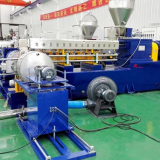

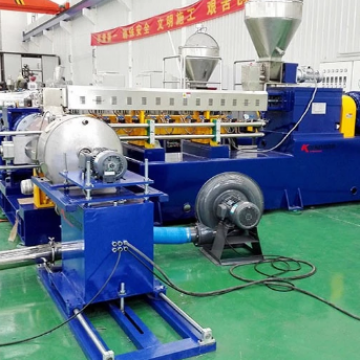

PVC LSHF compound making machine with Two Stages extruder

Typical Features

First stage is GL series co-rotating twin-screw mixer,using twin-screw high speed, high shear and strong hybrid advantage,makes material fully plasticized and mixed.

Second stage is SJ series single screw extruder. The characteristics of low speed and deep groove provide low shear processing environment, and coupled with barrel cooling, prevent the plasticised material from overheating decomposition phenomenon during high-pressure extrusion.

Applies to :

All kinds of heat-sensitive materials processing, such as PVC,XLPE, LSHF low smoke zero halogen flame retardant cable, shielding material etc.

Application for two stages extruders pelletizing machine (cascade extruders)

1. Plastic recycling: PP plastic bags recycling, PE film recycling

2. Cable material:PVC cable, PVC transparent bottle material, LDPE/HDPE/LLDPE crosslinked cable material

3. Anti-flame(flame retardant) masterbatch: LSHF

PP/ABS/PS/EVA/PA+Mg(OH)2(magnesium hydroxide)/Al2(OH)3 (aluminum hydroxide)

1. Q: How about Gongle Rubber &Plastic Machinery Co., Ltd. ?

A: Jiangsu Gongle Rubber&Plastic Machinery Co., Ltd. is a factory and also a company. We are specialized in this field for more than 30 years. At the same time we manufacture screw elements and barrel in our own factory.

2. Q: How long is the guarantee?

A: 12 months guarantee will be effective from the date of commissioning or 15 months from delivery.

3. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou, Jiangsu Province, China,which is quite near Shanghai Airport

All our clients, from domestic or abroad, are warmly welcome to visit us!

4. How about after-service?

We do provide life-long technical consultancy and spare parts. Cost-free direction installation. Normally like Turkey, Thailand, USA etc, we go there for exhibition, at the same time we will visit customers’ factory for machine troubleshooting and maintenance

PVC compound making machine with Two Stages extruder Description

compound granulator machine is advanced designed and manufactured with the latest processing machines and the most skillful workers. The smart automatic controling system ensures the best mixing and granulating performance during the plastic extrusion process. The extruder machine plastic, plastic extrusion machine is also designed with different auxiliary systems, which enables its multi-usage. It can process new plastic grnaules and also for used plastic recycling and granulating, like pp pe pet pvc ldpe and etc. The oversea service team helps the installatiopn, technical support and spare parts, which will ensure the continious production and longest lifespan.

Kneader

| model | mixing capacity | motor | feed way | unload way | weight | dimension |

| X(S)N-150l | 150L | 200kw | back or front | mechanical or hydraulic reverse | 21000kg | 4400*3500*4200 |

| X(S)N-110L | 110L | 160kw | back or front | mechanical or hydraulic reverse | 14000kg | 4200*3200*3500 |

| X(S)N-95L | 95L | 132kw | back or front | mechanical or hydraulic reverse | 13000kg | 4000*2724*3400 |

| X(S)N-75L | 75L | 110kw | back or front | mechanical or hydraulic reverse mechanical | 11500kg | 3673*2700*3400 |

| X(S)N-55L | 55L | 75kw | back or front | mechanical or hydraulic reverse | 8000kg | 3650*2700*3200 |

| X(S)N-35L | 35L | 55kw | back or front | mechanical or hydraulic reverse | 6500kg | 3100*2700*3200 |

| X(S)N-20L | 20L | 37kw | front | mechanical reverse | 2000kg | 2850*1950*2550 |

| X(S)N-5L | 5L | 7.5kw | front | mechanical reverse | 1200kg | 1500*800*2000 |

| X(S)N-3L | 3L | 5.5kw | front | mechanical reverse | 1000kg | 1500*900*200 |

compound granulator machine

Send Inquiry to This Supplier

You May Also Like

-

Nylon Spandex Fabric for Gold Costumes Women and Girl Wear Dance Clothes Performance Clothing Jazz&LatinUS$ 100 - 300MOQ: 1 Roll

-

Nylon Spandex Fabric for Bikini Solid Golden Sexy Slimming Plus Size Women SwimsuitUS$ 100 - 300MOQ: 1 Roll

-

Floral Printed Fabric 80% Nylon Polyamide 20% Spandex Fabric Seamless Fabric For CostumeUS$ 100 - 300MOQ: 1 Roll

-

Floral Printed Fabric 80% Nylon Polyamide 20% Spandex Fabric Seamless Fabric For Women's Elegant ClothingUS$ 100 - 300MOQ: 1 Roll

-

Nylon Rayon/Viscose Spandex Elastane FabricUS$ 100 - 300MOQ: 1 Roll

-

Printed Lycra 80+20% Nylon Spandex Fabric for Small Floral Fabric Printed 100% Twill Fabric For DressingUS$ 100 - 300MOQ: 1 Roll

-

Printed Lycra 80+20% Nylon Spandex Fabric for Floral Fabric Printed 100% Twill Fabric For DressingUS$ 100 - 300MOQ: 1 Roll

-

Customized 82% Nylon18% Spandex High Stretch Glossy Round High Shiny Lycra Fabric For Underwear SleepwearUS$ 100 - 300MOQ: 1 Roll

-

Stretch 85% Polyester 15% Spandex Glossy Shiny Fashion Fabric Sexy Swimsuit Satin Fabric For Sleepwear BraUS$ 100 - 300MOQ: 1 Roll

-

Shiny Holographic Reflective Snake Foil Elastane Nylon Spandex Fabric Sexy Swimwear Bikini Dance Dresses BeachwearUS$ 100 - 300MOQ: 1 Roll