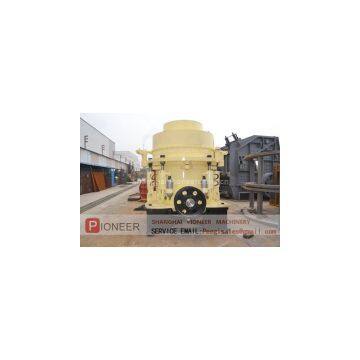

Features of hydraulic cone crusher

1. The best cavity designand adjustable stroke

HP cone crushers can be easily adjusted fordifferent production requirements. With a wide selection of cavities, the samecrusher can be used in 2nd, 3rd or 4th crushing stages, producing different endproduct sizes, and meets the different demands of customers.

2. The advanced automatic control device

Pioneer adopts the form of IC50 automation systemwith electronic touch screen of automatic control plate. The IC50 automationsystem offers a variety of control modes for various production requirements.Machines can operate with a fixed setting to achieve constant output gradation.The automation system can also automatically adjust the closed side setting tocompensate the wear under load, ensuring that the optimum setting is alwaysused. If reduction work needs to be maximized, the IC50 automation system canautomatically and continuously adjust the setting to keep power draw andcrushing force at the desired levels.

3. High-techparts

The reliability and safe operation of the HP cone crushers are the result,among other things, of their high quality steel. Their reliability in demandingcrushing applications and on-going development projects involving manganesematerials and metallurgical compounds.

4. Simplemaintenance and convenient in operation

All parts of HP cone crushers can be assembled,disassembled and repaired from the top and side parts, including the fixed coneand movable cone. It is no need to disassembled and install the frame, andfasten bolts, so HP cone crusher is much more convenient and fast for replacingliner plates. The crusher production efficiency will be much better by usingthe hydraulic motor.

5. Latest detailed design

Pioneer continual to research and develop thecrushing technology and equipment, uses the simple floating shaft designconcept to ensure reliability of equipment, and adopts the super large diameterspindle and heavy-duty main frame to make equipment more strong and durable.

6. Full process adaptability

HP cone crushersare designed to give maximum performance in a wide variety of crushingprocesses: from secondary to extra fine crushing, and from stationary to highlymobile applications. Full process adaptability is the result of being able touse several different crushing cavities in the same frame structure. This featureensures that you are always able to adapt your HP to the crushing process

TEL:0086-21-60273583

FAX:0086-21-60273582

Email:pioneer88mac@gmail.com

Skype: machineinfo8

ADDR:No.12, Jinshun Road, Airport Industrial Zone, Pudong New District, Shanghai,China

Website:

Send Inquiry to This Supplier

You May Also Like

-

Hot Selling Plastic Crusher Plastic Barrel Oil Pot Crusher Large Plastic Products CrusherUS$ 2460.00MOQ: 1 Cubic Meter

-

Professional Services HRC55 Solid Carbide End Mills Tools for MillingUS$ 1 - 5MOQ: 1 Set

-

Beverage Cans Multiple Shredder Big Blue Barrel CrusherUS$ 5333 - 53333MOQ: 1 Set

-

Plastic Shearing CrusherUS$ 20,000 - 80,000MOQ: 1 Set

-

NEW Waste Plastic Grind MachineUS$ 5,000 - 10,000MOQ: 1 Set

-

Solid Waste Shredding MachineUS$ 1,000 - 5,000MOQ: 1 Set

-

High Performance Powerful Recycling Machine Plastic CrusherUS$ 1,500 - 20,000MOQ: 1 Set

-

Professional PET Flakes PET Plastic Crushing and Washing MachineNegotiableMOQ: 1 Set

-

Rubber SealNegotiableMOQ: 1 Set

-

Women Riding SportswearNegotiableMOQ: 1 Set