Home > Products > Graphite Electrode > Anti Oxidation Coating Uhp 300mm 450mm 600mm Graphite Electrode

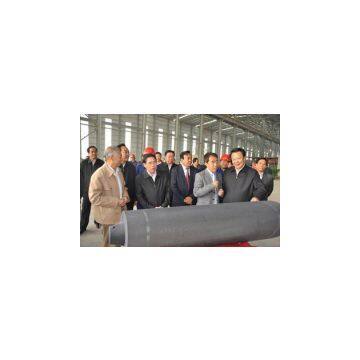

Anti Oxidation Coating Uhp 300mm 450mm 600mm Graphite Electrode

- HeBei

- T/T L/C D/P D/A Other

- 15 days

You May Like

-

Molded Graphite Heat Exchanger Graphite Block Pyrolytic Graphite Block

-

For Gold Or Silver Smelting Preferred Orientation Pure Graphite

-

Pure Graphite High Strength Graphitized For Industry / Cathodic Protection

-

For Arc Furnace Of Steel Factory High Purity Vibrating Carbon Graphite Block

-

0.8mm Heat Exchanger Ultra-pure Product Ultra High Thermal Conductivity

-

Preferred Orientation For Industry / Cathodic Protection Anti-oxidation

Product Details

| Brand Name | Sanneng | Place of Origin | China | |

| Model Number | UHP/HP/RP | Diameter | 200-350 | |

| Length | 1500mm-2700mm | Grade | UHP (Ultra High Power) | |

| Type | Electrode Block | Application | Arc furnace of steel-making | |

| Flexural Strength (N/㎡) | 10-14Mpa | Thermal Expansion | 1.1-1.4 | |

| Apparent Density (g/cm³ ) | cm³ ): 1.68-1.75g/cm3 | Resistance (μΩ.m) | 4.8-5.8μΩm |

Product Description

I plant the production of high-power graphite electrode, ultra-high power graphite electrode. Raw materials selected high-quality needle-shaped coke through high-pressure molding, calcination, graphite, machining, such as a set of production. Suitable for steel mills, foundries, smelters, with low resistance, high resistance strength, high density, low ash and other advantages, our factory graphite products have antioxidant, low ton consumption and other advantages.

Graphite electrode is a major conduction material used in the electric smelting industry, which has the properties of superior electric conductivity ,thermal conductivity ,high mechanical strength, oxidation and corrosion resistance in high temperature .Graphite electrode is typically used in EAF (for smelting steel),submerged arc furnace (for producing ferroalloy ,pure silicon, phosphor, matte ,calcium carbide ,etc. And electric resistance furnace ,such as graphitization furnace producing graphite electrodes, glass-melting furnace ,electric furnaces producing carborundum, etc.

Graphite electrodes are classified into RP,HD,HP and UHP.

Item | Unit | Ordinary power graphite electrode | High power graphite electrode | Ultra High Power | Electrode joint | ||

I | II | I | II | I | |||

The diameter | mm | 100-350 | 400-500 | 200-350 | 400-500 | 250-500 | 200-500 |

Than the resistance | μΩm | 6-9 | 7-10 | 6-7 | 6-7 | 4-5 | 4-7 |

Flexural strength | Mpa | 10-12 | 6.5-10 | 10-15 | 10-13 | 12-22 | 12-20 |

Modulus of elasticity | Gpa | 7-9 | 7-9.3 | 9-12 | 9-12 | 12-15 | 12-14 |

The compressive strength | /℃ | 1.8-2.9* 10-6 | 1.7-2.9* 10-6 | 1.6-2.2* 10-6 | 1.5-2.2* 10-6 | 1.4-2.2* 10-6 | 1.5-2.2* 10-6 |

Mpa | 18-22 | 18-22 | 24-28 | 24-26 | 24-26 | 32-38 | |

Notes of the use of graphite electrode

1.The electrode holder should be held in the place beyond the security line of the top electrode;otherwise, the electrode would be easily broken.the contact surface between the holder and the electrode should be cleaned up regularly to maintain a good contacting,the cooling jacket of the holder shall be avoided from water leakage.

2.Identify the reasons it there is gap in the electrode junction,do not use them until the gap is eliminated.

3.If there is falling off of nipple bolt when connecting electrodes,it is necessary to complete the nipple bolt.

4.The application of electrode should avoid of tilting operation, particularly , the gr.oup of connected electrodes should not be put horizontally so as to prevent from breaking.

5.When charging materials to the furnace,the bulk materials should be charged to the place of the furnace bottom,so as to minimize the impact of the large furnace materials on the electrodes.

6.The large pieces of insulation materials should be avoided of stacking on the bottom of the electrodes when smelting .so as to prevent from affecting the electrode use,or even broken.

7.Avoid of collapsing the furnace lid when rising or dropping the electrodes,which may result in electrode damage.

8.It is necessary to prevent the steel slag from splashing to the threads of the electrodes or nipple stored in the smelting site,which may damage the precision of the threads.

Contact Us

- Linzhang Sanneng Carbon Co. LTD

Product Categories

New Products

-

Pyrolytic Graphite Block High Density Graphite Block For Gold Or Silver Smelting

-

Solid Graphite Block Vibrating Carbon Graphite Block Low Ash Vibration

-

Anti-oxidation For Gold Or Silver Smelting Ultra High Electrical Conductivity

-

High Compression High Compression Strength Graphite Material

-

Ultra High Electrical Conductivity For Gold Or Silver Smelting Solid Graphite Block

-

Can Be Customized Ultra-pure Product High Density Graphite Block

-

Ultra High Electrical Conductivity Graphite Material For Glass Industry

-

Ultra High Thermal Conductivity Anti-oxidation For Industry / Cathodic Protection

-

For Industry / Cathodic Protection High Compression Strength Pure Graphite

-

Graphite Anode Rod High Density Graphite Block Solid Graphite Block

-

0.8mm Heat Exchanger Ultra High Electrical Conductivity Ultra-pure Product

-

Ultra High Thermal Conductivity High Purity For Industry / Cathodic Protection

-

For Gold Or Silver Smelting High Density Graphite Block Pyrolytic Graphite Block

-

Pure Graphite Ultra High Electrical Conductivity Can Be Customized

-

Carbon Graphite Block Heat Exchanger Graphite Block For Industry / Cathodic Protection

-

Molded Graphite Low Thermal Resistance Pure Graphite

-

For Gold Or Silver Smelting Pyrolytic Graphite Block Preferred Orientation

-

Low Ash Vibration Preferred Orientation Pure Graphite

-

Graphite Anode Rod Graphite Material Vibrating Carbon Graphite Block

-

For Blast Furnace Bottom Refractory Lining Preferred Orientation Carbon Graphite Block

-

High Compression Vibrating Carbon Graphite Block High Purity

-

Low Thermal Resistance For Arc Furnace Of Steel Factory Pyrolytic Graphite Block

-

Molded Graphite Ultra High Electrical Conductivity Pyrolytic Graphite Block

-

Vibrating Carbon Graphite Block High Purity High Compression

Popular Searches

- heating element

- graphite electrode

- electric fireplace

- hot plate

- annealing furnace

- induction furnace

- melting furnace

- smelting furnace

- induction heating

- heat treatment

- heating equipment

- tempering furnace

- industrial furnace

- vacuum furnace

- eaf

- small electric arc furnace

- smelt

- small capacity

- eaf electric arc furnace

- graphite powder

- graphite block

- anode

- welding electrode

- carbon electrode

- graphite block electrode

- graphite rod electrode

- arc electrode

- cathode

- carbon anode

- rp graphite electrode

Recommended Products

- Graphite Electrode, Graphite Crucible, Graphite Block, Graphite Plate, Graphite Rod, Graphite Manufacturer Quality Assurance Price Discount

- Graphite Electrode

- Graphite Products Manufacturers in Chin

- Sythetic Graphite Sheet With 0.025mm

- UHP Graphite Electrode

- HP Graphite Electrode

- RP Graphite Electrode

- Graphite Electrode Nipple

- Graphite Electrode Thread

- Graphite Crucible

- Graphite Nine Hole Crucible

- Graphite Sagger

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Graphite & Products > Graphite Electrode

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile