Home > Products > New product > Tungsten Carbide Welding Blade

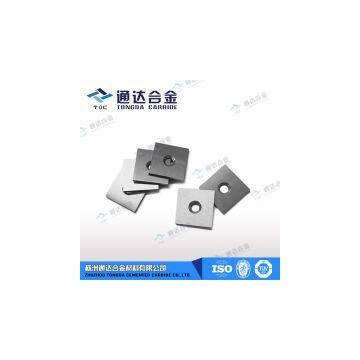

Tungsten Carbide Welding Blade

- 1000000 Piece / Pieces per Month

- T/T L/C D/P D/A

- 7 days

You May Like

Product Details

| Brand Name | TDC | Place of Origin | China | |

Product Description

Tungsten carbide welding blade using finer than the raw powder YG6 and YG8 ensure product abrasion resistance, cast iron and nonferrous metal finishing and semi-finishing of choice. Its wear resistance and allows higher cutting speed YG6 and YG8. tungsten carbide blades for welding steel and stainless steel processing characteristics, the scientific selection of alloy composition and structure, supplemented by the production process optimization, make better universal properties of the alloy, the scope is wider, can be used for steel, stainless steel, semi-finishing and light load roughing; selection of quality ultrafine tungsten carbide powder, so that the wear resistance, impact resistance, thermal shock resistance, good combination. tungsten carbide welding blade for cast iron, nonferrous metals, heat-resistant metals, semi-finished titanium alloys, high impact resistance, the need for continuous and broken cutting.

Key points of tungsten carbide welding blades:

1、Welding cutting tool structure should have sufficient rigidity

Is rigid enough to allow the maximum dimension and the use of high strength steel and heat treatment to be guaranteed.

2、Tungsten carbide blade should be fixed firmly

Carbide welding blade should be fixed firmly enough to the extent that it is on a knife slots and to ensure the quality of welding, so you want to choose a blade inserts groove shape according to the shape of the blade and tool geometry parameters.

3、carefully check Arbor

Before the blade welded to the shank of the blade needs, Arbor carry out the necessary checks, first check the blade bearing surface can not have a serious bent. Carbide welding surface may not have serious carburized layer, should also be Carbide Arbor blade surface and dirt tank inserts were cleared to ensure the welding firm.

4、Rational use of solder

In order to ensure the welding strength, you should choose a suitable solder in the soldering process, should ensure good wetting and liquidity, and the exclusion of air bubbles, making welding and alloy welding face full contact, no shortage of welding phenomenon.

Contact Us

- Zhuzhou Tongda Cemented Carbide Co. Ltd

- Contact nameDemi Ma Chat Now

- Phone86-731-28164321

- Address, Rizhao, Shandong

Product Categories

| New product |

New Products

-

Tungsten Carbide Indexable Inserts WNMG

-

Tungsten Carbide Indexable Inserts YBC151

-

Tungsten Carbide Indexable Inserts YBG302

-

Tungsten Carbide End Mills

-

Micro Grain Carbide 2 Flute End Mills

-

Micro Grain Carbide 4 Flute End Mills

-

Micro Grain Carbide 2 Flute Ball Nose End Mills

-

Micro Grain Solid Carbide Long Flute 2 Flute Square End Mills

-

Micro Grain Carbide Long Shank 2 Flute Ball Nose End Mills

-

Micro Grain Carbide 2 Flute Corner Radius End Mills

-

Micro Grain Carbide 4 Flute Corner Radius End Mills

-

Tungsten Carbide Ball Mill Jar

Popular Searches

- zinc ingot

- Zinc Alloy Ingot

- Pure Zinc Ingot

- Zinc Ingots

- Zinc

- Alloy Zinc

- cold steel plate

- zinc ingot manufacturers

- zinc ingot metal

- zinc ingots 99.99%

- ms steel plate

- Ppgi Roofing Sheet

- Spte Sheet

- electro galvanize

- zinc dross

- Structural Steel Sheet

- zinc ingot price

- Zinc Alloy Ingot Zamak

- misprinted tinplate sheets

- zinc metal ingots

- import wholesale electronics

- zinc anode

- zinc sacrificial anode

- zinc alloy anode

- Aluminum Anode

- Wear Steel Plate

- misprinted sheets

- zinc scrap ingot

- ship building steel

- plastic mold steel

Recommended Products

- ASTM F136 B265 Tc23 Gr29 Gr2 Seawater Corrosion Resistant Hull Material Titanium Plate

- Optimal Price High Quality Iron Steel Factory Best Quality Hot Dipped Galvanized Steel Plate Corrosion Resistant A283 C70 S355 200mm Wide AISI 1045

- Incoloy 800/800h/800ht High Temperature Corrosion Resistant Nickel Base Alloy Plate

- Tin Corten Ss400 High Strength Wear Checkered A36 304 Ms Hot Rolled Mild Galvanized Stainless Carbon Steel Brass Copper Titanium Alloy Plate Price

- ASTM Tc3 Tc2 Tc11 Hot Rolled Titanium Alloy Steel Cold Rolled Plate for Ship

- 304 316 310S A36 Ss400 SPCC SGCC Cold Rolled/Stainless/Titanium/Wear Resistant/Carbon Hastelloy/Monell Alloy/Aluminum/Copper/Galvanized/ Steel Plate

- Tin Corten Ss400 High Strength Wear Checkered A36 304 Ms Hot Rolled Mild Galvanized Stainless Carbon Steel Brass Copper Titanium Alloy Plate Price

- High Quality Titanium Plate ASTM B265 Titanium Plate Gr1 Gr2 Gr3 Gr5 Price Per Kg Pure Titanium or Alloy Sheet

- Titanium Nickel Alloy Nitinol Sheets/nickel Titanium Shape Alloy Sheet/Nitinol Alloy Plate

- Best Selling Manufacturers with Low Price and High Quality Titanium-plated Stainless Steel Plate

- Gr1 Gr2 Gr5 Titanium Plate Gr1 Gr2 Gr4 Astm B265 Porous Titanium Sheet/Plate

- Titanium Plate Gr1 Gr2 Gr3 Gr4 Gr5 Factory Wholesale High-Performance Titanium Plate

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Sheet & Plate

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Demi Ma

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Demi Ma

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile