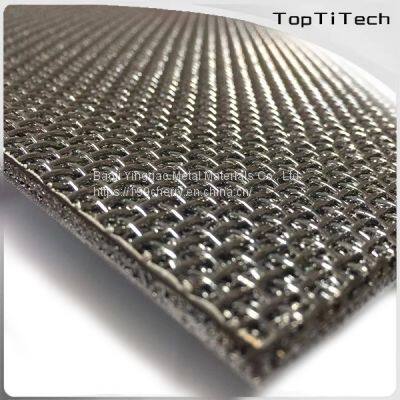

SUS316L five-layer sintered filter mesh is a widely used sintered mesh with standard structure. It is a new type of filter material made by stacking five layers of stainless steel sintered mesh in sequence and vacuum sintering. Generally, it is a five-layer structure, which is divided into five parts: protection layer, filter control layer, dispersion layer, support skeleton layer, and skeleton layer.

The standard five-layer sintered mesh filter has the characteristics of strong corrosion resistance, good permeability, high strength, easy cleaning and back cleaning, uniform filtration accuracy, hygienic and clean filter material, and no shedding of the wire mesh.

Sintered mesh has a wide range of applications, suitable for various filtration, separation, fluid bed, powder transportation, dust removal and explosion protection, and can be used in petrochemical industry, metallurgical industry, pharmaceutical industry, water treatment, food industry, environmental protection, machinery industry and other industries.

Product parameters

Standard thickness: 1.7MM

Standard material: stainless steel 304, 316, 316L

Standard size: 500*1000MM, 600*1200MM, 1000*1200MM

Note: On the basis of 5 layers of sintered mesh, add a layer of 12 mesh screen to become 6 layers of sintered mesh, with a thickness of 3.5MM, better pressure resistance.

Five-layer structure display

Features

1. Strong tensile strength and stiffness

It has a high mechanical strength, excellent processing, welding, and assembling capabilities, and is simple to use.

2. Consistent and uniform precision

It has a high mechanical strength, excellent processing, welding, and assembling capabilities, and is simple to use.

3. A wide range of applications

It can be utilized in temperatures ranging from -200 °C to 600 °C, as well as for acid and alkali filtration.

4. Outstanding cleaning performance

It has a good countercurrent cleaning effect, can be used frequently, and has a long service life (it can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

5. Excellent performance

Excellent mechanical performance, pressure and suction filtration, ability to satisfy various filtration needs, and ease of operation.

Application fields

1. In the machinery business, precise filtration of different hydraulic fluid lubricants;

2. Filtration, washing, and drying of materials in the pharmaceutical business; filtration and purification of various polymer melts in the chemical fiber film industry; filtration of various high-temperature and corrosive liquids in the petrochemical industry;

3. Use of fluidized plates in the steel sector and gas homogenization in the powder business;

4. Distributors of electrical appliances that are explosion-proof, etc.

Processing steps of stainless steel sintered mesh

1. Prepare materials. Stack the multi-layer mesh sheets that need to be sintered neatly according to the process requirements, and fix the four corners together by spot welding to form a sintered mesh;

2. Drain the net. Stack multiple sintered nets layer by layer on the material pallet, with an isolation layer between each sintered net, place a material pressure plate on the top of the sintered net, and place the stacked material pallet, sintered net and The material pressing plate is loaded into the sintering furnace;

3. Vacuum. Vacuum the sintering furnace.

4. Heating up. Heating by the heating device, when the temperature in the sintering chamber rises to 295-305°C, inject hydrogen into the sintering chamber to keep the pressure in the sintering chamber at 39-41Pa, continue heating to raise the temperature in the sintering chamber to 1200°C —1300℃;

5. Turn on the hydraulic mechanism to pressurize. Inject circulating cooling liquid into the cooling channel of the metal support rod, and start the hydraulic mechanism at the same time, so that the lower end of the heat-resistant ejector rod is pressed against the material pressure plate, and the pressure at the sintering network is 0.5-1.5 kg/cm2;

6. Heat preservation. Keep the pressure and temperature for 4-10 hours;

7. Cool down naturally and remove pressure. Turn off the heating device, remove the pressure at the same time, and slowly cool down to 1080°C - 1120°C;

8. Keep warm. At a temperature of 1080°C - 1120°C, keep warm for 1-2 hours;

9. Rapid cooling. Close the hydrogen inlet valve, let in cooling gas with a pressure of 1.9-2.1 atmospheres through the cooling gas inlet, and discharge it through the cooling gas outlet, so that the temperature drops rapidly to 280°C-310°C within 15 minutes;

10. Natural cooling. Stop the input of cooling gas, and rely on circulating cooling water to slowly cool down to 35°C-45°C;

11. Come out. The material pallet, sintering network and material pressing plate are removed from the sintering furnace, and after negative pressure vacuuming, rolling, leveling, cleaning, drying, inspection, and packaging, the finished stainless steel sintered mesh filter plate is made.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Pleated Filter for High Dirt CapacityUS$ 10 - 100MOQ: 1 Piece

-

Stainless Steel Powder Sintered FilterUS$ 5 - 100MOQ: 1 Piece

-

Sintered Wire Cloth LaminateUS$ 5 - 100MOQ: 1 Piece

-

Stainless Steel Pleated Filter CartridgeUS$ 5 - 100MOQ: 1 Piece

-

The Stainless Steel Filter Powder MetallurgyUS$ 10 - 100MOQ: 1 Piece

-

Multi-layer Metal Sintered Mesh Filter ElementUS$ 10 - 100MOQ: 1 Piece

-

SUS316L Powder Sintered Filter CartridgeUS$ 5 - 100MOQ: 1 Piece

-

Pleated Sintered Mesh Filter Improves Filtration EfficiencyUS$ 5 - 100MOQ: 1 Piece

-

Sintered Stainless Steel Porous Metal Filter TubeUS$ 5 - 100MOQ: 1 Piece

-

Muti-layer Stainless Steel Sintered Mesh Filter ElementUS$ 5 - 100MOQ: 1 Piece