TPHD1616 High Speed Spindle CNC Gantry Plate Drilling Tapping Milling Machine Metal

Main Features

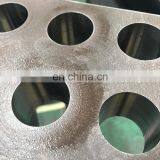

CNC slide way drilling spindle (Z axis) with work piece of stroke is pre-set, realized auto switch. It can drill not only through-hole, but also blind-hole with high efficiency, simple-structure, low-cost maintenance, easy operation etc.

There are 12 hydraulic clamps & T slots for fixing workpieces, easy to operate, also save time, improve production efficiency.

This machine have three CNC axis: gantry moving direction (x-axis);drilling head moving direction (y-axis); Spindle feeding direction (z axis). Machine equip each axis with linear guide and ball screw which drived by high precision servo motor.

Machine have scrap cleaner which collect iron scraps and cutting liquid.

The machine equipped with automatic lubrication system for linear guides and ball screws.

Machine adopts SIEMENS 808D system, also equip with computer for drawing and workpiece program processing, easy to operate.

The configuration of the machine, like ball screws, linear guides, main electrical parts, servo motors, inverter, etc., all famous brands.

Automatic lubrication system--This system will help lubricate the machine automatically, reduce the workload, provide better care and maintenance for the machine.

Electrical Cabinet With SIEMENS 808D System

Air-cooling device--This device help to keep the oil temperature, guarantee the operation of machine normally.

SNADVIK tools

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Send Inquiry to This Supplier

You May Also Like

-

ZSK4830 CNC Rotary Multi-station Drilling and Tapping MachineNegotiableMOQ: 1

-

USA Russia Israel Aluminum Profile Working 3 Axis Cnc Milling Machine for SaleUS$ 8,980 - 23,900MOQ: 1 Set

-

6"(180mm) Professional Air Angle GrinderNegotiableMOQ: 30 Pieces

-

Square Column Vertical Drilling MachineNegotiableMOQ: 1 Set

-

.1WX ROTARY TRENCHING HOLEBORERNegotiableMOQ: 1 Set

-

Y24 Service Unmounted Rock Dill ToolUS$ 1 - 1,000MOQ: 1 Set

-

Snake Shape Drill Magnetic StandUS$ 10 - 11MOQ: 50 Pieces

-

Global Supplying Auger TorqueUS$ 2,300 - 4,000MOQ: 1 Set

-

Metal Crawler Parts,metal Crawler for Drilling Machines,crawler Drilling RigUS$ 9,000 - 9,800MOQ: 1 Set

-

TG360 High Quality Low Price Air Tapping MachineUS$ 415 - 520MOQ: 10 Pieces