination

- PayPal

Product Description

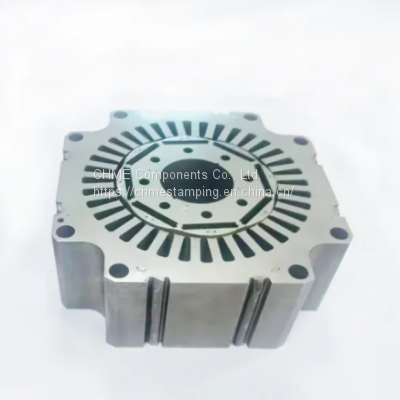

Welded Lamination

Product origin: guangdong

15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Describe | Welded lamination |

Types Of | Stator and rotor Core (stator rotor core), Welding (welding) |

Application | motor |

Processing | stamping |

Material | Silicon steel |

Weight Range | 0.5-100Kg |

Design Support | AutoCAD, Solidworks, PDF |

Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to Motor

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001, IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, Equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Stator and Rotor Lamination Welding Service

At CHME Components Co., Ltd., we specialize in the high-speed stamping and insulation coating business of motor core, including stator and rotor core production. We take pride in our stator and rotor lamination stack welding, which offers numerous benefits over other joining methods.

Our welding service provides versatility as it can work with a variety of materials and project types.Furthermore, our welding method forms a permanent bond between the stator and rotor lamination stacks, creating a joint that is far stronger than the components joined. We believe that welding is also a cost-effective process, especially when compared to other joining methods.

By partnering with our experienced welding provider, we can ensure the long-lasting integrity of your stator and rotor lamination stack welds. Trust CHME Components for all your stator and rotor core production needs. If you want to know more about stator and rotor lamination welding service, please feel free to contact us.

Why should you choose us?

At CHME Components Co., Ltd., we take pride in our high-speed stamping and insulation coating business of motor core, which includes the production of stator and rotor cores. Our state-of-the-art facility features cutting-edge equipment for stator and rotor lamination stack welding. Our welding process uses advanced technology to ensure precision and efficiency in welding stator and rotor cores.

Our experienced team of welders are proficient in welding a variety of materials ranging from silicon and cold rolled steel to other specialty metals. We believe that stator and rotor lamination stack welding is critical in ensuring the durability and performance of electric motors. Trust CHME Components Co., Ltd. to deliver superior quality stator and rotor cores with our advanced welding capabilities.

click to visit our website

More information:

https://www.xehealth.in

Contact Us

- CHME Components Co., Ltd.

Product Categories

| Stator and Rotor Core | Other Lamination | Welding | Deep Drawn Components |

Popular Searches

Recommended Products

- Metal Noise Barrier for Mechanical Equipment_Height 1m-20m

- Custom Sheet Metal

- Strong Welded Sheet Metal Structures

- Batch-produced Sheet Metal

- Deformation-resistant Sheet Metal Parts

- Cold-rolled Steel Sheet Metal Products

- Custom Electrostatic-sprayed Parts

- Corrosion-resistant Galvanized Sheet Metal

- CNC-bent Sheet Metal With Accurate Angles

- High-precision Laser-cut Components

- Precision Sheet Metal Cutouts & Holes for Electrical Control Cabinets

- Custom Sheet Metal Trays & Holders for Industrial Storage Systems

Find Similar Products By Category

- Industrial Equipment & Components > Industrial Customized Service > Sheet Metal Fabrication

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile