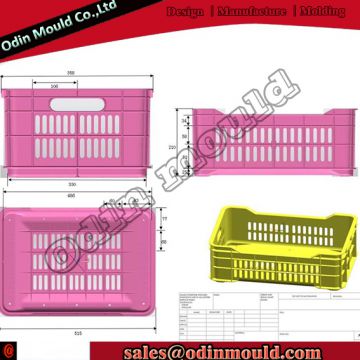

crates are common in everyday life and are mostly used in the transportation industry. For customers who want to start the Crate project, we can also provide with the crate injection molding production.

How to design the good crate injection mould?

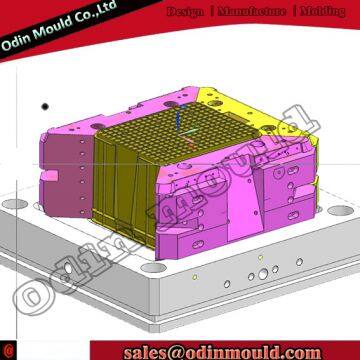

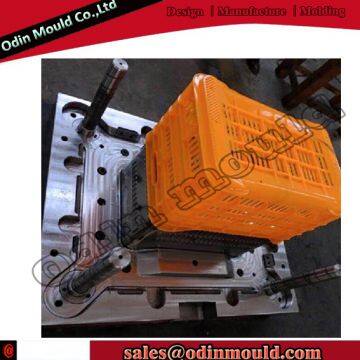

For the plastic crate mold, we pay more attention to the crate mold cooling system design. A good plastic filling system requires a special hot runner system to assist with molding to ensure optimal cooling. In order to produce a durable crate mold, the cooling water path on the largest forming surface of the mold must be optimized, and the tempered steel must be used with the excellent cooling water circuit design. In addition, the air venting system at the handle of the trunk is also the focus of our design. When the container is under load, the handle at both ends is the key point. If the two handles on the mold are not vented properly, obvious seams will be left and the product will be easily damaged.

Why the turnover box with insert design has the following advantages?

1. Each part of the mosaic plastic mold can be processed independently, and the processing accuracy can be guaranteed. It is also possible to perform quenching and heat treatment separately. More flexible processing and heat treatment operations.

2. If the part of the mosaic plastic mold is damaged, the component can be replaced without causing the entire mold to be scrapped and reduced costs.

3. The material of each part of the mosaic plastic mold can be freely selected according to requirements. Some core components or easily damaged components can be made of high hardness alloys to improve the service life of the mold.

4. The mosaic plastic mold can be disassembled, so the later maintenance is very convenient.

Mould Packaging & Delivery

Packaging Details:

1. Anti-rust oil

2. Plastic film

3. Wooden case

4. Or according to customer's requirement.

5.Port:Ningbo/Shanghai

6.Lead Time :40days

Odin Mould(atplas) is a professional manufacture of gas-assisted injection mold, daily-use plastics mould, SMC/BMC mould, thin-wall injection mold, injection molding OEM,we have cultivated an excellent team and established a comprehensive system to meet different Different needs of customers.

Name | Vegetable Bread Crate Injection Mould |

Brand Name | Odin MOULD |

Our Service | Mould Tool Manufacturing/Plastic Injection Moulding and OEM Services/Prototyping and 3D Printing/Assmebly. |

Value -added Services | DFM Report, Mould Flow, Mould Design,, QC Report, Injection Parameter Sheet, Testing Video. |

Standard | ISO9001:2008 |

Component Standard | Local, HASCO, DME, MiSUMI....etc |

Mould Base | LKM Mould Base...etc |

Mould Material | P20/718/738/NAK80/S136/H13/H13...etc |

Runner | Hot Tip/Cold Runner...etcSMC/BMC Mould: heating oil or electirc |

Product Material | ABS/PP/PC/PE/PA/POM/NYLON/TPU/PVC/PMMA/PLA...etc |

Painting Color | Customized |

Send Inquiry to This Supplier

You May Also Like

-

Plastic Cone Bobbin Injection MouldUS$ 1 - 999999MOQ: 1 Piece

-

Water Faucet Injection Plastic MoldUS$ 1 - 999999MOQ: 1 Piece

-

25t To 3000t Pvc Fitting Making Machine Pvc Injection Moulding MachineUS$ 15,000 - 45,000MOQ: 1 Set

-

Wholesale M80064 Injection Mounding Grade HDPE Virgin Recycled Granules for Injection Moulded Cases Crates Trays PailsUS$ 1300 - 1400MOQ: 2 Tons

-

Injection Moulding Machine Material Pa6 / Pa66 Pp Chrome Plating SurfaceNegotiableMOQ: 100 Pieces

-

Shenzhen Runpeng Custom Injection Moulding Plastic PartsNegotiableMOQ: 1

-

High Flow High Impact High Gloss ABS 750SW Injection Moulded Food Grade Fiber Appliance Parts Injection Moulded High Flow ABSUS$ 1.42 - 1.50MOQ: 1000 Kilograms

-

High Quality Industrial Pull Out Warehouse Storage Shelves Drawer Mould Rack With Lifting Crane Mold Drawer Roll Out Rack for Injection MouldNegotiableMOQ: 1 Set

-

Hot Sale Abs Pellets High Impact Resistance Injection Moulding Abs Granules for Auto PartsUS$ 0.7 - 1MOQ: 25 Kilograms

-

Industrial Air-cooled Chillers Chillers Chillers Mould Injection Molding Machines Water-cooled Chillers EquipmentCNY 3950 - 6000MOQ: 1 Piece