Product Application

SJ series hdpe pipe extrusion line is widely used in fields of colliery slurry transportation, borehole high-pressure water supply, crude oil and natural gas transportation, water supply and drainage of daily life, power and chemical plants, and urban construction, etc.

Main parameters of ppr pipe making machine

Main Features

It is designed for producing 16-40mm ppr water and gas supply pipes. Our hdpe pipe extrusion line has feathure of high automatic, stable peformance, low consumtion.

ppr pipe making machine is applied to produce PE, PPR,PE-RT cold and hot water supply pipe. Equipped different molds, it also could produce PPR double -layer pipe, muti-layer pipe, PPR fiber glass reinforce pipe.

This ppr pipe making machine has advantage of easy operation, stable running, high output, and it is very popular home and abroad.

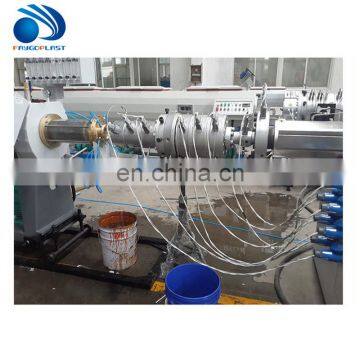

ppr pipe making machine includes: material charger, SJ series single screw extruder, pipe mould, vacuum calibration tank, spray cooling tank, haul-off, no-duct cutter, stacker, winder(for small pipes).

Extruding die: adopting latest designed die head with spiral distributing flow channel, built-in temperature controlling device which make the extrusion more evenly.

Vacuum calibrating tank: advanced water loop vacuum calibration, two vacuum chambers ensuring perfect roundness of the pipe, multi-section 6 meter water spraying tank, make sure cooling the pipe thoroughly, the main body of the tank made of stainless steel.

Haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter. It’s equiped metering device to count the length

Cutting machine: we have knife-lifting cutter and planetary cutter.

Controlling system: supply manual controlling cabinet and SIEMENS PLC touch screen controlling.

For the parts of ppr pipe making machine

• Changzhou GUOMAO gearbox,china best quality single screw extruder gearbox

• SIEMENS motor, motor famous all over the world;

• FUJI inverter (also can choose ABB inverter)

• RKC temperature meter (also can choose OMRON temp produce in Japan

ppr pipe making machine process:

Mixing -- vacuum feeding -- material dryness --single screw extruder -- single screw extruder -- single screw extruder -- color string extruder -- spiral co-extrusion mould --calibrator -- spray vacuum calibration tank -- spray cooling water tank -- spray-code printer -- belt haul-off -- no-dust cutter –Pipe Stacker for package;

If you want get more information, please contact us, thanks!

Our company is near Shanghai ,about150km. Contact person :Sarah He

Whatsapp/Facebook:+86 188629865739

Mobile:0086-18862985739

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece

Recommended Categories

Explore top categories and find suppliers for your specific needs-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.