Home > Products > steel belt granulator > Consol Steel Belt Cooler Granulation Granulator

Consol Steel Belt Cooler Granulation Granulator

- guangzhou

- T/T L/C

You May Like

Product Details

| Place of Origin | China | After-sales Service Provided | Engineers available to service machinery overseas | |

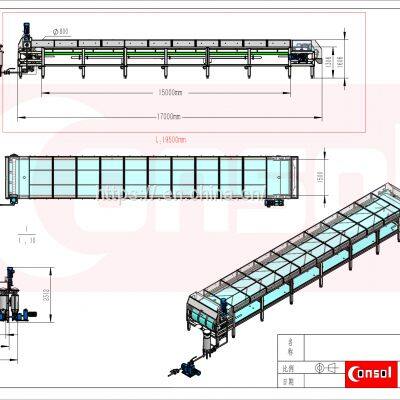

| Weight | 8t | Dimension(L*W*H) | 12000*2000*1800 | |

| Condition | New | Product Type | Other | |

| Power(W) | 7.5kw |

Product Description

consol International Granulation Engineering Co., Ltd (hereafter referred as consol) was established in 2008. Combining process, engineering experience and manufacturing capabilities, consolpositions itself in the market of advanced process solutions and process equipment. consolprovides advanced process technology and complete sets of equipment accordingto customer's specific requirements. Since 2008, consol focus on:

Calcium Chloride (CaCl2) Production Line (Granulation Line or Flaking Line)

Potassium Sulfate (K2SO4) Production Line

Calcium Hypochlorite Production Line

Hot Air Furnace & Heat Exchanger

Rotating belt Condensation Granulator (Chemical pastillator, Resin, wax, paraffin, resin, rosin pastillating machine, magnesium chloride pastillating equipment, and other hot melting material pastillating machines, with cooling steel steel belt conveyor type)

consol has cooperated with clients from Japan, Russia, Thailand, Indonesia, Pakistan, India, Jordan, Saudi Arabia and other countries. Our highly efficient and stable technology creates great value for our customers and has won high praise from our customers. Sustainable cooperation and partnershipis our goal, and sincerely hope to establish long-term mutual beneficiary relationship with more global customers. Customers' satisfaction is consol's final goal. Customers' sucess is our biggest honour.

consol avails one design center and two manufacturing sites, with a total covered surface in excess of 10000 m2. Proprietary equipment is manufactured in the two manufacturing facilities.

CONSOL STEEL BELT SYSTEM

STEEL BELT GRANULATION SYSTEM

PASTILLATOR FOR CHEMICAL INDUSTRYCONSOL MACHINERY, we can design, supply and install a complete cooling and solidification

system, appropriate to your particular product and process requirements,encompassing

everything from upstream feeding equipment and downstream handling and packaging to

process control.

Alongside this ability to engineer and manufacture a complete equipment, we offer all the

essential service and support necessary to ensure maximum productivity throughout the lifetime

of your equipment, wherever in the world your facility may be installed.

●Installation & start-up

●Maintenance & service

●Operator training

●Spare parts

●Process upgrades

Chemical processing ·Granulation systems for sulphur, wax, resin etc. ·Single belt and double belts flaking systems for resin, powder coat,sulphur, aluminum sulfate, etc. Strip former for hot melt adhesive. Food processing ·Steel belt coolers for chocolate ·Steel belt dryers for fruit and vegetables ·Steel belt sheet casting for chewing gum base. Available for various materialsThe CONSOL steel belt cooler is designed for in-line production of food and chemical products in shape of flakes,pastilles, strips or sheets, all of which can be formed and cooled

without additional process requirements. In other words, it is far more than just a belt cooler,enabling, products to be solidified,crystallized and formed as they are being conveyed.

The single belt cooling system Based on the CONSOL steel belt, the system is versatile and can be adapted to meet the needs of specific applications such as product thickness, temperature profile or processing times. How the CONSOL belt cooler works The molten product is loaded onto the steel belt via a suitable feeding device such as a pastillator,overflow weir or strip former. The heat released during cooling and solidification is eliminated through the steel belt with its excellent thermal conductivity. The steel belt is cooled by spraying cooling water from bottom of steel belt.The cooling water is collected in tanks and drained through an integral collecting pipe. Advantages at a glance ●Good operability/accessibility ●Economical operation with low maintenance costs ●Versatility produce pastilles,strips, strip granulate, flakes, plates,sheets, etc. ●Variable product thickness ●Zoned cooling allows product-specific temperature profiles Non-polluting Perfect cooling method The process is simple and performance proven. There is no contact between the cooling medium and product. The product

would not be polluted and the cooling medium can be re-used without expensive treatment. Where the cooling medium is not re-used (e.g,river water) the system provides the major economic advantage that the water.

can be drained without risk of environmental pollution. Compared with direct air cooling methods, the CONSOL steel belt cooler also has the benefit of no air pollution by dust, fumes or vapors.We are able to offer four standard feed systems to suit the requirements of different products, feed temperatures, viscosity, consistencies and desired shape at discharge. Overflow weir feeder flakes A heated overflow weir feeder is used to produce flakes and is suitable for products with viscosities up to 1000 mPas approx. Layer thicknesses ofI5 mm can be formed.

Double roll feeder - flakes The product is squeezed between two rollers to the required thickness and deposited on the steel belt. Cooling of the rollers means that the product is already in a pre-cooled condition when it reaches the steel belt, so this method is particularly suitable for melts with a high viscosity.

Granulator (1-30 mm diam.) A Granulation unit is ideal when the product must be with a precise shape and size, and must also be free flowing with minimal dust. No special is necessary at the discharge end.The outstanding advantages of solidification system make it the ideal feed unit for 70% of all applications.

Stripformer - strips A heated strip former deposits the product on the steel belt in a row of -strips, the width depending on the product and its viscosity. By means of a

granulator arranged at the end of the steel belt the strips are cut into

uniformly sized granules.After feeding devices, we have.developed a range of practical and economical discharge solutions to cope with the different requirements of a whole range of product types.

Scrapers Scrapers are usually used for products which

tend to stick to the steel belt.They consist usually

of a blade, which scrapes the product off the

steel belt at the end pulley.

Contact Us

- Consolsteel Belt

Product Categories

| steel belt granulator |

Popular Searches

- timing belt

- conveyor belt

- v belt

- stainless steel

- rubber conveyor belt

- rubber belt

- conveyor system

- steel cord conveyor belt

- chain conveyor belt

- wire mesh conveyor belt

- plate conveyor belt

- filter belt

- conveyor belting

- steel strip

- steel sheet

- steel coil

- sanding belt

- steel circle

- black steel strapping

- steel tape

- heat resistant conveyor belt

- steel band

- conveyor mesh belt

- stainless steel conveyor belt

- conveyor belt wire mesh

- plastic extruder

- hammer mill

- pelletizing machine

- recycling machine

- plastic recycling

Recommended Products

- Moulds for Manufacturing Plastic PP PE Particles for Underwater Pelletizing Extruder Granulation Die Plate

- Pelletizing Cutting Tools Blade Underwater Pelletizing Extruder Use Pelletizer Knives

- Underwater Granulation Extruder Spare Part Knife Holder for PP PE Granules Manufacturing

- Underwater Cutting Plastic Granules Line Use Pelletizer Knives

- Underwater Pelletizing System Extruder Use Die Plate for PP PE Granulation

- Industrial Cutting Blade Pelletizer Knives for Underwater PP PE Pelletizing Extruder

- Replace Spare Part for Underwater Pelletizing Extruder for PP PE Granulation Die Plate

- Plastic Granulating Hob Rotary Knife

- Polypropylene Polyethylene Granules Manufacturing Die Plate

- Cutting Tools Bi-Metal Knife Blade for Underwater PP PE Granulation

- Solid Carbide Pelletizer Knife for Underwater PP PE Granulation Twin Screw Extruder

- Cutting Knife Blade Pelletizer Knives for Underwater PP PE Granules Making Twin Screw Extruder

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Granulator

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile