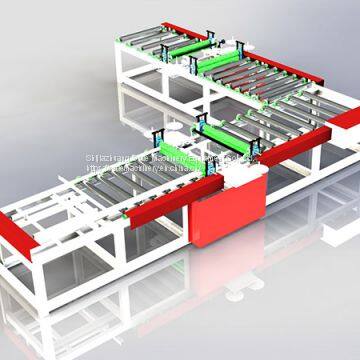

Edge Banding Machine

- 10 Set / Sets per Month

- Tianjin

- T/T L/C D/P D/A Credit Card PayPal Other

- 20 days

You May Like

Product Details

| Brand Name | Sude Machinery | Place of Origin | China | |

| Dimension(L*W*H) | length 4.3m × width 0.831m × height 0.7m length 3m × width 0.831m × height 0.7m | Power | 4.5KW | |

| Condition | New | Automatic Grade | Automatic | |

| Packaging Material | Wood | Packaging Type | Case |

Product Description

Specification:

The edge banding machine is an alternative to the manual edge sealing procedure: conveying - glued edge - cutting - front and rear head - up and down trimming - up and down finishing edge - up and down scraping - polishing is highly automated The machine is mainly divided into semi-automatic and portable.

The edge banding machine is a kind of woodworking machinery.

The edge banding machine is one of the woodworking machinery. It belongs to the solid wood machinery category. The edge banding machine is used for edge sealing. The traditional manual process is done with highly automated machinery.

Including the straight-faced profiled edge in the conveying - glued edge - cut - front and rear head - up and down trimming - up and down finishing edge - up and down scraping - polishing and many other processes.

Features

This machine is suitable for medium density fiberboard, blockboard, solid wood board, particle board, polymer door board, plywood and other straight edge trimming, etc. It can be double-coated with double-sided rubber edge banding and cutting edge banding. Head, chamfering, roughing, finishing

The function of scraping and polishing, the edge sealing is fine, smooth, and the hand feel is good, and the sealing line is straight and smooth. The equipment is stable, reliable, durable and affordable. It is especially suitable for large and medium-sized furniture, cabinets and other panel furniture manufacturers.

The function of each group:

Pre-milling: Double-milling cutters are used to modify the corrugation marks, burrs or non-perpendicular phenomena caused by the sawing and cutting saws to achieve better edge sealing effect. The sealing of the edge strip and the board is closer, and the integrity and the appearance are better.

Gluing and sealing: Through special structure, the edge-sealing board and the edge-sealing material are evenly coated on both sides to ensure a firmer adhesion.

Head-to-head: Through the precision linear guide motion, the automatic tracking of the master and the fast cutting structure of the high-frequency high-speed motor ensure the smooth and smooth cutting surface.

Intensive: Both adopt automatic model tracking and high-frequency high-speed motor structure to ensure the smoothness of the upper and lower parts of the trimmed plate. It is used to repair the excess edge banding material on the edge of the edge of the processing board. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding of panel furniture, and it is better to use edge banding of 0.8mm thick or more.

Scratch: It is used to eliminate the ripple marks caused by the cutting process of trimming non-linear motion, so that the upper and lower parts of the board are smoother and more tidy.

Polishing: The finished plate is cleaned with a cotton polishing wheel, and the edge of the edge is smoothed by polishing.

Slotting: It is used for directly grooving the side panels and bottom plates of the closet. The process of reducing the panel saw is more convenient and quicker; it can also be used for slotting the aluminum edging of the door panel.

Precautions

The main advantage of the curved edge banding machine is that the bonding is firm, fast, light and efficient. To achieve this effect, in addition to the good edge banding machine, you should also pay attention to the edge banding, hot melt adhesive, substrate, Elements such as work environment and method of operation.

Select the edge band to pay attention to the width, thickness, material, toughness, surface treatment and other factors. Hot melt adhesives should pay attention to the difference between high, medium and low temperature adhesives, and match the types of edge banding. It is also necessary to scientifically set the temperature to control the temperature and the flowability and solidification delay of the sol.

The selection of the substrate also has the requirements of mass, temperature, parallelism and perpendicularity of the cutting surface. The indoor temperature and dust concentration of the working environment also need to be considered, the speed of the substrate, the edge banding, the speed of the rubber shaft, the pressure, the balance, Coherence, etc. will affect the edge-sealing effect.

Fourth, the method of repairing the curved edge banding machine The curved straight edge banding machine will also have some problems and failures in use. Common faults are:

1. Electrical failure. Including the host stop, the temperature is not fast, the program is disordered, etc., if not eliminated in time, it will burn the motor and the heating tube, and even damage the entire mechanical system. Mainly check the electrical control box, motor, heating tube, delay device, etc. during maintenance. This type of overhaul is usually repaired by a professional or by a manufacturer's manufacturer.

2. The gas path is faulty. Including gas valve failure, air leakage, low air pressure, cutting knife, feeding does not work, etc., mainly check the integrity of various pneumatic components, replacement parts can be carried out under the guidance of the manufacturer's technical staff.

3. Mechanical failure. There are mainly transmission failures, uneven glue coating, feeding failure and cutter failure, etc., mainly checking the integrity and firm parts of the mechanical parts, and whether the transmission parts are offset.

4. Bonding failure. Such as sticking, deviation, entrainment, etc., this is a comprehensive fault, related to the rubber shaft, edge banding, sol, substrate and operation.

Such failures may occur alternately or in a single occurrence, depending on the situation.

Related product keywords:Edge Banding Machine Manufacturer

Contact Us

- Shijiazhuang Sude Machinery Equipment Co., Ltd.

- Contact nameLiu Zhanheng Chat Now

- Phone86-138-31181369

- AddressMita Road, Jinzhou City,, Shijiazhuang, Hebei

Product Categories

| products |

Popular Searches

- extrusion machine

- sealing machine

- woodworking machinery

- woodworking saw

- dust collector

- moulder

- wood grinder

- mdf flooring line

- Making Machine

- pvc profile

- woodworking tool

- edging machine

- edge bander

- pvc tape

- Pvc Edge Banding

- Trimming Machine

- Edge Bander Machine

- Woodworking Edge Banding Machine

- pvc sealing machine

- finger jointer

- woodworker

- Pvc Edge Banding Machine

- Wood Edge Banding Machine

- Edge Banding Bander Machine

- Corner Rounding Machine

- cnc machine

- edge bander

- Machine Line

- wood edge bander

- Trimming Machine

Recommended Products

- SR battery square aluminum shell coating machine

- Lithium battery automatic sealing machine

- Multi-Function Crackers Packaging Machine Automatic Industry Biscuit Packaging Machine

- Factory Direct High-Speed Multi-Function Pillow Packing Machines for Biscuits Bread Other Foods

- Horizontal Biscuit Cracker Flow Wrapping Biscuit Packaging Machine Price Packaging Machine For Cookies

- Automatic Cookies Packaging Machine Industry Biscuit Packaging Machine For Sale

- Multi-Function Biscuit Pillow Packaging Machine Biscuit Packaging Machine Automatic

- Biscuit Multi Head Weighing Packaging Machine/ Packaging Machine For Cookies

- Automatic Biscuit Packaging Machine/ Cracker Packing Equipment/ Cookies Packing Machinery

- Industry Biscuit Packaging Machine For Sale Cookies Form Fill Seal Wrapping Flow Packaging Packing Filling Sealing Machine

- Automatic Biscuit Multi Head Weighing Packaging Machine/Biscuits Pillow Packaging Machine For Cookies

- Automatic Flow Packing Machine Small Cookies Biscuit Packing Machine Biscuit Packaging Machine

Find Similar Products By Category

- Packaging & Printing > Packing Machinery > Multi-Function Packing Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Liu Zhanheng

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Liu Zhanheng

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile