Home > Products > New product > Tungsten Carbide Saw Blades

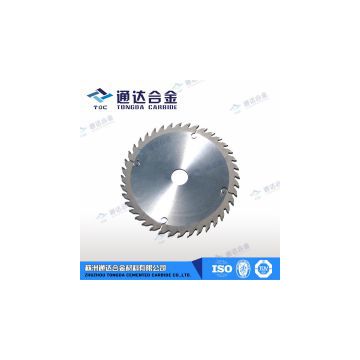

Tungsten Carbide Saw Blades

- T/T L/C D/P D/A

- 7 days

You May Like

Product Details

| Brand Name | TDC | Place of Origin | China | |

Product Description

What is Tungsten Carbide Saw Blade?

Tungsten carbide saw blades can be simplified as TCT saw blades. Tungsten carbide saw blade is the most commonly used wood products processing cutting tools. The quality of carbide saw blade and processing are closely related. Reasonable selection of carbide saw blades is important for improving product quality ,shortening the processing time, reducing processing costs. Tungsten carbide saw blade contains the type of substrate material, diameter, number of teeth, thickness, profile, angle, aperture and other parameters, which determine the processing capacity and cutting blade. Selecting the blade for cutting materials should take the type, thickness, cutting speed, cutting direction, feed speed, road width of the need into consideration.

Proper use of tungsten carbide saw blade.

Basic requirements of TCT saw blades:

According to equipment design and select the most appropriate carbide saw blade.

The equipment shall be equipped with safety devices, such as: protective cover, power brakes, overload protection.

installation, and wear work clothes, wearing goggles, earmuffs etc. should be operated under a professional operator

Operators can not wear gloves, and long hair should be put inside the cap in order to prevent danger.

Away from fire and humid environment.

Installation requirements of tungsten carbide saw blades:

the equipment should be in good condition. No distortion in spindle, no path hop, no vibration and so on.

checking the state of blade, tooth is complete, the saw plate is smooth and clean, and presence of other anomalies, in order to ensure safe use.

direction of the arrow blade should be the same with spindle rotation direction when assembly.

saw the installation to maintain the axis, a chuck and flange for cleaning, blade flange diameter and the same diameter, flange and blade to ensure close integration of pins installed, tighten the nut. Flange size should be appropriate, shall not be less than the diameter of the saw blade diameter of 1 / 3.

Before starting the device, the safety of the situation should be ensured. A single person should operate equipment, jog idling, check the device is turned to the right without vibration, and the saw blade should be installed a few minutes after the first spin.

Contact Us

- Zhuzhou Tongda Cemented Carbide Co. Ltd

- Contact nameDemi Ma Chat Now

- Phone86-731-28164321

- Address, Rizhao, Shandong

Product Categories

| New product |

New Products

-

Tungsten Carbide Indexable Inserts CNMG

-

Tungsten Carbide Indexable Inserts SNMG

-

Tungsten Carbide Indexable Inserts TNMG

-

Tungsten Carbide Indexable Inserts WNMG

-

Tungsten Carbide Indexable Inserts YBC151

-

Tungsten Carbide Indexable Inserts YBG302

-

Tungsten Carbide End Mills

-

Micro Grain Carbide 2 Flute End Mills

-

Micro Grain Carbide 4 Flute End Mills

-

Micro Grain Carbide 2 Flute Ball Nose End Mills

-

Micro Grain Solid Carbide Long Flute 2 Flute Square End Mills

-

Micro Grain Carbide Long Shank 2 Flute Ball Nose End Mills

Popular Searches

- zinc ingot

- Zinc Alloy Ingot

- Pure Zinc Ingot

- Zinc Ingots

- Zinc

- Alloy Zinc

- cold steel plate

- zinc ingot manufacturers

- zinc ingot metal

- zinc ingots 99.99%

- ms steel plate

- Ppgi Roofing Sheet

- Spte Sheet

- electro galvanize

- zinc dross

- Structural Steel Sheet

- zinc ingot price

- Zinc Alloy Ingot Zamak

- misprinted tinplate sheets

- zinc metal ingots

- import wholesale electronics

- zinc anode

- zinc sacrificial anode

- zinc alloy anode

- Aluminum Anode

- Wear Steel Plate

- misprinted sheets

- zinc scrap ingot

- ship building steel

- plastic mold steel

Recommended Products

- MR Grade Tinplate Sheet T1-T5 Hardness T1-T5 Tinplate for Can Manufacturing

- ETP TFS Tinplate Manufacturer CA DR8 DR9 Electrolytic Tinplate Sheet Printed

- Tins Metal BA Tinplate Wholesale Electrolytic Matt Surface Tin Plate Tinplate Sheet

- MR Grade 0.18mm Thick Golden Lacquer Electrolytic Tin Plate Tinplate Sheet

- ETP CA BA Lacquer Tinplate Sheet T2 DR9 Electrolytic Tinplate Coil

- Tin Coated Steel Electrolytic Tinplate Bright Surface TinPlate Tinplate Sheet No reviews yet

- MR SPTE Grades T1 T5 Hard Tinplate Metal Coils Manufacturing Services for Hard Cutting Welding Processing

- Reliable Tinplate Supplier/Etp/Tfs/Spte Tinplate Food Packaging T3 TH550 Tinplate Sheet Coil

- MR Grade T5 T1 Hardness Tinplate Strip Coil for Food Cans Various Applications With Welding Cutting

- Prime Quality T3 T4 T5 Mr Tin Plate Sheet Printing Tinplate Coil for Tinplate Cans and Tinplate

- Prime Quality TMBP Tin Mill Black Plate Tinplate Sheet ETP Steel Coil Competitive Price for Can

- Etp Lacquer Tinplate Coil Tin Plate Sheet Bright Surface Food Grade Lacquer Tinplate

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Sheet & Plate

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Demi Ma

Hi there! Welcome to my shop. Let me know if you have any questions.

Demi Ma

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile