Home > Products > differencial slip shaft > expanding friction differential air shaft for slitting machine

expanding friction differential air shaft for slitting machine

50 - 200

/ Piece

1 Piece(Min.Order)

- 2000 Piece / Pieces per Month

- shanghai

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 7 days

You May Like

-

expanding friction differential air shaft for slitting machine

-

3 inch ball type winding unwinding stainless steel slip differential friction air shaft for slitting machine

-

Key strip type friction shaft for reel cutting machine

-

High Precision Printing Machine parts Safety chucks

-

High Precision Printing Machine parts Safety chucks

-

Hot Sale Air Expanding Chucks Air Expanding Shaft Pneumatic Adapter

Product Details

| Brand Name | zhele | Place of Origin | China | |

| Model Number | zhele 016 | Material | Aluminium | |

| Length | 1-6m | Structure | Flexible | |

| Coatings | Other, chrome |

Product Description

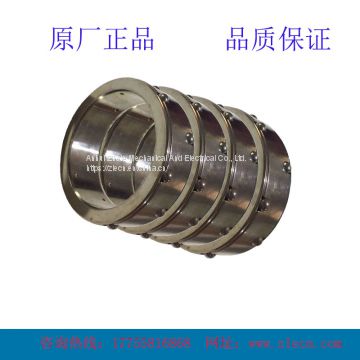

Stainless steel differential air shaft for slitting machine

2.Application of differential air shaft

A.The applicable Machine

It is used for slitting machine,coating machine,cutting machine,printing machine,compounding machine,paper making machine,bag making machine, embossing machine and so on .It can greatly improve the working efficiency and the quality of products.

B.The applicable Material

Differential air shaft has been widely used in plastic film including electronic, capacitor, battery film, plastic wrap,packaging,

composite film, metal foil such as copper foil and aluminum foil, paper and pvc sheet.

3.The advantages of our products

1). High quality material for the base shaft and spare parts

The body of the differential shaft is made from steel or stainless steel.We will check the surface roughness,straightness, dynamic

balance,cylindrical and so on to make sure it's qualified to use.

The friction plate can be made from polyurethane, polyethylene,or rubber.They has good consistency of dynamic and static friction

coefficient, less affected by temperature ,high wear resistance and long service life.It's good to realize max tension

required.And we can customize according to customer’s drawing or special requirement.

2).Surface Treatment

Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting.

The overall quenching and tempering treatment improve the wear resistance and corrosion resistance,which make it possible to use in a variety of environment.

3). Quality control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make

sure each shaft is qualified.

1). High quality material for the base shaft and spare parts

The body of the differential shaft is made from steel or stainless steel.We will check the surface roughness,straightness, dynamic

balance,cylindrical and so on to make sure it's qualified to use.

The friction plate can be made from polyurethane, polyethylene,or rubber.They has good consistency of dynamic and static friction

coefficient, less affected by temperature ,high wear resistance and long service life.It's good to realize max tension

required.And we can customize according to customer’s drawing or special requirement.

2).Surface Treatment

Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting.

The overall quenching and tempering treatment improve the wear resistance and corrosion resistance,which make it possible to use in a variety of environment.

3). Quality control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make

sure each shaft is qualified.

Detailed Images

Feature of Air Differential Rewinding Core Shafts

* Difference in material thickness often arises when unwinding plastic films or other material. In the process of constant winding, this difference can lead to obvious discrepancy in outside diameter of roll, and slight discrepancy in winding torque under this situation.

* After some winding rotation, some rolls may become very tight, and meanwhile, some other rolls may start to loosen, leasing to quality decline in product eventually.

* Our differential air shaft with slipping friction can ensure the highest winding quality, and by keeping proper tension on all rolls throughout the winding operation, materials will not show any problem.

* It works under the theory that friction rings slip constantly in center of air shaft, and to keep same tension, some rings slip faster than others. So tension of each roll can be controlled accurately, and permanent tension can also be gained to guarantee the quality of roll.

* According to different roll diameters, to control air pressure of air bag and to guarantee tension, a constant air pressure source kept by rotary joint is required

* Difference in material thickness often arises when unwinding plastic films or other material. In the process of constant winding, this difference can lead to obvious discrepancy in outside diameter of roll, and slight discrepancy in winding torque under this situation.

* After some winding rotation, some rolls may become very tight, and meanwhile, some other rolls may start to loosen, leasing to quality decline in product eventually.

* Our differential air shaft with slipping friction can ensure the highest winding quality, and by keeping proper tension on all rolls throughout the winding operation, materials will not show any problem.

* It works under the theory that friction rings slip constantly in center of air shaft, and to keep same tension, some rings slip faster than others. So tension of each roll can be controlled accurately, and permanent tension can also be gained to guarantee the quality of roll.

* According to different roll diameters, to control air pressure of air bag and to guarantee tension, a constant air pressure source kept by rotary joint is required

Size Chart of This Design

Contact Us

- Anhui Zhele Mechanical And Electrical Co., Ltd.

- Contact namefang Chat Now

- AddressfunanCITY, Fuyang, Anhui

Product Categories

| shaft | difference slip shaft | alumininum airshaft | aluminum guide roller |

| differencial slip shaft | shafty chuck | aluminum air expanding shaft |

New Products

-

Aluminum Anodization Key Type Air Expanding Shaft

-

Competitive Price Safety Chuck For Air Shaft China Safety Chuck Manufacturer

-

Manufacturer 28#/35#/50#/75# Safety Chuck For Pneumatic Shaft

-

Manufacturer 28#/35#/50#/75# Safety Chuck For Pneumatic Shaft

-

High Precision Printing Machine parts Safety chucks

-

High Precision Printing Machine parts Safety chucks

-

Manufacturer 28#/35#/50#/75# Safety Chuck For Pneumatic ShaftHot Sale safety chucks for air shaft for foam machine and Printing Machines

-

Foot mounting air expanding shaft work with safety chucks stainless steel 35# for expanding air shaft

-

Spindle seat 50# safety chuck (STO/STW) with foot mounting

-

Supplying square drive 22-30mm supplying safety chucks with flange mounted FLO/FLW for machine

-

Factory direct sell safety chucks with manual brake

-

Spare parts for air shaft textile machine-safety chucks series

-

China factory price air shaft manufacturers hot selling air shaft expanding chuck and industrial precision safety chuck

-

Hot sell spindle seat shaft seat type safety chuck/expanding chuck

-

Supplying High Precision safety chucks work with lug type air expanding shaft for printing machine

-

Supplying High Precision safety chucks work with lug type air expanding shaft for printing machine

-

Supplying High Precision safety chucks work with lug type air expanding shaft for printing machine

-

Square-Mouth Size Safety Chuck STO/STW35

-

Key strip type friction shaft for reel cutting machine

-

Flim blowing machine custom steel textile printing machine roller of printing and packaging industry

-

Customized rotogravure printing cylinder for printing machine

-

Customized rotogravure printing cylinder for printing machine

-

conveyor aluminum guide roller idler roller custom

-

Guide roller Aluminum Alloy Guide Roller For Printing Machine

Popular Searches

- spare parts

- Machine Part

- drive shaft

- transmission shaft

- packing machine

- printing machine

- axle

- air expanding shaft

- roller shaft

- Tension Controller

- aluminum shaft

- Carbon Fiber Shaft

- shaft sleeve

- core chuck

- safety chuck

- air steel

- Lug Type Air Shaft

- Expandable Shaft

- Key Type Air Shaft

- Shaft Collar

- Expansion Shaft

- Friction Shaft

- Differential Shaft

Recommended Products

- Conveyor Drive Rollers and Idler Rollers

- Anilox Rollers for Flexo Printing

- Silver Hard Anodized Aluminum Roll -

- Silver Hard Anodized Aluminum Roll -

- Hard Anodized Aluminum Roller Manufacturer & Seller ...

- Hard Anodized Aluminum Guide Roller for Mask Making Machinery

- Aluminium Hard Anodized Aluminum Roller

- Long life ceramic anilox roll for coating machine

- Offset flexo printing machine spare parts engraving Anilox Roll anilox plate flexo anilox cylinder

- Battery coating roller

- Ceramic anilox roller for offset printing machine

- Ceramic anilox roller for offset printing machine

Find Similar Products By Category

- Industrial Equipment & Components > Shaft > Metal Shaft

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Anhui Zhele Mechanical And Electrical Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

fang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

fang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile